Hydraulics installation 5

0020250180_00 geoTHERM Installation and maintenance instructions 17

▶ Inform the end user about the measures required for frost

protection.

5.6.2 Filling/refilling the heating installation

1. Open all of the thermostatic valves on the heating in-

stallation and, if required, all other isolation valves.

2. Check all of the connections and the entire heating in-

stallation for leaks.

3. To remove air pockets from the heating installation, use

a filling pump to rinse the heating installation. To do

this, fill the heat pump via the return line and allow the

water to flow out via the flow line.

5.7 Filling and purging the brine circuit

5.7.1 Mixing the brine fluid

The brine fluid consists of water mixed with a concentrated

antifreeze. The brine fluids that may be used differ greatly

from region to region. For more information, contact the re-

sponsible authorities.

Only ethylene glycol in the specified ratio is authorised by

Vaillant as a brine fluid for operating the heat pump.

Alternatively, suitable ready-mixed fluids for heat pumps can

be ordered from Vaillant.

▶ Carefully mix ethylene glycol with water.

– Ratio of ethylene glycol to water: 3:7

◁ This results in an aqueous solution with 30% vol.

ethylene glycol.

◁ The brine fluid is protected against frost.

– Frost protection for the brine fluid: −16 … −14 ℃

▶ Check the mixture ratio of the brine fluid.

– Working materials: Refractometer

5.7.2 Filling the brine circuit

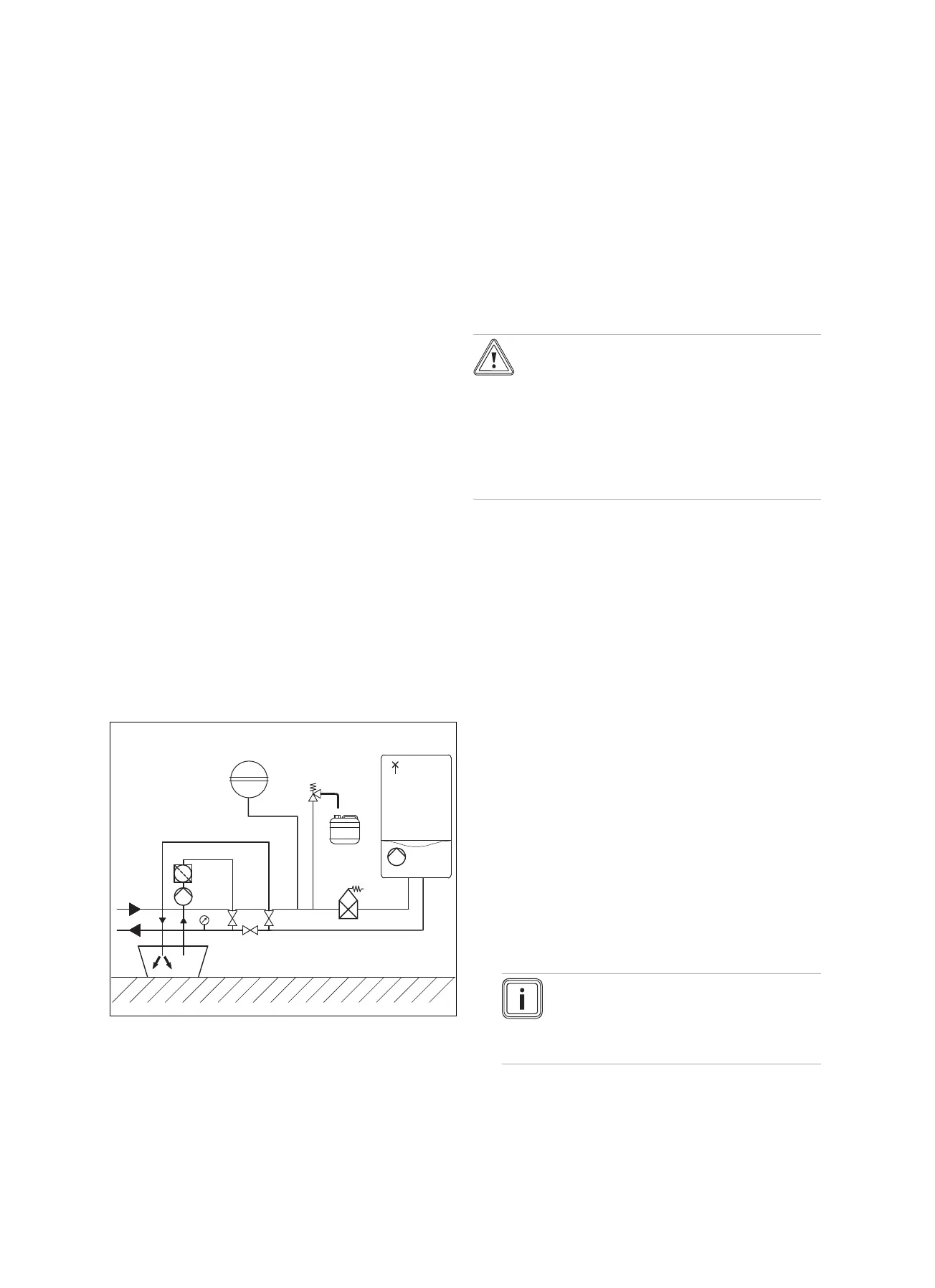

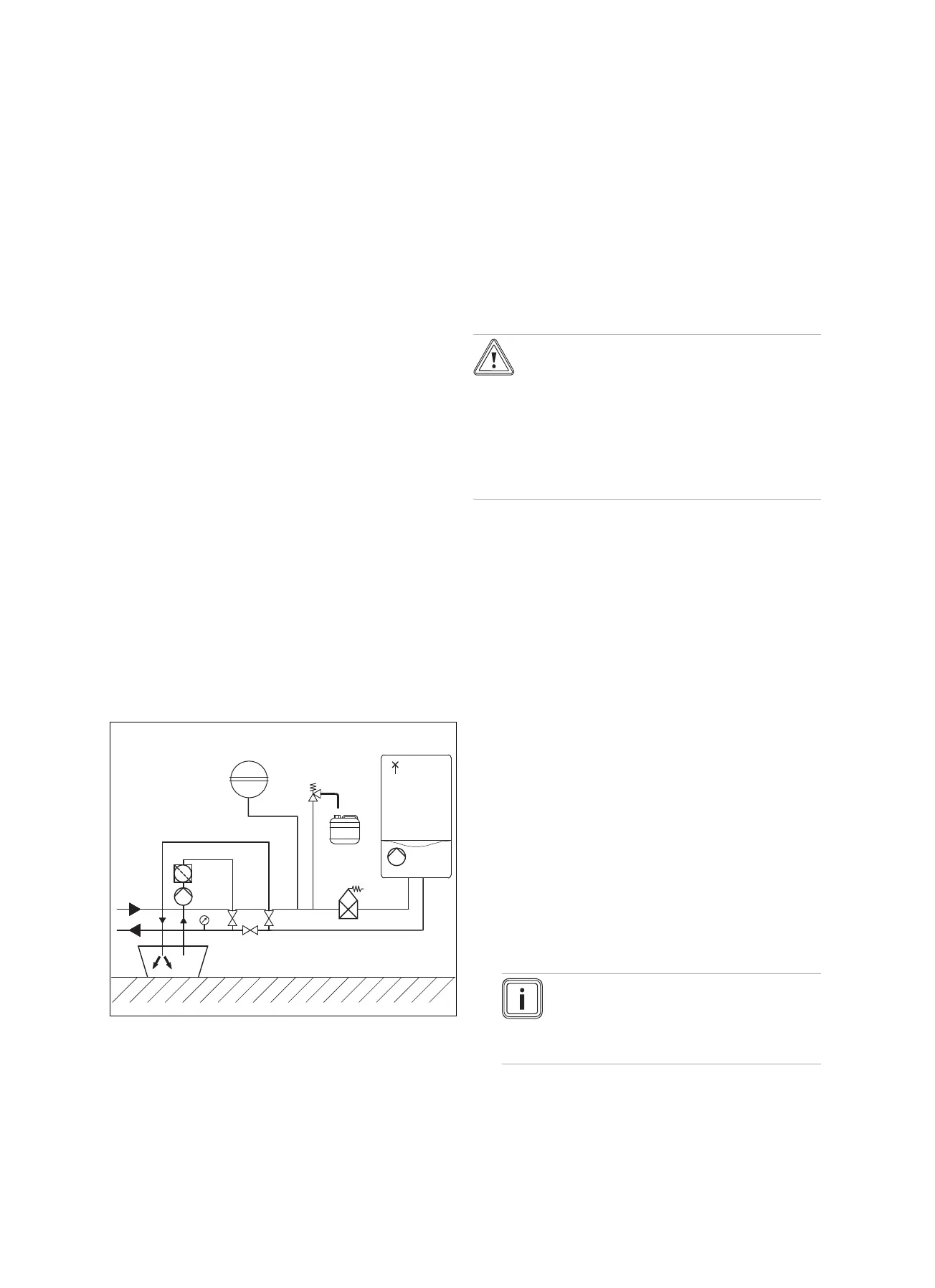

71

66

48

62

42a

63

61

33

67

65

A

B

69

29

37

29 Brine pump

33 Dirt filter

37 Automatic air separator

42a Expansion relief valve

48 Pressure gauge (op-

tional)

61 Stop valve

62 Stop valve

63 Stop valve

65 Brine collecting con-

tainer

66 Brine container

67 Filling pump

69 Purging screws

71 Expansion vessel

A From the heat source

to the heat pump (hot

brine)

B From the heat pump to

the heat source (cold

brine)

1. Install a dirt filter (33) in the pressure line.

2. Connect the filling pump's pressure line to the isolation

valve (61).

3. Close the isolation valve (63).

4. Open the isolation valve (61).

5. Connect a hose, which leads to the brine fluid, to the

isolation valve (62).

6. Open the isolation valve (62).

Caution.

Risk of material damage caused by an

incorrect filling direction.

If you fill the brine pump against the direction

of flow, this may lead to a turbine effect which

can damage the pump's electronics.

▶ Ensure that the brine pump is filled in the

direction of flow.

7. Use the filling pump (67) to pour the brine fluid from the

brine container (66) into the brine circuit.

– Brine fluid: Ethylene glycol/water ratio: 3/7

8. If you choke the filling pump, you can reduce the air

ingress into the brine circuit.

5.7.3 Purge the brine circuit

1. Start up the filling pump (67) in order to fill and rinse the

brine circuit.

2. Allow the filling pump (67) to run for at least 10 minutes

in order to fill and rinse the circuit sufficiently.

3. Then close the isolation valves (61) and (62) and switch

off the filling pump (67).

4. Open and close the purging valves (69) on the heat

pump and check whether air is still escaping.

5. Purge the heat pump completely in order to prevent

its functioning from being impaired by air in the brine

circuit.

6. Place a silicone hose (5 mm diameter) on the purging

valves and catch the brine fluid in a bucket.

7. If required, repeat this rinsing process.

8. Open the isolation valve (63).

5.7.4 Building up pressure in the brine circuit

1. Use the filling pump (67) to pressurise the brine circuit.

Note

To operate the brine circuit without any prob-

lems, a filling pressure of 0.15 MPa (1.5 bar)

is required. The expansion relief valve opens

at 0.3 MPa (3 bar).

2. Read off the pressure on the manometer.

Loading...

Loading...