F-550

2.5.5.2 Replacing the V-belt

Always replace the V-belt

70

with a new one whenever the belt shows signs of cracking or tearing and whenever the belt is so worn that it

can no longer be tightened using tensioners. The exact procedure for changing the belt is not included here because it would exceed the

scope of this manual. When replacing, follow the instructions given in

Pic.9

,

10

and

16

. Ensure that the belt path around all leading

components is followed!

If you are not sufficiently technically competent, assign this task to a professional service centre.

2.5.5.3 Checking brake operation and adjusting the brake

Check the operation of the automatic brake after every 10 hours of use. You can perform regular checks when working. Whenever the

tool drive clutch lever is released, the automatic brake must stop the rotating work tool within 5 seconds.

Do not continue working unless you repair the defect on the automatic brake!

If you are not sufficiently technically competent, assign this task to a professional service centre.

If the brake does not stop the rotating tool within the specified time, the brake cable B on

Pic.11

,

12

and

14

must be adjusted. The

adjustment screw is attached on the brake cable ( B on

Pic.12

) to the frame, should be turned in the opposite direction of the arrow

(towards the frame) so that the axial clearance of the cable in the adjustment screw is 1 mm. Check the operation of the automatic brake.

If the screw B when fully tightened does not achieve sufficient braking, screw in the brake cable adjustment screw ( B on

Pic.14

) on the

handlebars so the cable axial clearance in the adjustment screw is 1 mm and subsequently recheck the operation of the automatic brake

71

.

If the brake fails to brake sufficiently even after adjustment, contact a professional service centre. Do not

continue operating the machine without a functional brake under any circumstances!

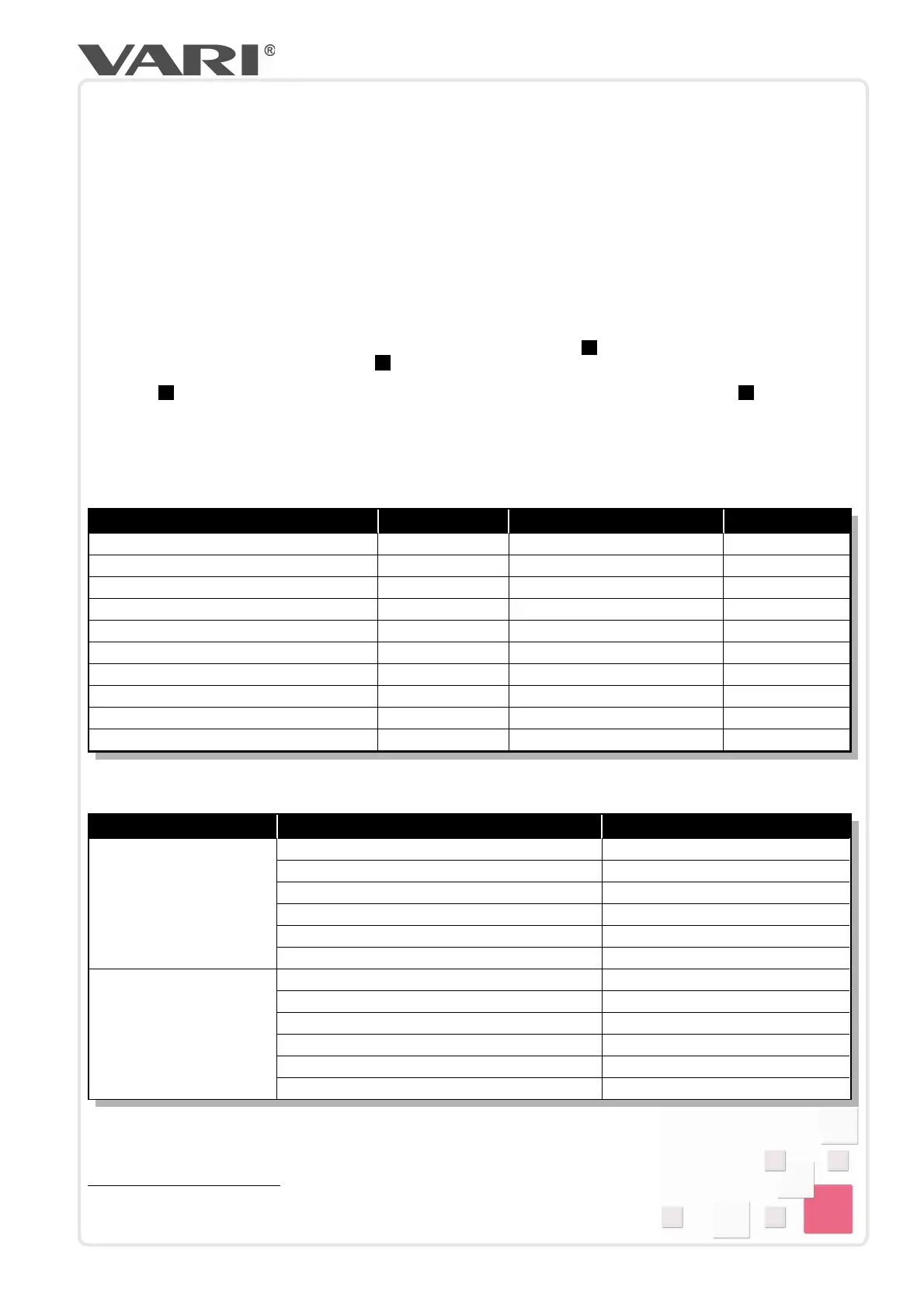

2.5.6 Servicing intervals

Activity Before use During the season Before storing

Check the engine oil level yes according to the engine operating manual yes

Clean the engine air filter check every 10 hrs

72

yes

Washing - 2x yes

Removing impurities and cut vegetation remnants - after each cutting yes

Sharpening the tool blades check as needed yes

Checking the blade mounting yes immediately replace if damaged yes

Checking the tightness of the work tool (blade) yes - yes

Check the tightness of screw connections yes every 5 hrs. yes

Lubrication inspect condition

Table 6

yes

Check V-belts - every 20 hrs. yes

Table 7: Service intervals

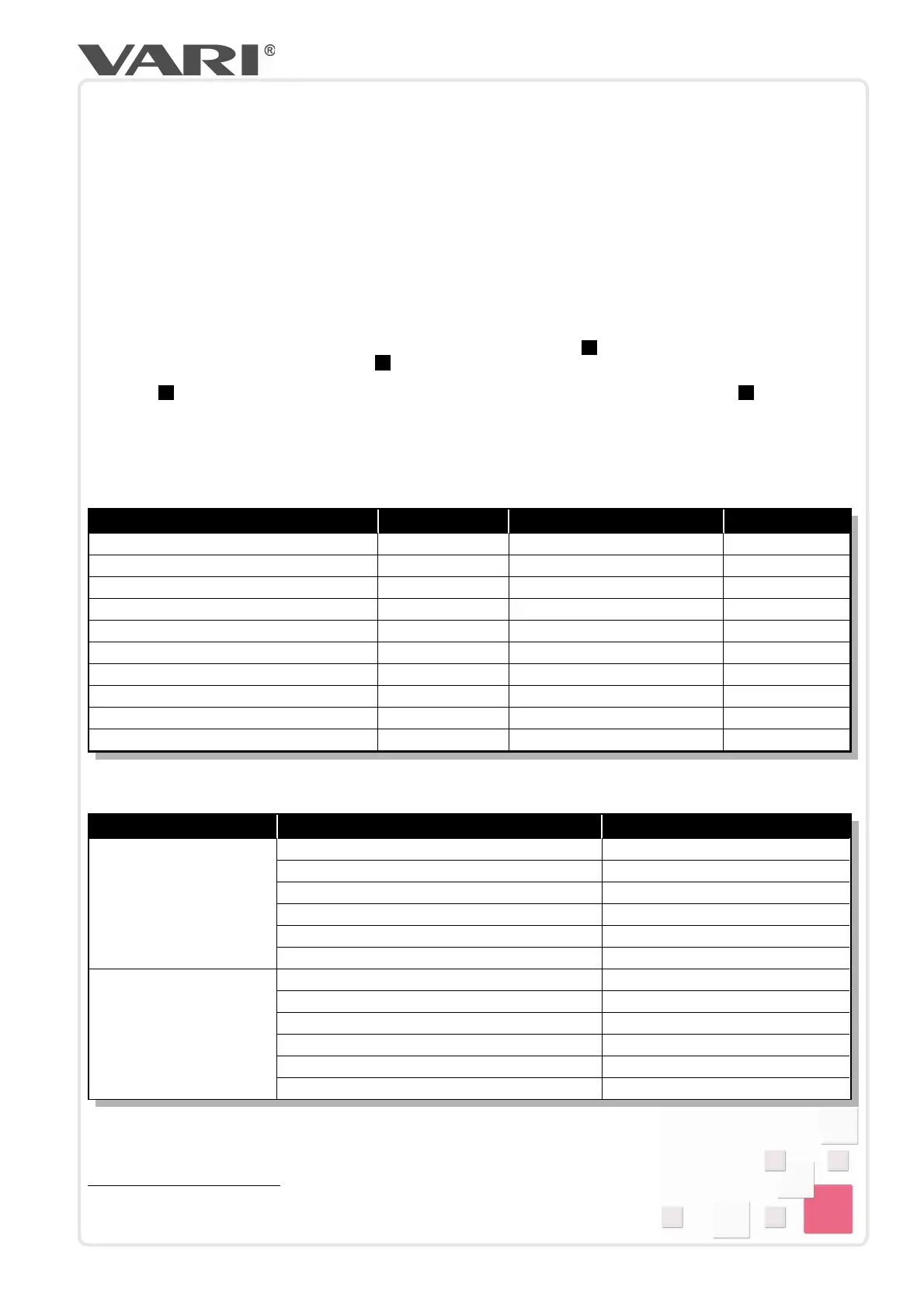

2.5.7 Problems and troubleshooting

Problem Cause Solution

The work tool does not turn Engine is not started Start the engine

The drive clutch lever is not depressed Depress the lever

The belt is loose Adjust the tensioner

Broken belt Replace the belt with a new one

Belt slid off Seat the belt

Other defect Contact the service centre

Machine does not move Engine is not started Start the engine

The drive clutch lever is not depressed Depress the lever

The belt is loose Adjust both tensioners

Broken belt Replace the belt with a new one

Belt slid off Seat the belt

Other defect Contact the service centre

70

Use exclusively genuine replacement parts. Proper gear function cannot be guaranteed when using V-belts from different manufacturers.

71

May be performed in the opposite way – first screw in (towards the handlebar traverse) Brake bowden cable screw on the handles so the axial clearance is 1 mm in the adjustment

screw.

72

In highly dusty conditions, check and clean every hour!

28

02/2013

Loading...

Loading...