Floor Screed Machine HD 50 24

www.utiform.com departamento.técnico@utiform.com Tfno. + 34 96 570 29 82 Fax: + 34 96 570 29 83

2. Never open the electrical distribution cabinets, connection cells or other electrical equipment while the machine is

powered. If this is unavoidable, for example for measurements, test or adjustments, these jobs should be carried out

by an expert specialized electrician, using appropriate tools and observing the requisite safety measures.

3. The noise, although not very loud, may disturb or make us nervous and after some time our nervous system may

suffer considerable damage.

Depending on the sound pressure level in the workplace, the following provisions must be made:

- Less than 70 dB (A): no special precautions need be taken.

- Above dB (A): any persons who work continuously in this area should use auditory protection.

- Less than 85 dB (A): for sporadic visitors who spend a short time in the zone it is not necessary to take

any specific protective measures.

- Above 85 dB(A): Excessively noisy zone! A warning sign should be placed at the entry to this area

stating that auditory protection is compulsory – even for a short period -in the zone.

- Above dB(A): The warning signs at entry to the zone should indicate that sporadic visitors must wear

auditory protection

- Above 105 dB(A): special auditory protection must be supplied, adapted to the sound volume and the

spectral composition of the sound. There should be a warning sign to this effect at each entrance.

7.3 Check prior to start up

• Make sure that there is no one in the lifting zone close to the machinery with feed hopper and load shovel.

• Never fill with fuel when the diesel motor is functioning.

• Ensure the correct positioning of all the cables. Adequately secure all the risers of the transport hoses and check the

safety of the couplings in the hoses to ascertain that they are adequate and not faulty in any way.

7.3.1 Machine Safety Systems

Prior to starting up the machine, all the protective installations should be in place and they must be

ready to function correctly.

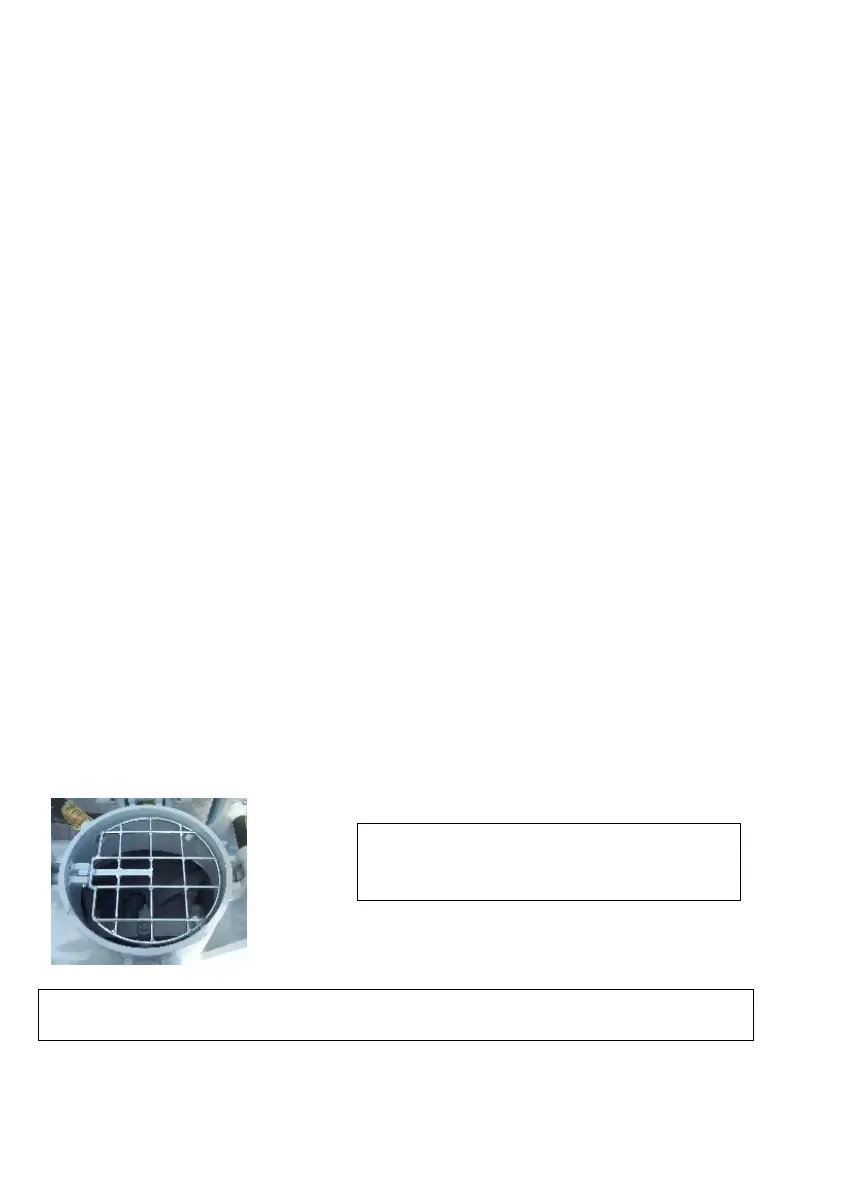

The HD-50/07machine complies with all European safety regulations and the machine is fitted with

all the necessary safety mechanisms such as the grille at the material mouth of the tank.

This grille has a double safety system, it has a butterfly screw which prevents the grille from lifting

off and if this screw is removed and the grille lifted, the machine will not function correctly, as air escapes

through this hole, and secondly the grille has an inductive sensor so that even if the grille comes off the

diesel motor (according to model) it stops automatically.

Never try to put your hand

through the safety grill !

In dangerous situations or when strange noises are heard, with the machine in operation quickly press the

emergency button to stop the machine immediately.

The button is restarted by turning it to the right and pulling outwards.

Loading...

Loading...