Installation, Operating &

Maintenance Instructions

984360EC.DOCX Edition 2022-08-12

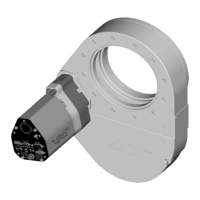

Butterfly Pressure Control Valve

with RS232 interface

Series 613

DN 25-320 mm (I.D. 1“ - 12")

This manual is valid for the valve ordering number(s):

613 . . - . .GH - . . . . (2 sensor inputs / analog outputs)

613 . . - . .AH - . . . . (2 sensor inputs / analog outputs / ±15V SPS)

613 . . - . .HH - . . . . (2 sensor inputs / analog outputs / PFO)

613 . . - . .CH - . . . . (2 sensor inputs / analog outputs / ±15V SPS / PFO)

SPS = Sensor Power Supply PFO = Power Failure Option

configured with firmware : F01.0C.28.xx

Sample picture