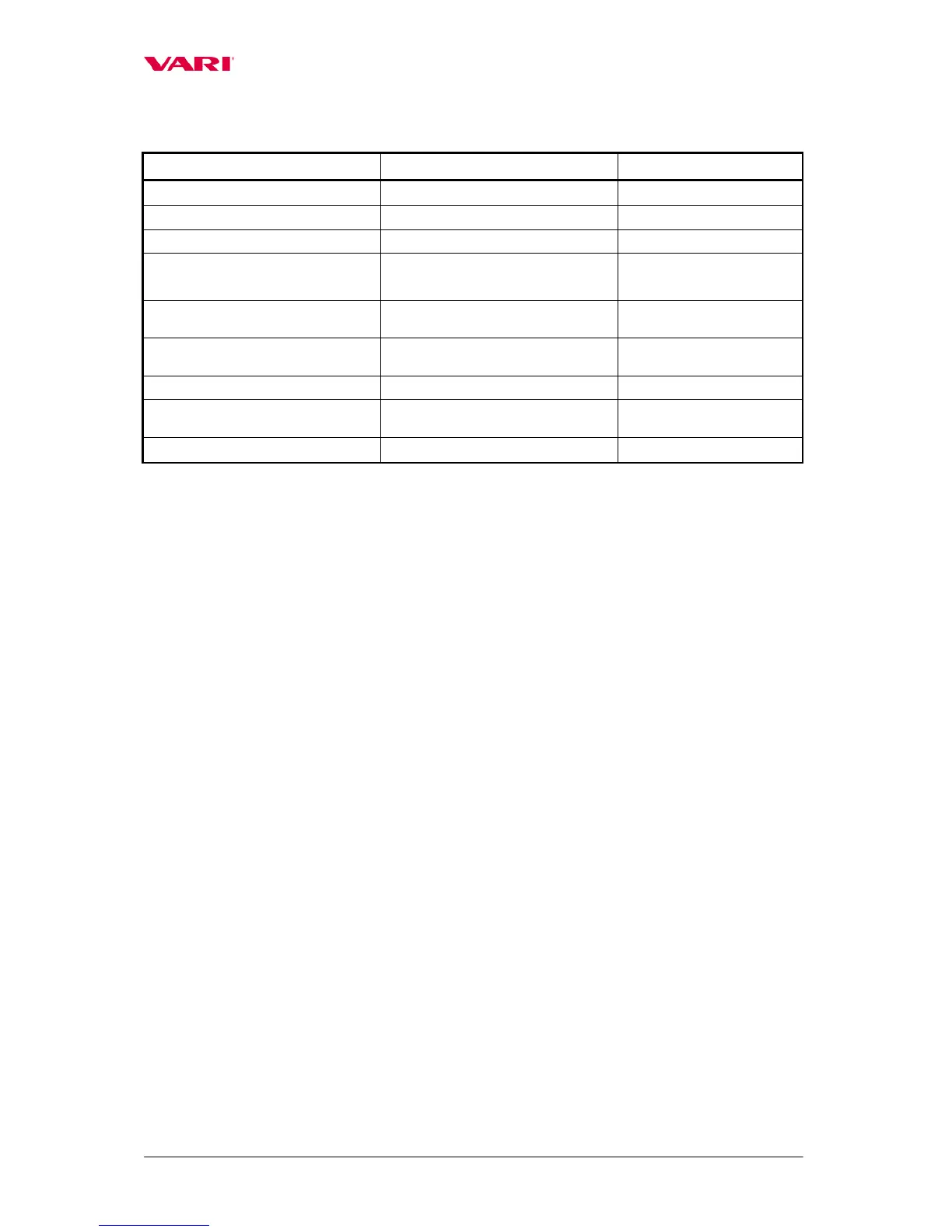

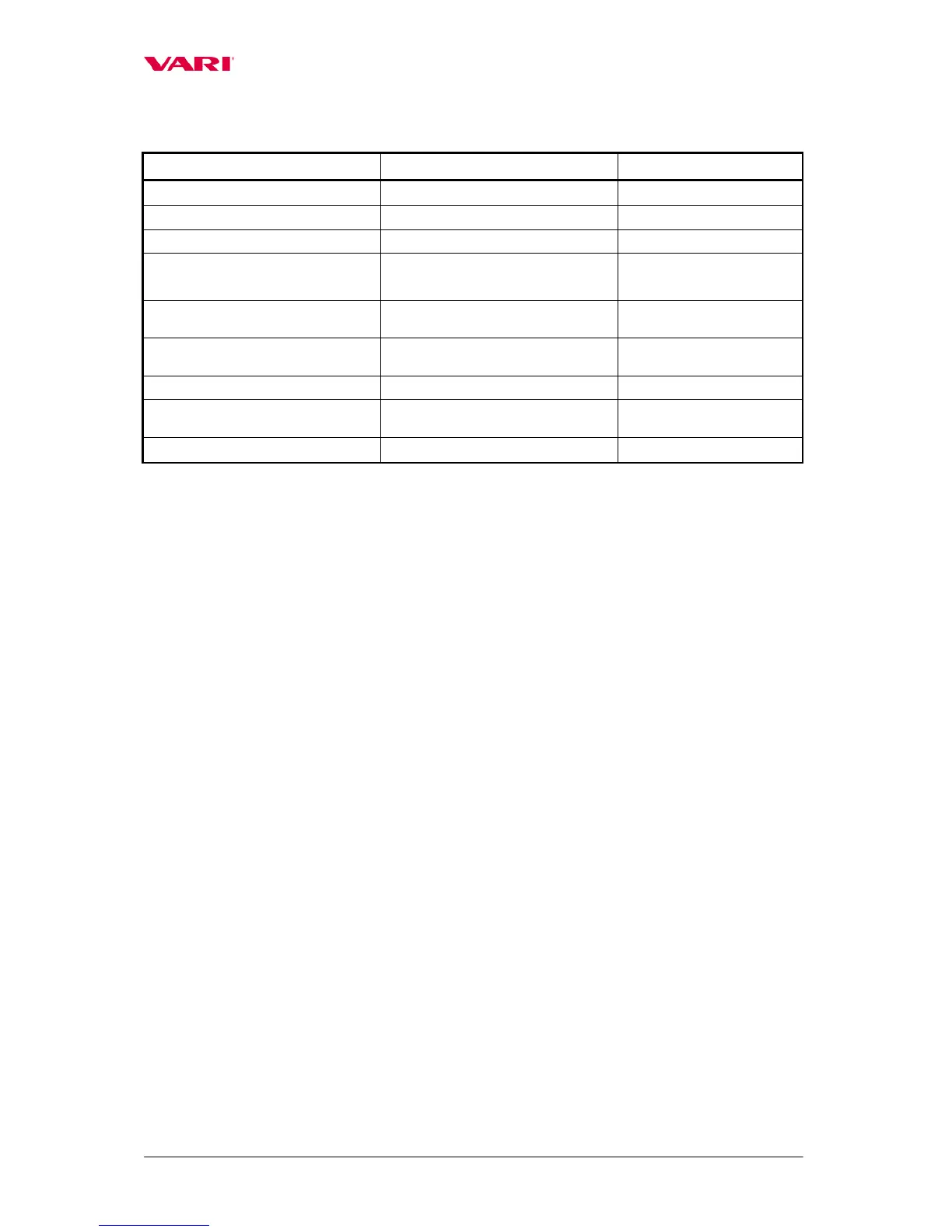

Engine oil volume check prior to each machine use **

Engine air filter check prior to each machine use check

Check of blades for fastening and

intectness

prior to each machine use, *** check

Check of upper and lower disks for

their intactness and fastening

prior to each machine use, *** check

Check of V-belt tension

after 2 hrs., then each 20 hrs.

or as required

check

Check of V-belt condition as required check, ****

Cleaning of wheel hubs and grease

exchange

-

* - First exchange after 5 hours, than after 100 to 130 hours (in dependence on oil grade)

** - Oil replacement intervals see Operating manual for engine

*** - In case of damage (even during cutting) – crack, bend, breakage, etc. – repair

required without a delay!

**** - or replacement after about 100 hours.

6.8 Washing and cleaning the machine.

Cleaning and washing the machine, proceed to observe valid regulations and

legislation on the protection of water courses and other water resources against

pollution or contamination with chemical substances.

Never wash the engine with a stream of water! Electric equipment might fail when

starting the engine.

All dirt, debris and plant residues should be removed from the machine after the end of

the season. Check the intactness of working blades, sharpen cutting edges (or replace the

blades if necessary) and conserve the blades with conservation oil. Travel wheels should be

dismounted from the axle once in a season, cleaned and the hubs inside filled with a new

filling of plastic lubricant.

The engine must be switched off and the cable termination to the spark plug

disconnected!

Procedure of wheel disassembly, lubrication and re-assembly:

a) Underlay the machine so that the wheels can freely turn. The machine must be secured

against spontaneous motion.

b) Take out the split pin and screw the slotted nut out by using spanner No. 24. Remove the

wheel from the axis.

c) Clean the wheel hub inside, wheel hub flange with balls and the free wheel from dirt and

old grease.

Loading...

Loading...