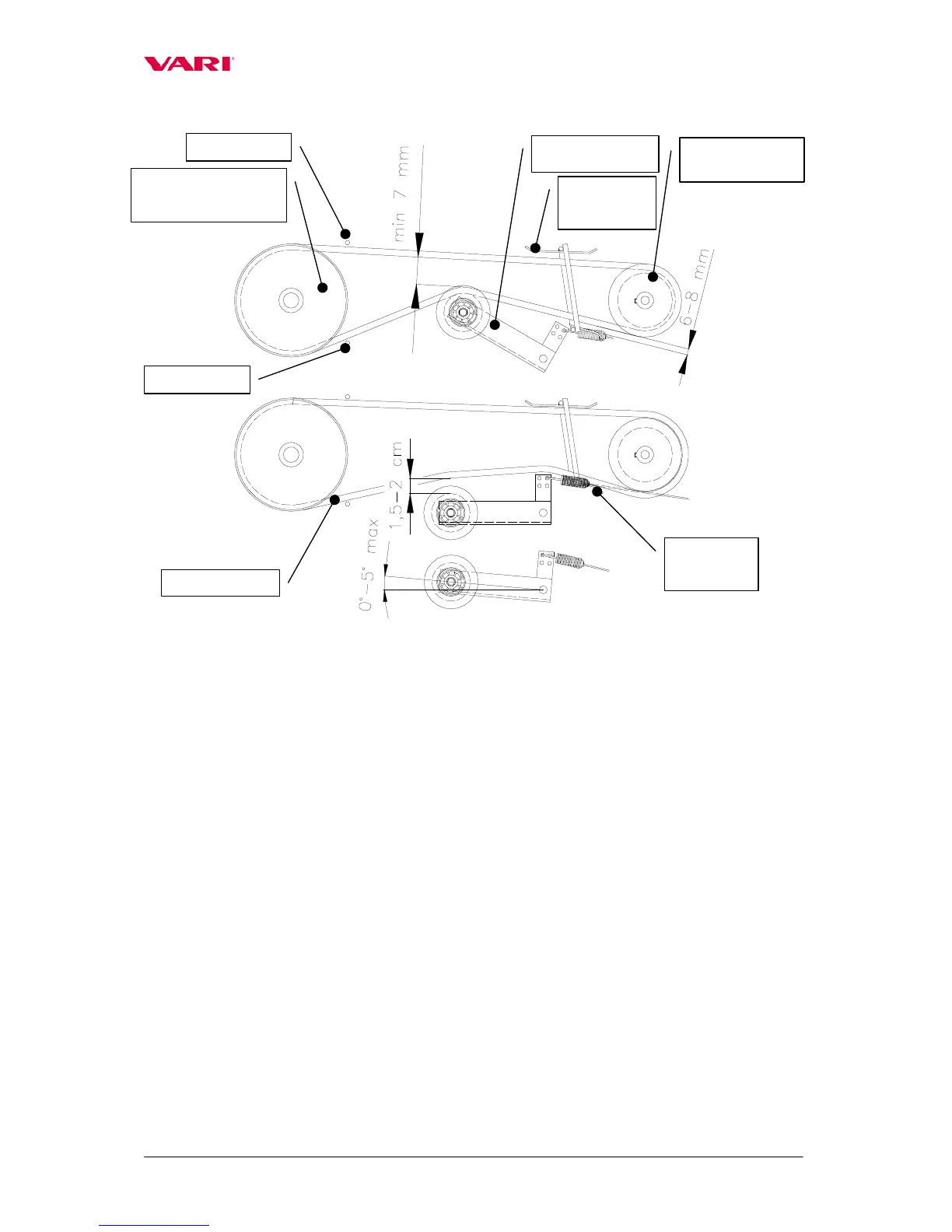

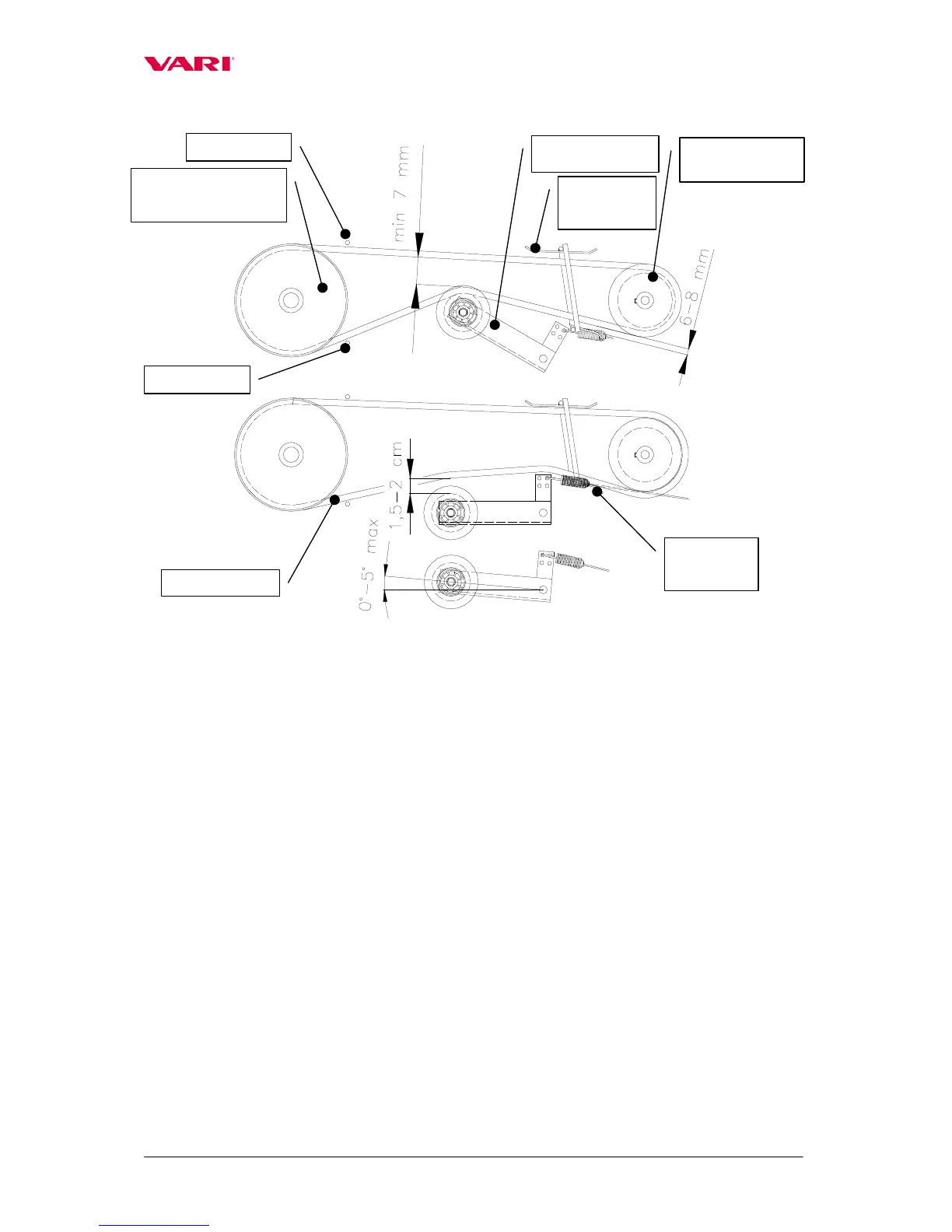

6.5 Adjusting the litz wires of pulley, brake and wheel drive clutch.

In order to guarantee low operating forces on levers which control the drive switching, it

is advisable to lubricate the cables in Bowdens at least 2x during the season with some of oils

available in atomiser (e.g. SILKAL, MD Spray, WD40). Correct functioning of the machine

also requires correct adjustment of drive controls.

Litz wire in the brake Bowden must always exhibit a slight slackness (with the lever of

the cutting disk drive clutch and brake released) so that the brake performance is sufficient.

In order to achieve clearance of the brake litz wire in the Bowden, adjustment bolts have to

be screwed into the chassis or handlebars cross-beam at the adjustment.

Litz wires in the pulley Bowden and in the Bowden of wheel drive clutch must be

without slackness, slightly tense. In order to make the litz wires tense, adjustment bolts have

to be screwed out of the chassis or handlebars cross-beam.

Safety nuts in all adjustment bolts should be tightened by using two flat wrenches No. 10

or 9. If there is no more step to be used in the adjustment bolt, it is possible to displace the

hook on the litz wire into another hole in the sheet-metal lever on handlebars (or on the wheel

drive clutch lever on the gearbox and on the arm of the tightening pulley – see Figs. 7 and 8)

so that the initial tension of the litz wires can be again regulated by the adjustment bolt.

Loading...

Loading...