This document provides installation, operating, and maintenance instructions for the VAT Series 150 low particle gate valve, equipped with a double-acting pneumatic actuator. This manual is essential reading for anyone involved with the product throughout its serviceable life, ensuring safe and correct handling.

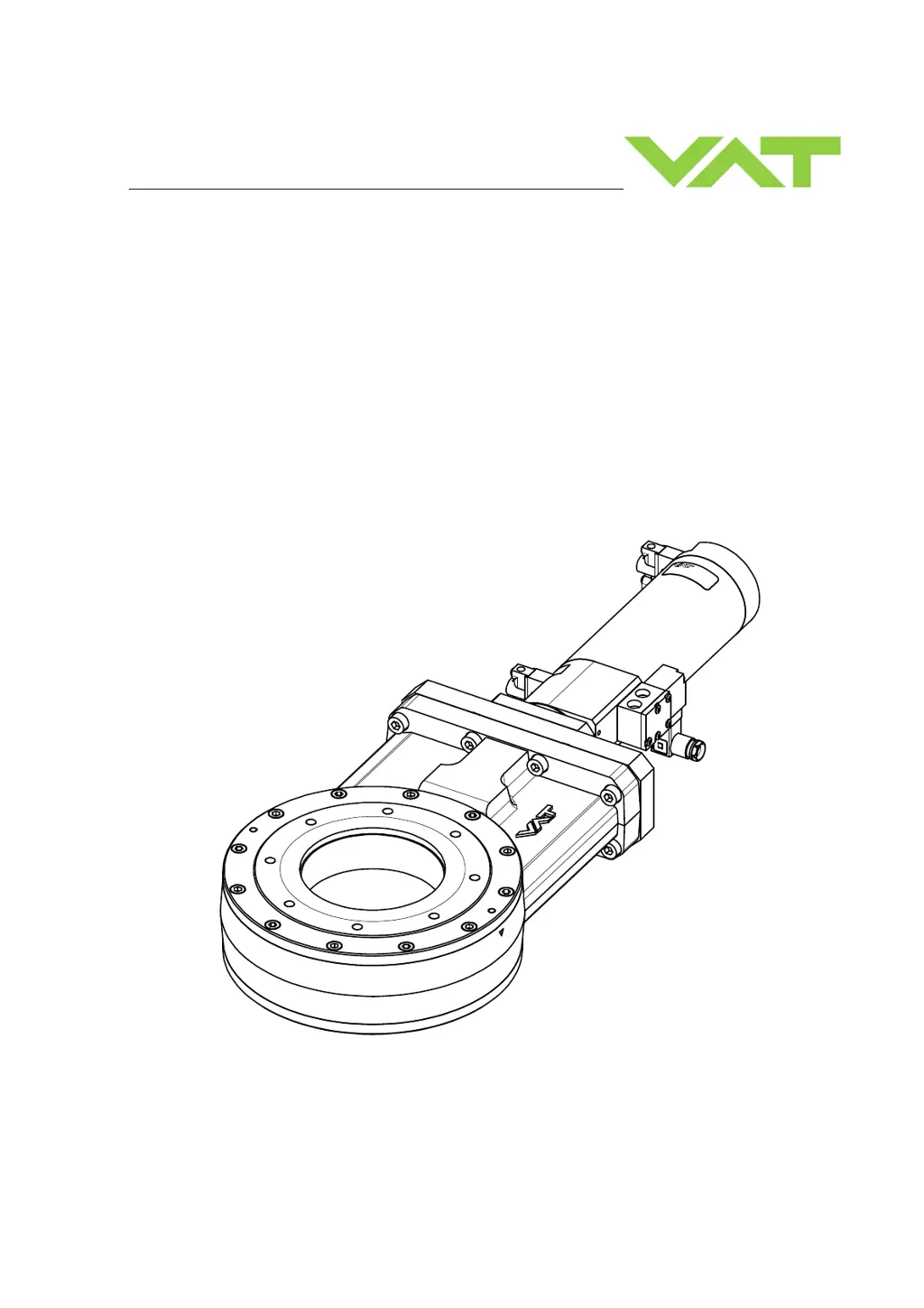

Function Description

The VAT Series 150 gate valve is designed for clean and dry vacuum applications. Its primary function is to open and close a vacuum chamber or system, thereby controlling the flow of gases. The valve utilizes MONOVAT sealing technology, which contributes to its low particle performance, crucial for sensitive vacuum environments. The valve's operation is facilitated by a compact double-acting pneumatic actuator, meaning it uses compressed air to both open and close the valve, providing precise and reliable control. Position indicators are integrated to show the current state of the valve (open or closed), and a solenoid valve controls the pneumatic actuation. The design incorporates a valve body, a MONOVAT gate, a vulcanized seal, a bonnet seal, and a shaft feedthrough, all working in concert to ensure effective sealing and operation within the vacuum system.

Usage Features

The valve is designed for straightforward operation, primarily controlled pneumatically. It opens and closes based on compressed air supply, which is managed by the solenoid valve. For safety and optimal performance, it is crucial to ensure the valve is completely mounted in the vacuum system before connecting compressed air or electrical power. The manual specifies admissible forces and bending moments to prevent deformation of the valve body and potential malfunction, emphasizing the need for suitable stress relief during installation. Electrical connections for the solenoid valve and position indicator must be supplied with the correct voltage to avoid damage.

In situations of power failure, the valve offers a manual emergency operation feature, provided compressed air is still available. For standard solenoid valves, a push-button allows for manual opening and closing. For solenoid valves with a lockable emergency operation option, a push-and-rotate mechanism enables manual actuation and locking in the open or closed position. This manual override capability ensures system control even under unexpected conditions. The valve's behavior in case of compressed air pressure drop or power failure is detailed in the product data sheet, allowing users to understand its fail-safe characteristics.

Maintenance Features

Maintenance of the VAT Series 150 valve is designed to be manageable, with clear guidelines for ensuring its longevity and performance. Under clean operating conditions, the valve requires maintenance only after a specified number of cycles, as detailed in the product data sheet. Key maintenance tasks include the replacement of the gate and bonnet seal. The manual provides a step-by-step procedure for this, emphasizing the use of appropriate tools and adherence to specified tightening torques to prevent damage.

Before any maintenance work, it is imperative to disconnect both the compressed air supply and electrical power supply to prevent serious injury from movable parts or electric shock. The process involves venting chambers to atmospheric pressure, opening the valve, and then carefully dismounting components such as screws, the upper valve body, and the gate. Cleanroom gloves are recommended during handling to prevent contamination of sealing surfaces. The manual also provides specific tightening torque specifications for bonnet screws and gate fixation screws, ensuring components are reassembled correctly and securely. An O-ring removal tool is listed as a required item for seal replacement, highlighting the need for specialized tools to avoid damaging delicate sealing surfaces.

Troubleshooting guidance is provided to address common issues such as the valve not closing/opening, leaks at the gate, or leaks at the body. This section outlines checks for air pressure, operating pressure, voltage at the solenoid valve, and the condition of seals, along with corresponding actions like connecting compressed air, adjusting pressure, or replacing seals. For more complex issues or general overhauls, users are directed to contact VAT service centers. The manual also includes instructions for dismounting and storage, emphasizing cleaning, covering openings with protective foil, and using original packaging to prevent damage. When returning products to VAT, specific forms for chemical or radioactive contamination must be completed, ensuring safe and compliant handling.