25ecoTEC plus 937 installation and maintenance manual

10

11

12

13

9

8

7

6

1

2

3

4

5

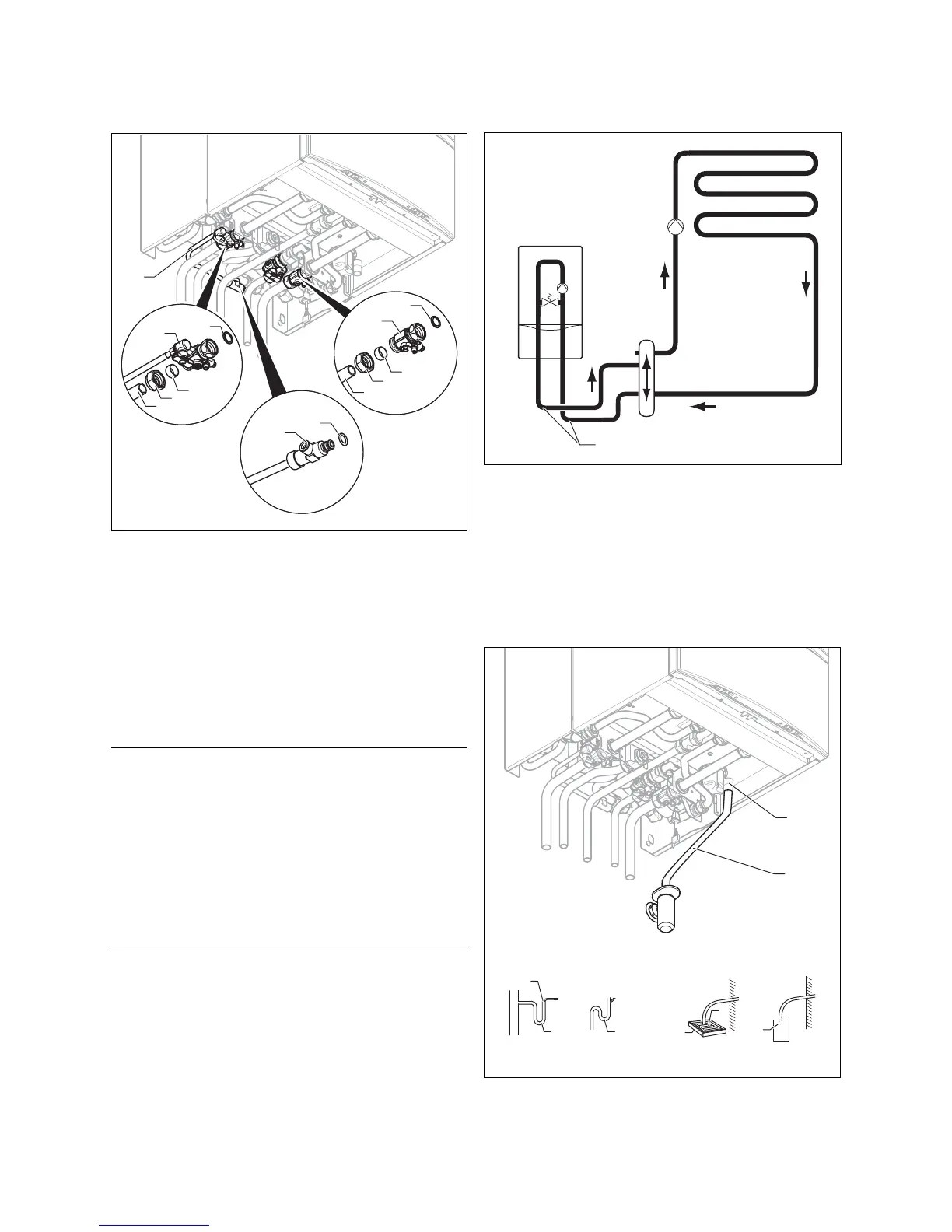

Fig. 4.9 Flow and return heating connections

• Remove the isolation valves with union nuts, olives

and fibre washers from the box of accessories for the

combi boiler.

• Insert the fibre washer (1) and screw the isolation

valve (2) onto the return pipe connection on the

combi boiler.

• Insert the fibre washer (10) and screw the isolation

valve (9) with the fitted flexible hose (13) onto the

flow connection of the combi boiler.

• Fit the O-ring seal (12) to the non-return valve (11).

h

Note!

Lay the filling loop hose (13) above the pipework

elbows.

• Push the union nuts (4) and (7) with olives (3) and (8)

onto the pre-shaped 22 mm pipes (5) and (6).

• Push the pipes (5) and (6) into the isolation valves up

to the stop. Tighten the union nuts in this position.

• Fit the handle for the filling loop to the cold water

isolation valve (9) with a countersunk screw.

a

Caution!

Please note that, when fitting a hydraulic

diverter the diameter of the connection lines

between the unit and the diverter must not be

greater than 22 mm.

Ø max. 22 mm

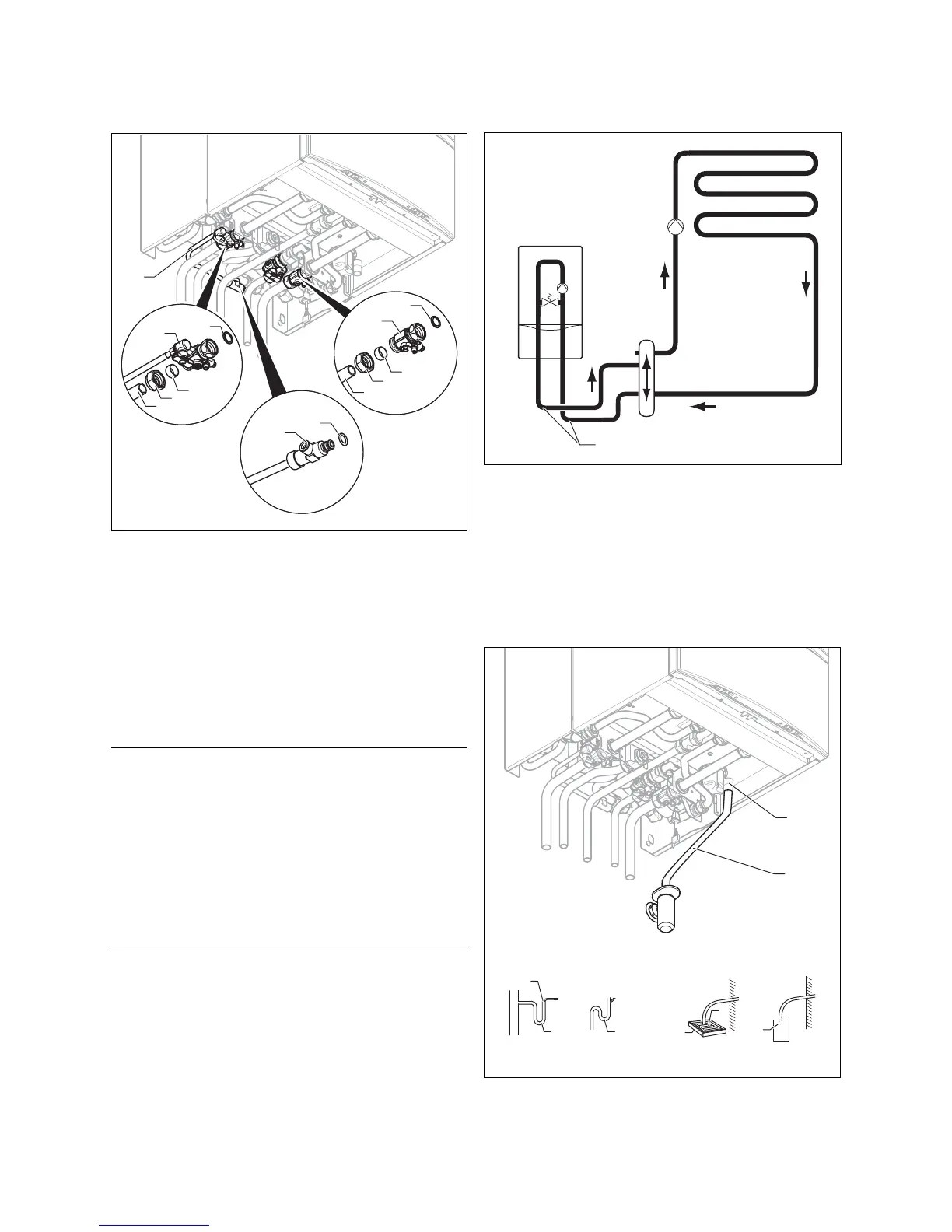

Fig. 4.10 Diameter of the connection lines when using a

hydraulic diverter

4.15 Condensate drain

The combi boiler is equipped with a condensate siphon.

(The filling height is 145 mm.) The siphon collects the

condensate in a vessel with a capacity of approx. 200 ml

and feeds the entire contents to the drain pipe. This

minimises the risk of the drain pipe freezing up.

1

2

7

d

c

6

5

a

3

4

3

b

Fig. 4.11 Installing the condensate drain

Sequence of operations during installation 4

Loading...

Loading...