7

4. PRELIMINARY CHECKS

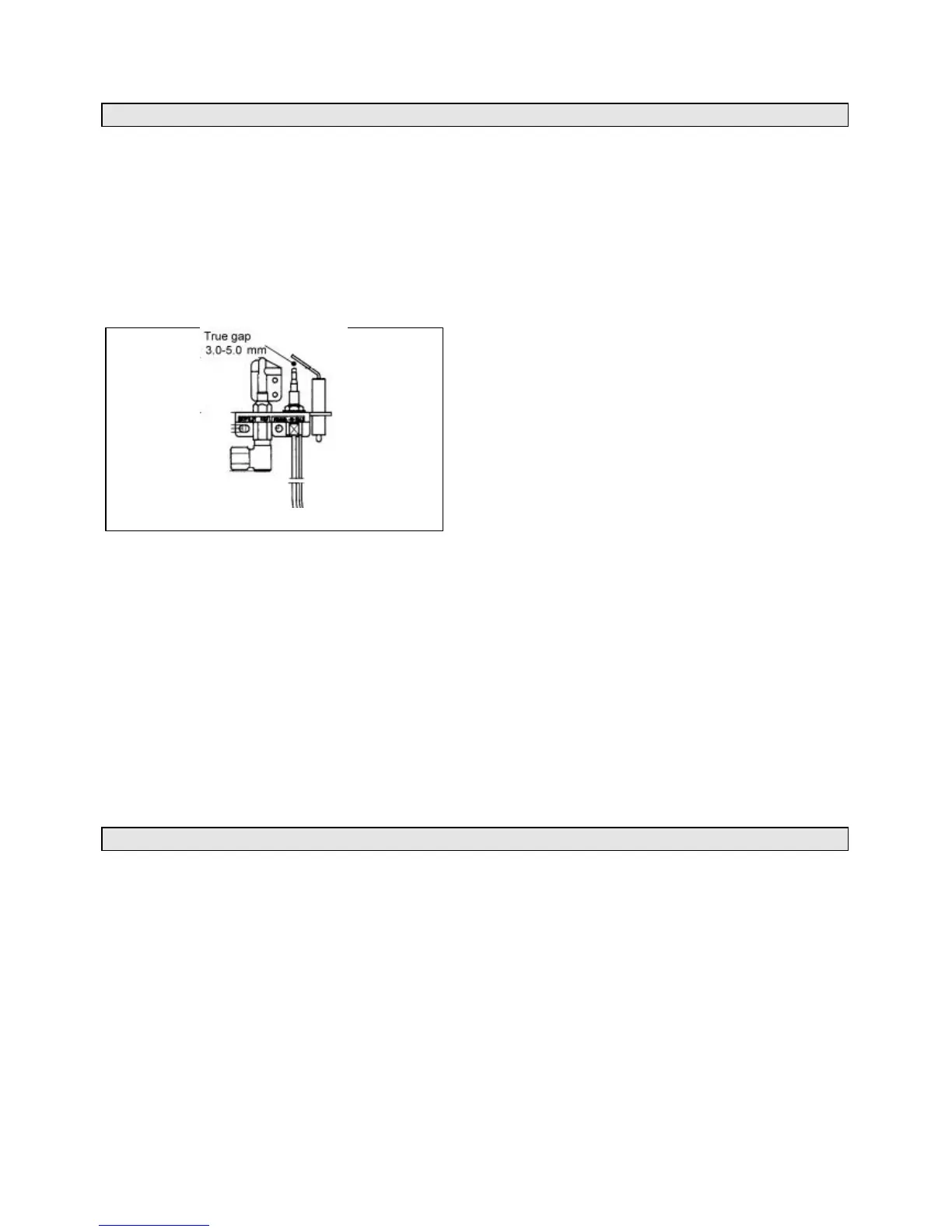

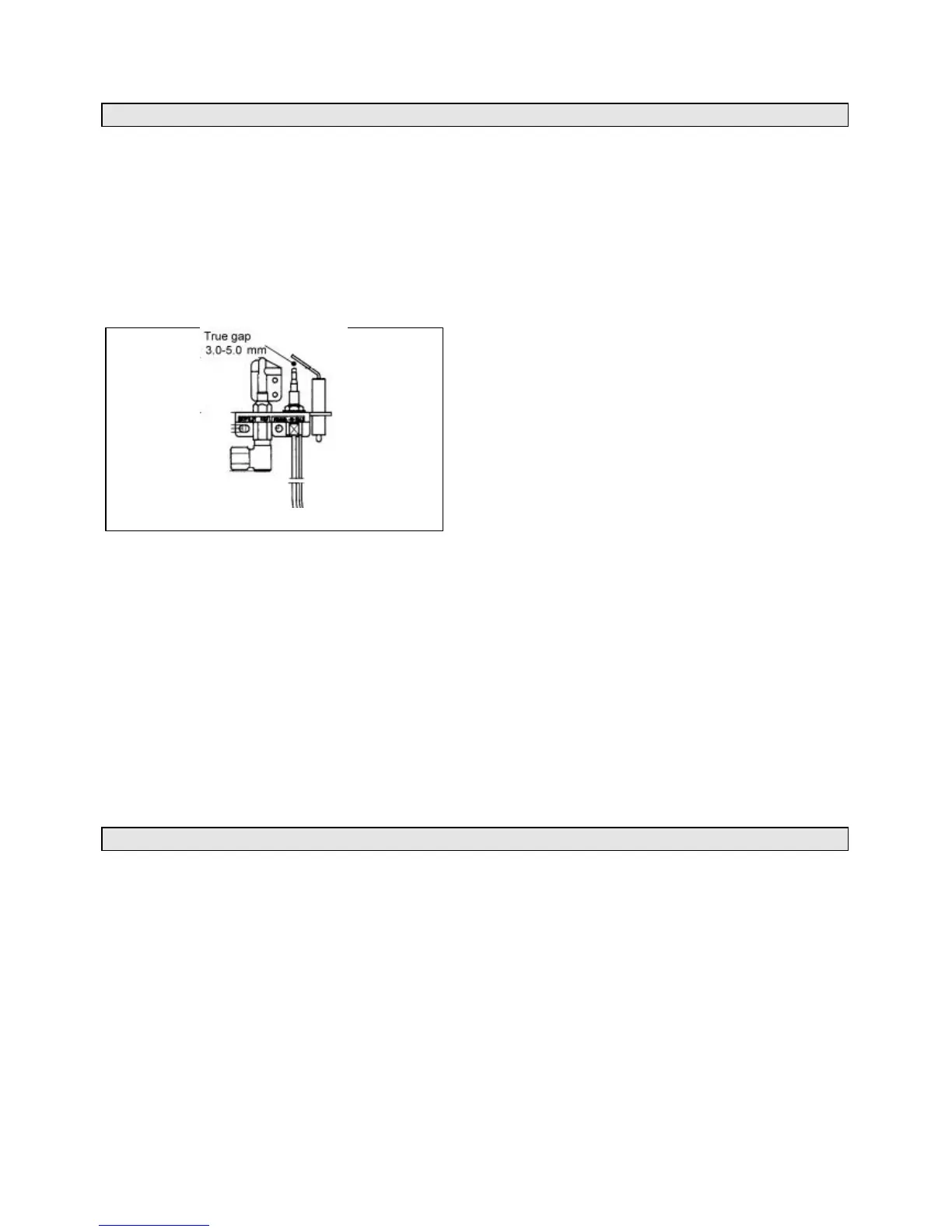

4.1 CHECK IGNITION SPARK

Before attempting to install, it is worth checking that the

piezo electric spark ignition system operates satisfactorily.

To initiate the spark, depress the control knob and while

keeping it depressed, turn anticlockwise through

approximately 60° to the “PILOT/IGN” position. A spark

should track from the electrode pin to the thermocouple

tip. If there is no spark or incorrect tracking, check the

spark gap between the electrode wire and thermocouple tip

(see figure 3). If the spark gap is correct, check the ignition

wiring.

4.2 CHECK THE FIREPLACE

The fireplace must comply with all the requirements of

section 2.

4.2.1 Fireplace general condition

The fireplace floor should be reasonably flat to ensure that

the convection box can be installed without it rocking and so

that a good seal can be made at the bottom front of the box.

The front face of the fireplace should be reasonably flat over

the area covered by the convection box top and side flange

seals to ensure good sealing. These faces should be made

good if necessary. If the appliance is to be fitted against a

wall with combustible cladding, the cladding must be

removed from the area covered by the outer surround (see

figure 1c). We suggest that the actual surround is used as a

template to mark the area for combustible cladding removal.

4.2.2 Soundness for appliance attachment

Two primary methods of retaining the appliance are

provided: -

1) By fixing to the fireplace front.

2) Using concealed tension cables fixed to the rear of the

fireplace opening together with secondary fixing to the

fireplace floor.

The methods are detailed in section 7 of this manual.

Before selecting the retention method, consult with the

customer. Method 2 is provided for instances where drilling

holes in the front surface of the fireplace surround is

unacceptable to the customer or otherwise impractical. N.B.

It is unwise to attempt to drill into marble without the

proper tools and equipment.

If method 1 is chosen, make sure that the fireplace front

surround area is sound enough to take the rawlplugs and

woodscrews. If necessary, make sound with a suitable

cement.

If method 2 is chosen, make sure that the areas at the back

and towards the centre of the fireplace floor are sound

enough to take the eyebolts and screws. If these areas have

deteriorated due to prolonged use, they should be made

sound with a suitable cement.

4.2.3 Installations using a metal flue box

The whole of the top surface of the metal flue box must be

covered with a layer of mineral wool or equivalent insulation

at least 100mm thick (see figure 1b).

4.3 FIREPLACE FLUE PULL

After preparing the fireplace, carry out the flue flow test as

detailed in BS5440: Part 1.

Note - A 13 gramme smoke pellet will generate the required

volume of smoke, anything smaller may give a false pass result.

Observe the smoke. If there is a definite flow into the

opening continue with the installation. If there is not a

definite flow, preheat the chimney for ten minutes and

recheck. If there is still no definite flow, the chimney may

need attention. Do not fit the appliance. Seek expert advice.

5. GAS SUPPLY CONNECTION

A nut and olive are provided for an 8mm pipe inlet

connection to the elbow at the bottom front of the

appliance. The elbow can be rotated to allow a connection

from any direction. The elbow includes a valve for isolating

the gas supply.

The supply pipe must be rigid material. Flexible pipe must

not be used.

5.1 CONCEALED SUPPLY PIPE

CONNECTION

If a concealed connection from inside the fireplace is

required then, before the appliance is fitted into the

fireplace it will be necessary to extend the supply line so

that it will project through the sealed opening at the back of

the convection box (near the left side) and run to the elbow

at the front

The pipe run from the supply line up to the rear opening in

the convection box must be kept clear of the area which will

be taken by the convection box when it is installed. A

template is supplied to aid the installation of the pipe run.

We recommend the following method for installing with a

concealed supply pipe:

5.1.1 Cut the template to the shape shown by the “Debris

catchment area”. Note that the areas are different for

fireplaces with conventional brick flues and precast flues.

5.1.2 Place the template on the fireplace floor (printed

side upward) with the front line level with the front surface

of the fireplace. The centre line of the template should line

up with the centre of the fireplace. Tape the template

securely in this position

5.1.3 Make sure that the fireplace is clear of all material

over the full area covered by the template including that

marked “Debris catchment area”.

Fig. 3 Pilot

Loading...

Loading...