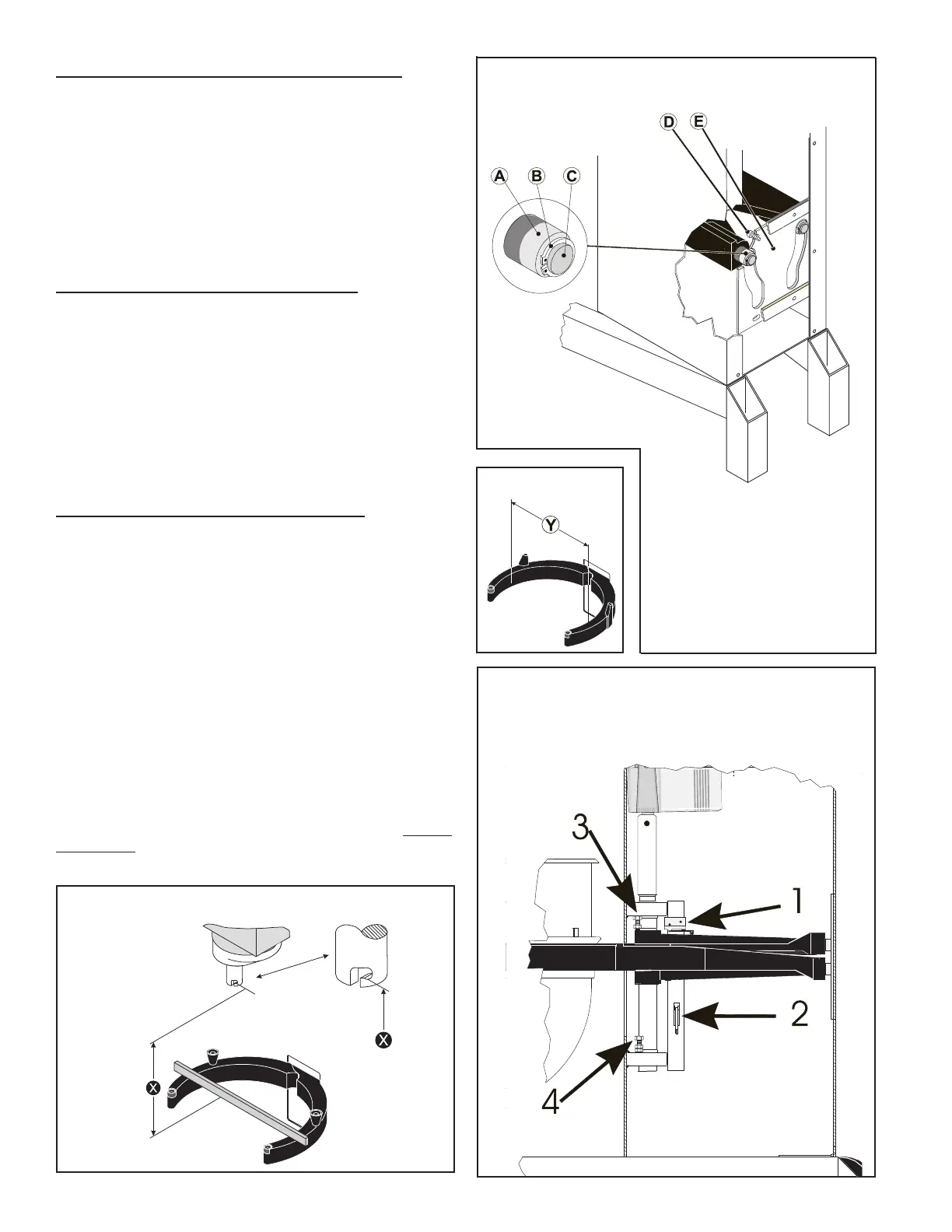

A

bowl, then raise the bowl arms up to normal working position.

With your hand turn the beater, and then measure the distance

between beater and bowl edge. By removing the rear covering,

the bowl arm guide plate is now accessible . Loosen the

screws and move the bowl arm guide plate in the required

direction. Again turn the beater and measure the distance

between beater and bowl. When the bowl has been centred,

fasten the bowl arm guide plate in the new position and screw

on the rear covering.

The bowl arms must be raised to normal working position. The

adjusting diameter shall be measured inside between the

bowl arms :

In case the bowl fastening is too loose, remove the lock ring

and draw the bearing from the shaft . The bearing

should be turned 180

and be mounted on the shaft again.

It might be necessary to turn both bearings. At last check the

bowl centering and if necessary, adjust.

The distance is measured from the bottom side of the

bayonet hole to the surface on the bowl arms on which the bowl

rests The bowl arms must be lifted to normal working

position.

"

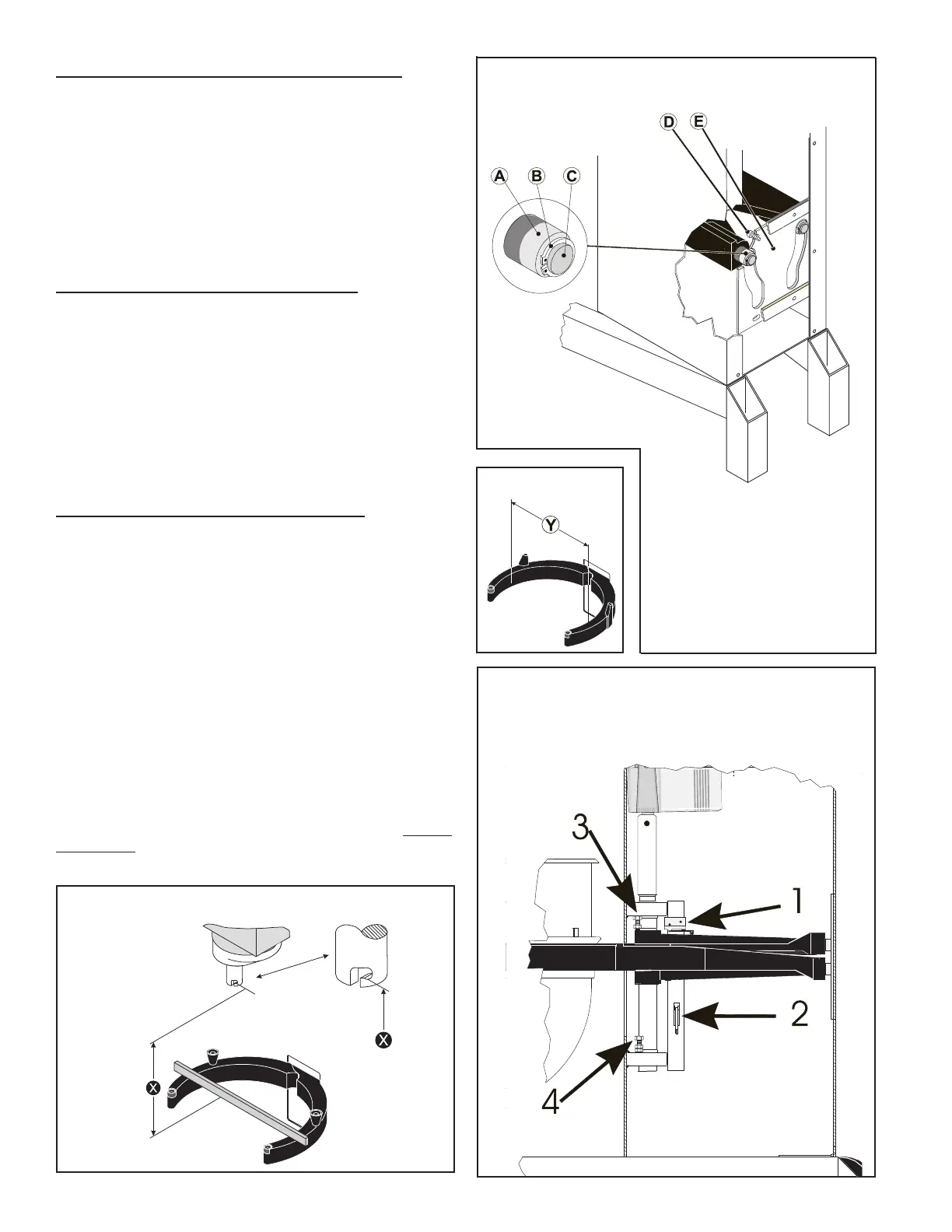

The upper and lower position of the bowl is determined by micro

switch and , . The two mechanical stops consist-

ing of the bolts and are adjusted so that they will be hit

approx. 0.04" after the micro switch, in case the micro switch

should fail.

The lower position is adjusted first; by sliding the en-

tire bracket assembly up or down on the slots on the

bracket (2). The upper position of the bowl arms is ad-

justed by adjusting the up position micro switch mount-

ing bracket (2) up or down; it is of utmost importance

that the stop screw (3) is re-adjusted afterwards.

Loading...

Loading...