204 Heavy Duty Combination Brake Lathe

OPERATION (continued)

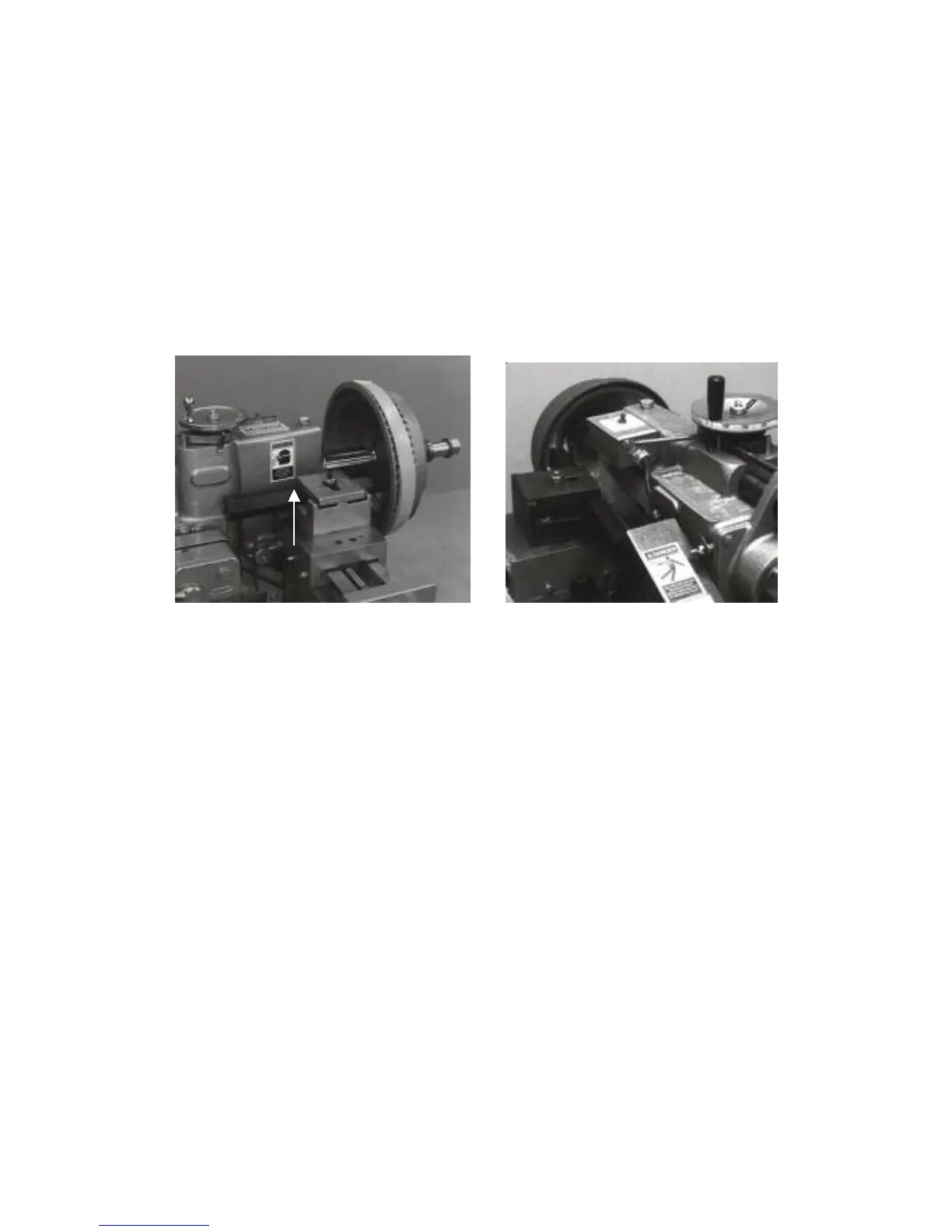

10.Wrap and secure the drum silencer band tightly around the drum (Figure 14).

11.Turn the cross feed handwheel and the spindle feed handwheel to their maximum

clockwise position. Then back off the cross feed handwheel 2 turns and the spindle

feed handwheel 4 turns.

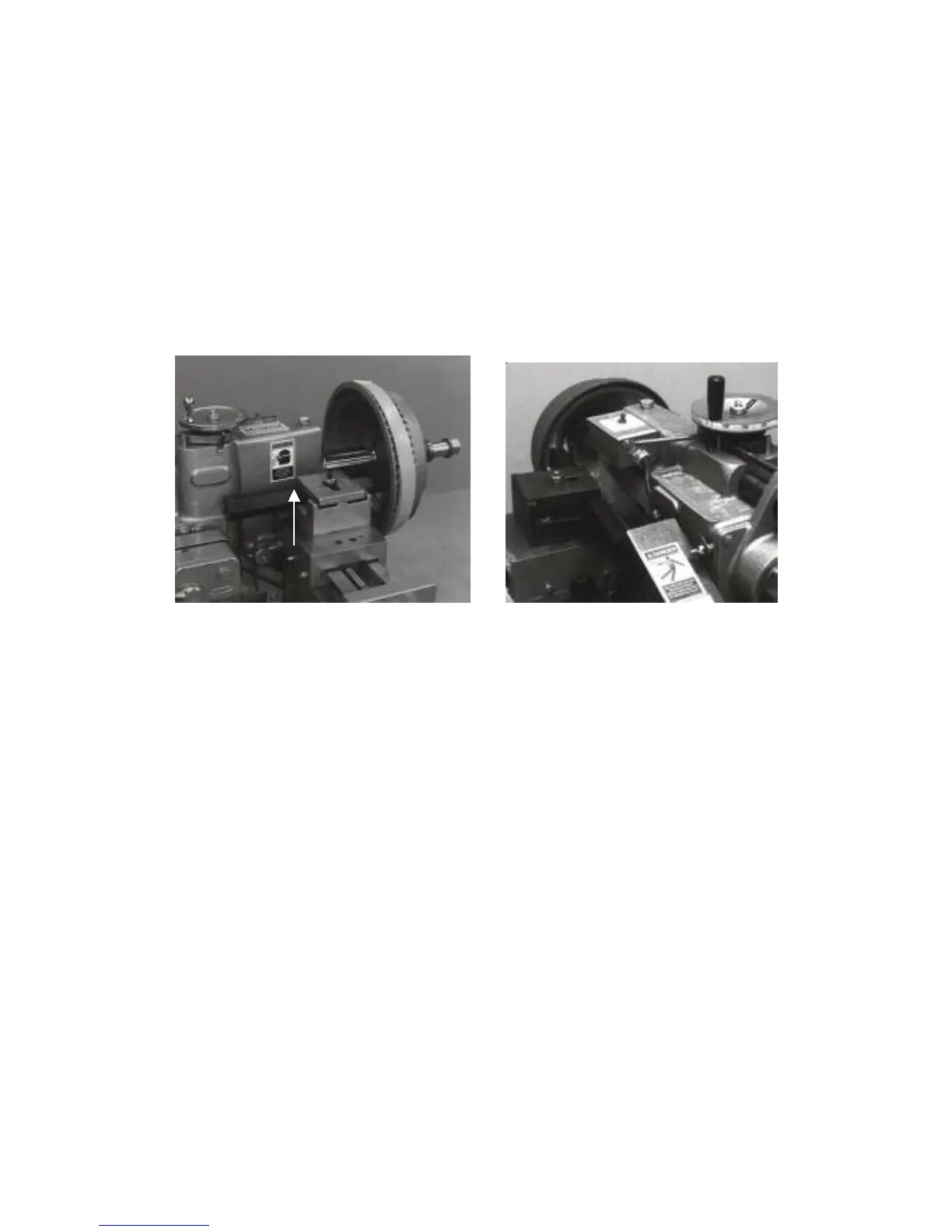

12.Position the tool bar by loosening the tool bar clamp nut (Figure 14 & 15) and sliding

the tool bar inward toward the drum until the tool bit is close to the surface that is

going to be machined. The entire tool bar may also be swiveled to achieve the best

cutting position.

Figure 14 Figure 15

13.Turn the drum by hand to be sure that it runs true. Turn the lathe on and advance

the tool bit manually until it just contacts the drum surface and makes a scratch cut.

Back the tool bit off, stop the lathe. Loosen the arbor nut and rotate the drum one-

half turn. Retighten the nut, turn the lathe on and make a second scratch cut, stop

the lathe. If the first and second scratch cuts are opposite one another (180° apart)

remove the drum from the arbor. Check the mounting adapters and the arbor for

nicks, burrs or chips. Clean if necessary. If the scratches are side by side, proceed

turning the drum.

14.Turn the spindle feed handwheel until the deepest worn groove of the drum is

opposite the point of the tool bit. Advance the tool bit into the bottom of the groove

by rotating the tool bit into the bottom of the groove by rotating the cross feed

handwheel counter-clockwise.

15.The depth of cut dial will show the approximate reconditioned diameter of the drum.

Make sure that the resurfaced drum will be within the limits cast into the drum.

16. Roughing cuts should be no deeper than .010” (.25mm): finish cuts no shallower

than .002” (.05mm). Usually no more than 2 cuts are required to resurface a drum.

With the lathe running, set the depth of cut, dial to the desired depth and lock the

cross slide by tightening the cross slide locking knob.

Van Norman 16. 888-855-1789

Loading...

Loading...