OPERATION Section 4 - Pg 01

SECTION 4:

OPERATION

4.1 General

While Vanair

®

has built into this compressor a comprehensive array of controls and

indicators to assure you that it is operating properly, you will want to recognize and

interpret the readings which will call for service or indicate the beginning of a

malfunction. Before starting your Vanair compressor, read this section thoroughly and

familiarize yourself with the controls and indicators - their purpose, location and use.

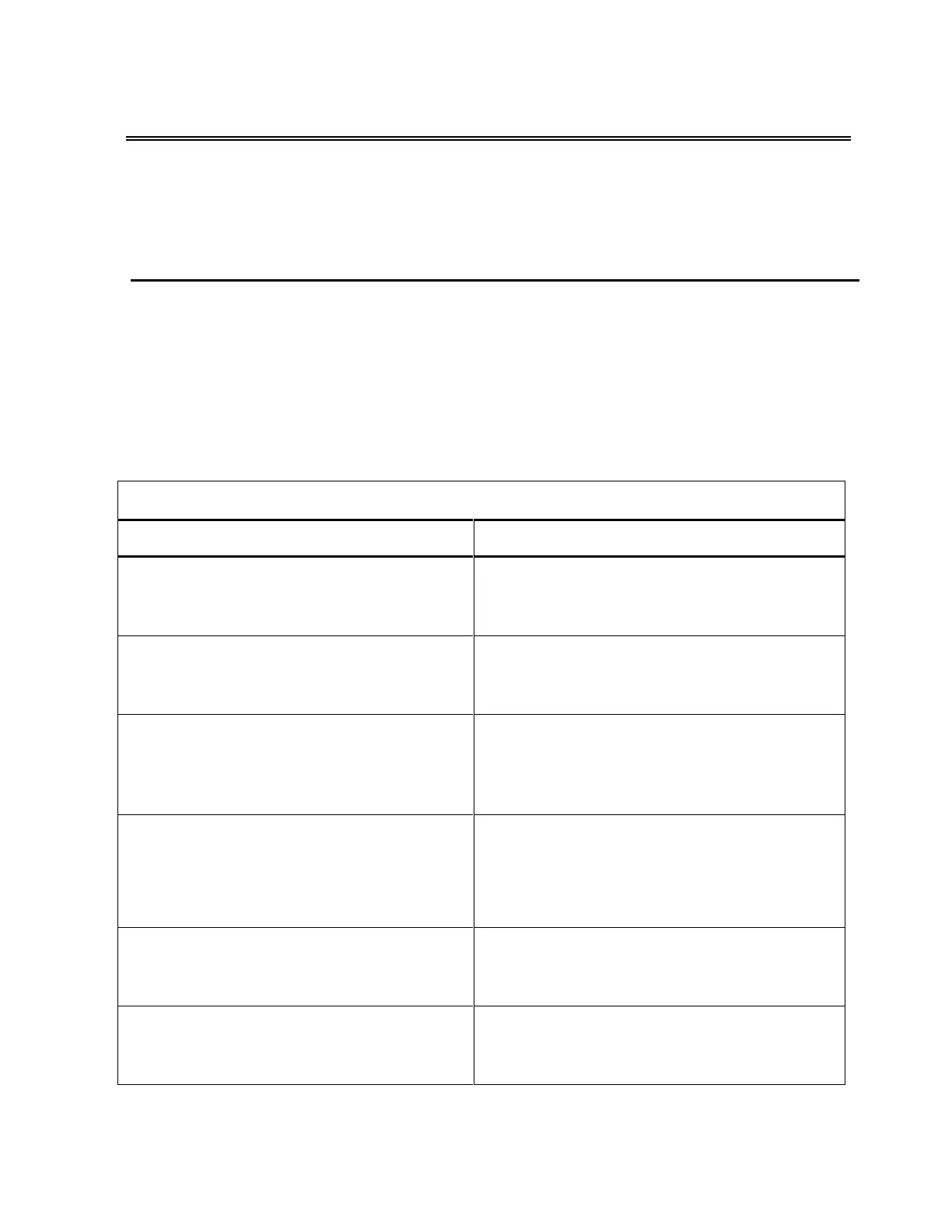

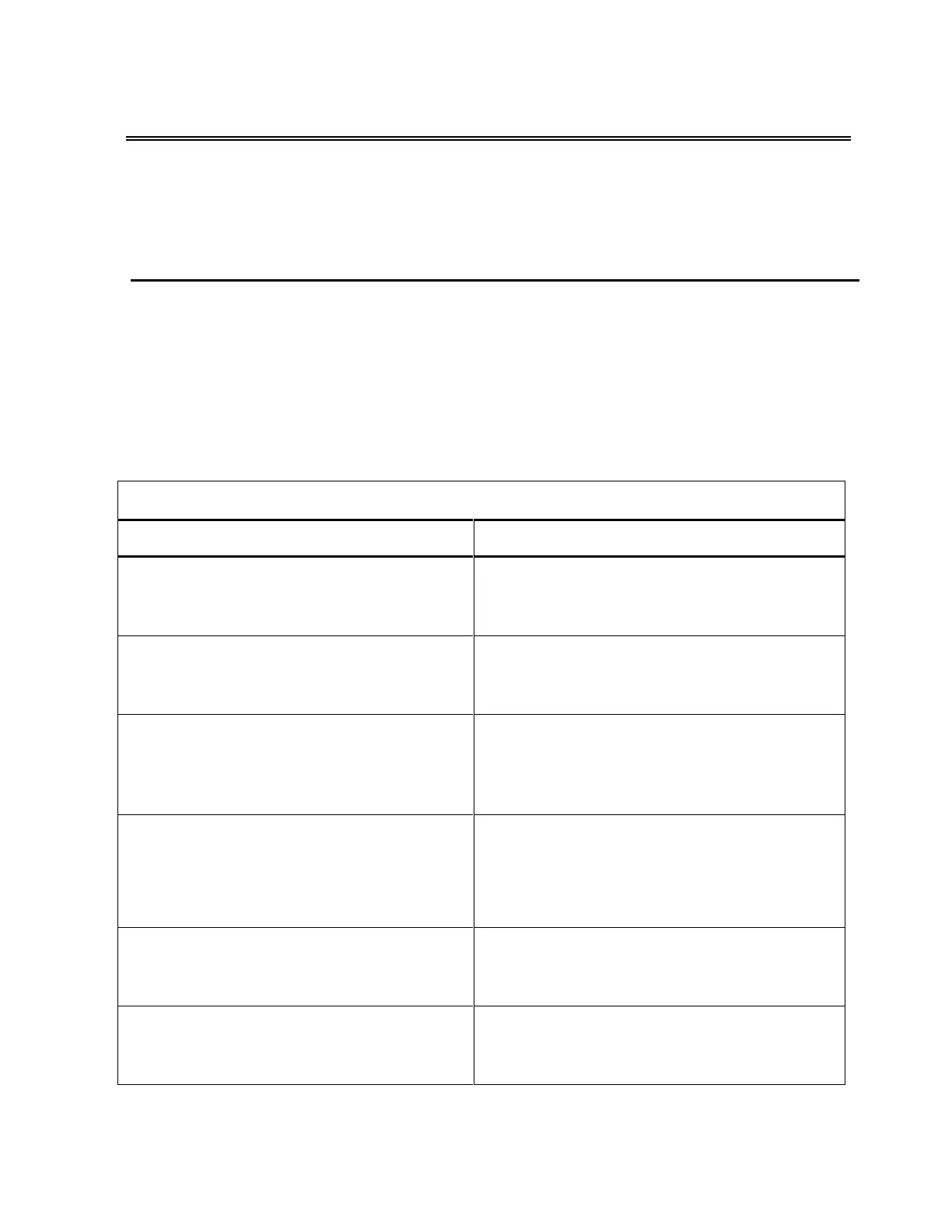

Continually monitors the pressure inside the

receiver tank at various load and unload

conditions.

Indicates the cumulated hours of operation.

Useful for planning and logging service

schedules.

COMPRESSOR DISCHARGE

TEMPERATURE GAUGE

Monitors the temperature of the air/fluid

mixture leaving the compressor unit. The

normal reading should be approximate 180° to

210°F.

Monitors the fluid level in the sump. Proper

level is always visible in the sight glass.

Check the level when the compressor is shut

down.

COMPRESSOR DISCHARGE

TEMPERATURE SWITCH

Opens the electrical circuit to shut down the

compressor when the discharge temperature

reaches 240°F.

Regulates the amount of air allowed to enter

the air end. This regulation is determined by

the amount of air being used at the service line.

Loading...

Loading...