www.vac.se

92026r15

V200 POSITIONER

10

R

S

P

L

I

T

R

A

N

G

E

9

0

°

D

0

%

9

0

°

L

I

N

1

0

0

%

1

0

0

%

1

8

0

°

L

I

N

5

0

%

0

%

0

%

9

S

P

L

I

T

R

A

N

G

E

9

0

°

D

R

0

%

5

0

%

1

8

0

°

L

I

N

1

0

0

%

1

0

0

%

9

0

°

L

I

N

0

%

B

R

S

P

L

I

T

R

A

N

G

E

9

0

°

D

0

%

9

0

°

L

I

N

1

0

0

%

1

0

0

%

1

8

0

°

L

I

N

5

0

%

0

%

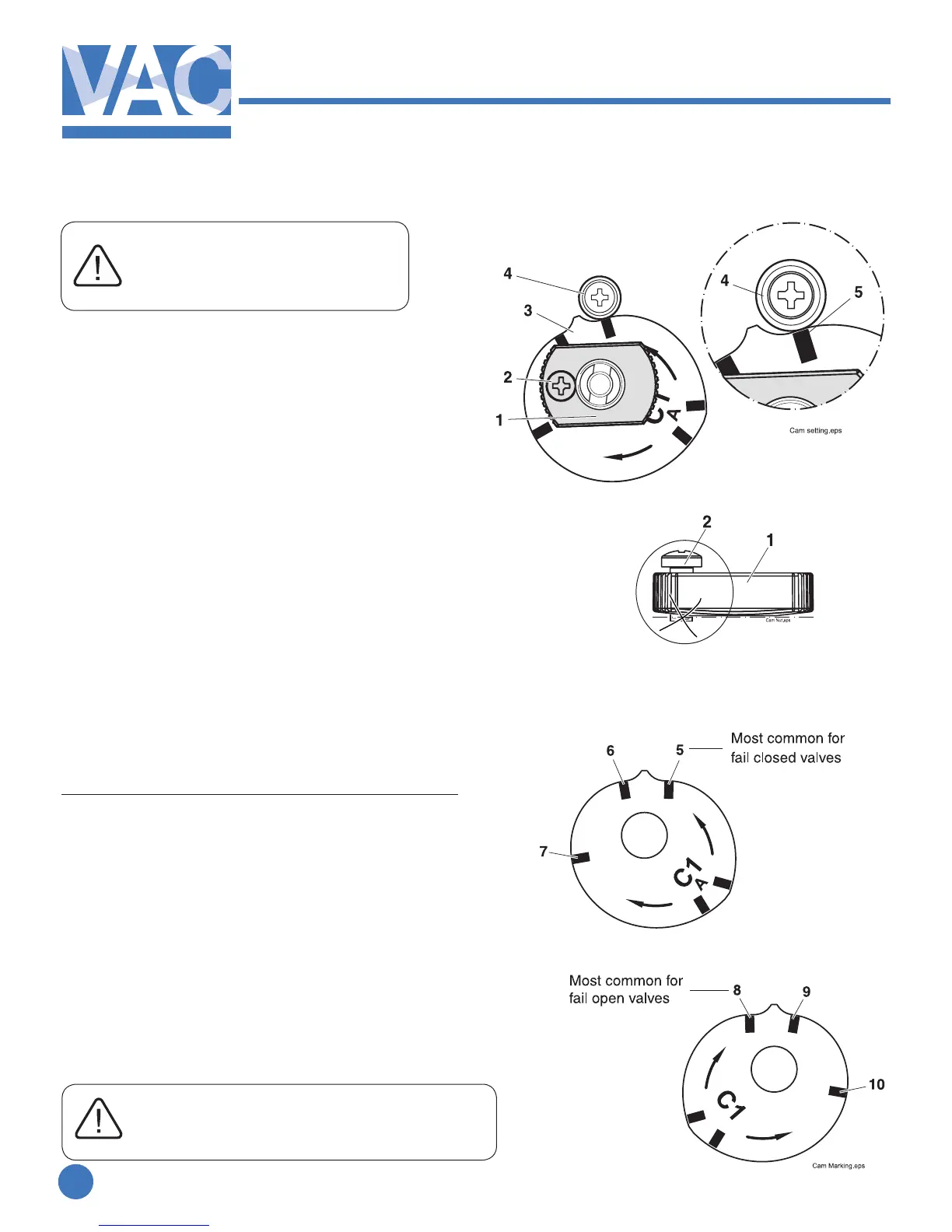

2.5 Cam

The V200 is standard shipped

with the C1-cam, factory set

for 90° ±1°, direct (CCW) turning.

2.5.1 Adjustments

Remove the front cover and indicator.

(see page 15)

1. Loosen the locking screw(2) and the cam

nut(1).

2.Strokethevalve/actuatortothestop/end

position at 0% input.

3. Turn the cam(3) so that the index mark(5)

for the selected curve aligns with the ball

bearing(4). A small gap between the roller and

the cam tip is desirable.

4. Tighten the cam nut by hand(1).

Check that the locking screw(2) is still loose.

(if not, loosen the locking screw slightly and

tighten the nut again).

5. Tighten the locking screw(2).

Do not tighten cam nut with screw(2) down.

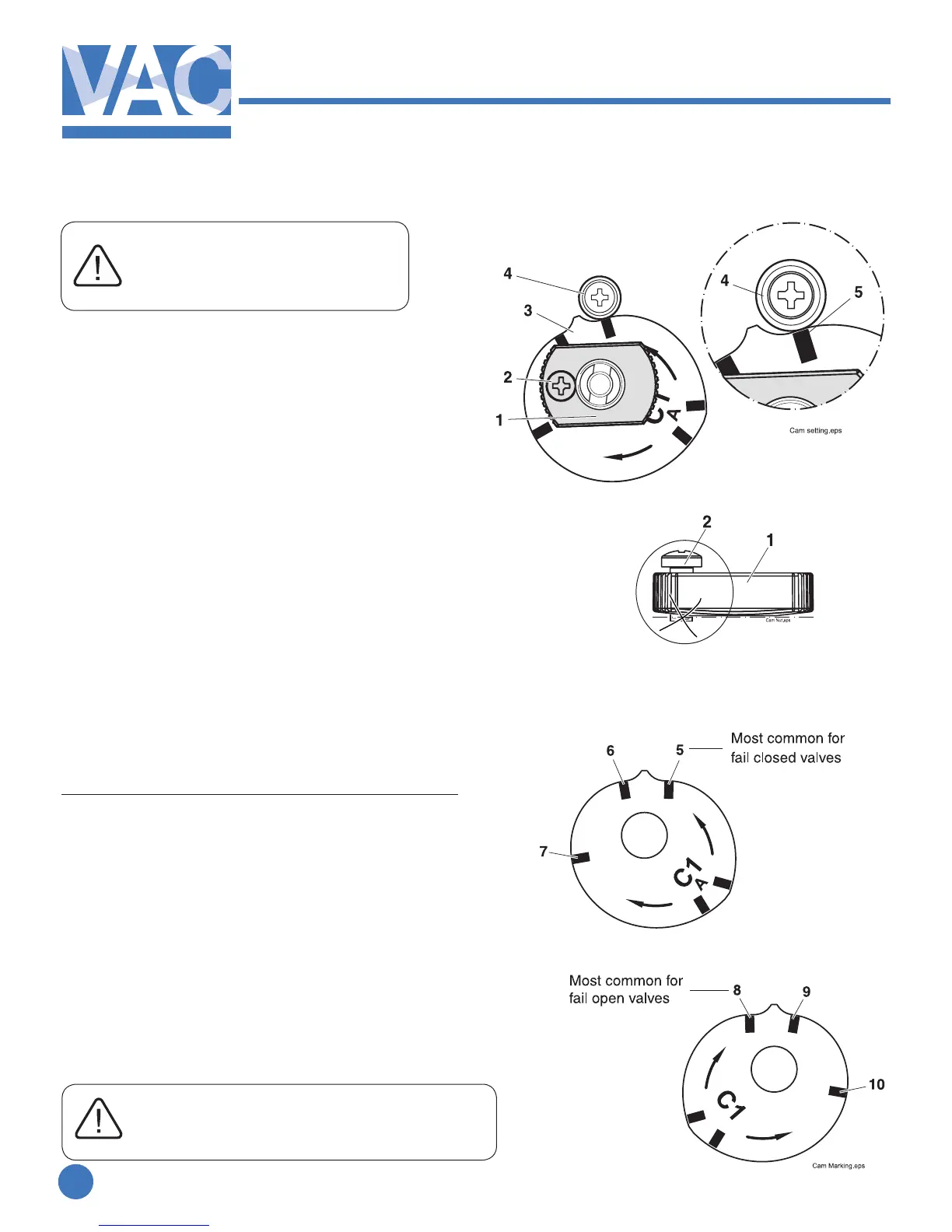

2.5.2 Cam specications C1

Indexmark/Startingpointofrotation*

5. 90° Linear 0-100% CCW

6. 180° Linear 0-100% CW

6. 90° Linear 0-50% CW split range

7. 90° Linear 50-100% CW split range

8. 90° Linear 0-100% CW

9. 180° Linear 0-100% CCW

10. 90° Linear 0-50% CCW split range

11. 90° Linear 50-100% CCW split range

*Increasingsignalrotation.

MostvalvesrotateCWtoclose/CCWtoopen

When eld reversing action of positioner

tubing must be reversed as well

(see page 7 and 8)

Loading...

Loading...