The steering knuckleis attachedto the front axle housing

by the king pins which are carried in taper roller bearings.

The bearing preload of the king pins is adjusted with

shims at the upper pin.

The differential is provided with an automatic differential

brake. The friction discs are fitted between the differential

side gears and the differential casing.

Position of pinion shaft, tooth backlash and differential

and pinion bearing preload are adjusted with shims.

965

Model Code Page

64. Powered front axle

1. 1. 1995

6000--8750 640 5

8. 11. 1990

Powered front axle, description

Po wered front axle on 6100---8100 tractors is the same Sige---

axle as on Valmet ---05 series.

The powered front axle is attached to the front end of the trac-

tor by two bearing brackets. There is a small clearance be-

tween the axle housing and central pivot bearing brackets.

This clearance can be adjusted with shims.

The power is transmitted from the gearbox to the pinion shaft

by the propeller shaft. From the pinion shaft, power is trans-

mitted through the differential to the drive shafts and through

the double universal joints to the hub reduction gears and the

front wheels

The drive shafts are carried in bearing bushings in the axle

housing and in ball bearing in the swivel housings.

In each hub gear the planetary pinions (3 off) are carried in

roller bearings in the retainer. The ring gear is bolted to the

steering knuckle.

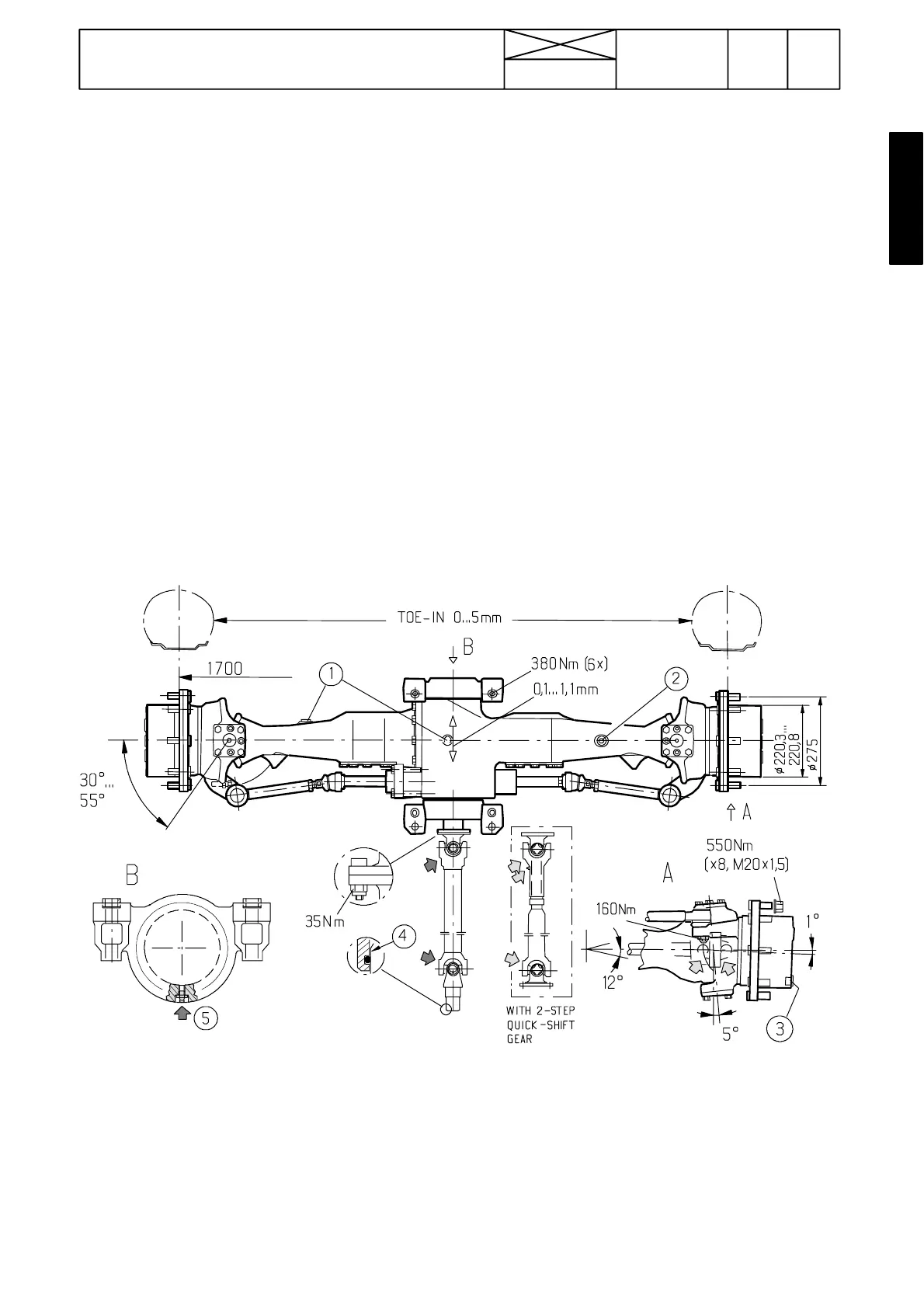

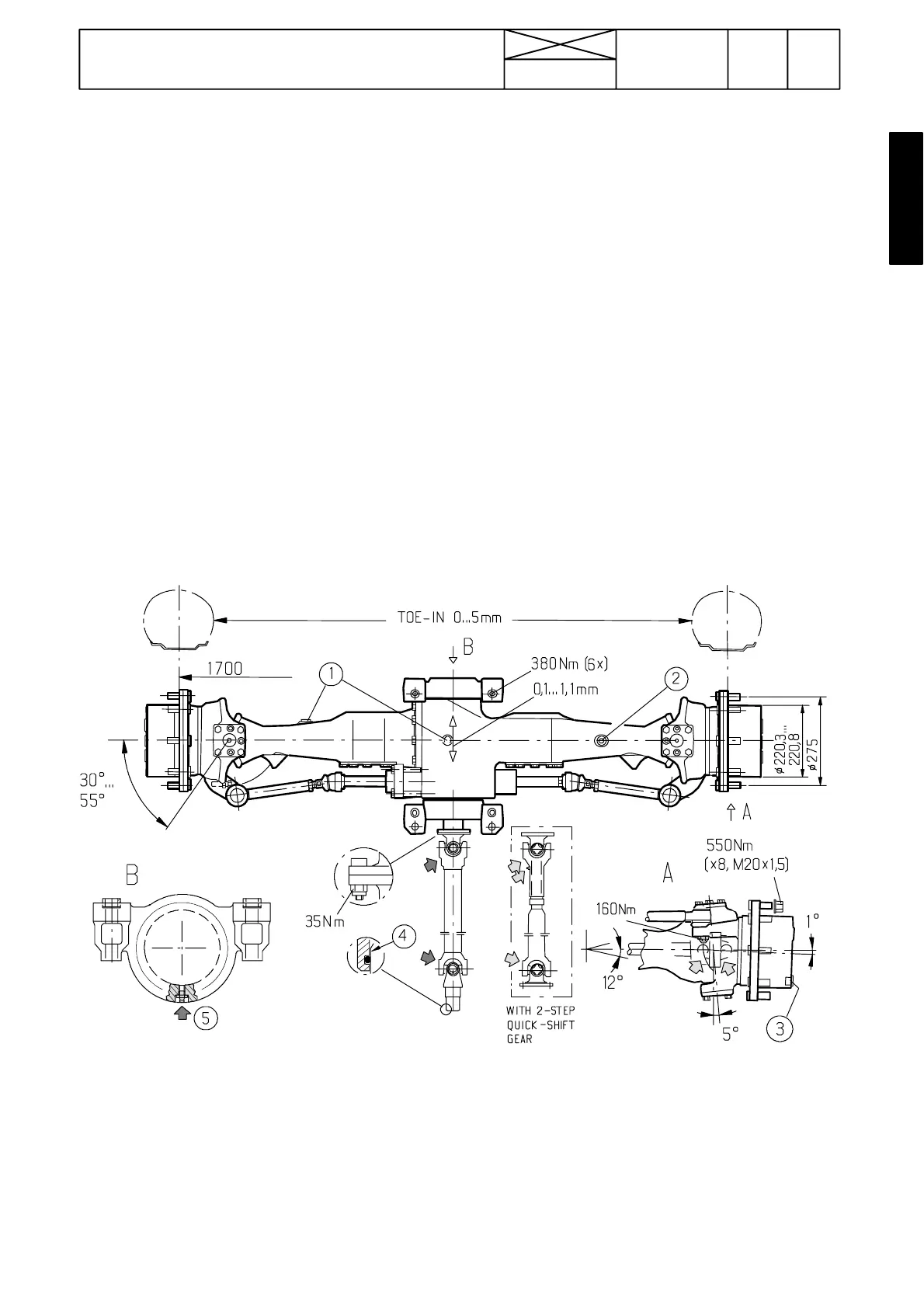

Figure 2. Sige front axle

1. Plug for checking and raining oil in differential housing

2. Oil filling plug for differential housing

3. Oil filling and draining plug for hub

Note! Oil levels in the axle should be checked every 500 running hours. Oil should be changed yearly/every 1000 running hours.

Central pivot bearing bracket nipples (B) must be greased at every 50 running hours, other nipples at every 250 running hours.

4. Pressure resistat grease on splines in conne ction with repairs

5. Earlier two grease nipples, later one grease nipple.

Loading...

Loading...