DESCRIPTION Section 2 - Pg 04

2.4 Compressor Discharge System, Functional Description - Continued

The sump is ASME code rated at 175 psig working pressure. A minimum

pressure/orifice valve, located downstream from the separator, helps assure a minimum

receiver pressure of 65 psig during all conditions. This pressure is necessary for proper

air/fluid separation and proper fluid circulation.

An optional check valve at the outlet of the receiver can be installed to prevent

compressed air in the service line from bleeding back into the receiver on shutdown when

the compressor is being run in parallel with other compressors tied to a large air system.

A pressure relief valve (located on the wet side of the separator) is set to open if the sump

pressure exceeds 175 psig. A temperature switch will shut down the compressor if the

discharge temperature reaches 240°F.

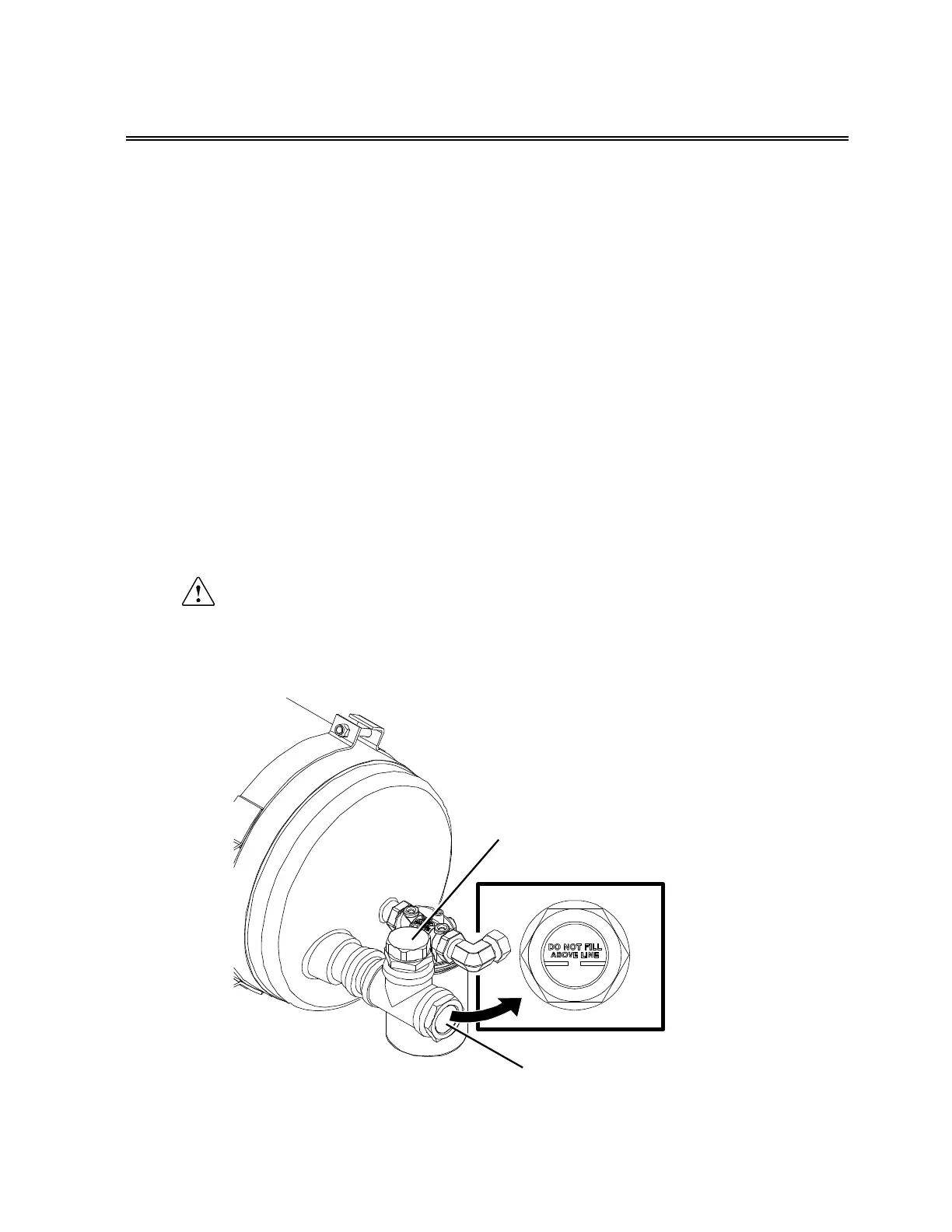

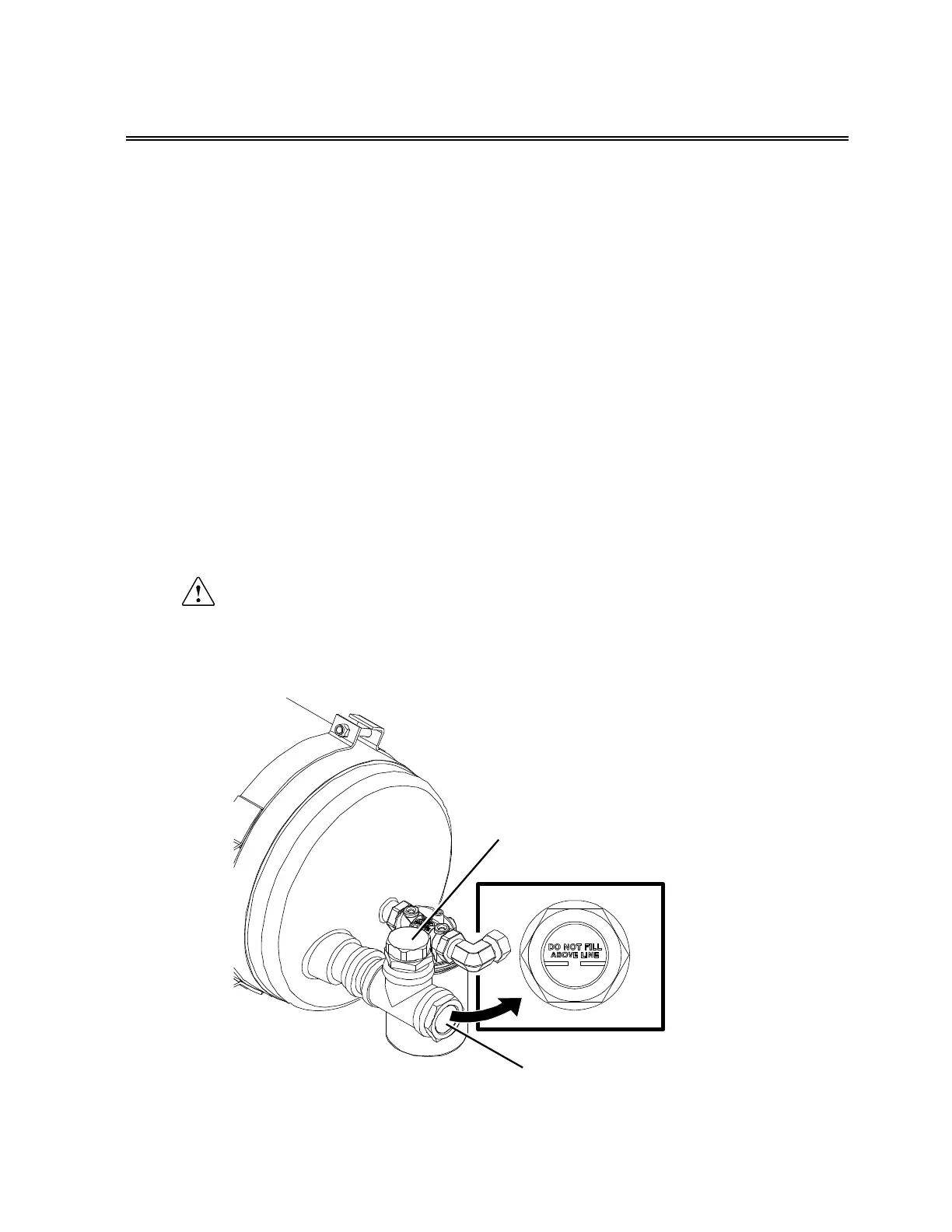

Fluid is added to the sump via a capped fluid fill port (Figure 2-2). A glass fluid level

gauge enables the operator to visually monitor the sump fluid level.

WARNING: DO NOT remove caps, plugs, and/or other components when

compressor is running or pressurized. Stop compressor and relieve all internal pressure

before doing so.

OIL FILL PORT

OIL FILL SIGH T GLASS

Figure 2-2: Oil Fill Port and Sight Glass

Loading...

Loading...