Installation, Operating & Maintenance Instructions

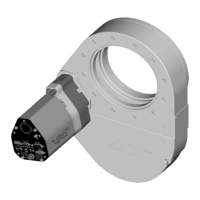

Series 615 DN 40 (I.D. 1½”), DeviceNet

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel +41 81 771 61 61 Fax +41 81 771 48 30 CH@vatvalve.com www.vatvalve.com

Butterfly control & isolation valve

with extended control range

with DeviceNet interface

This manual is valid for the valve ordering number(s):

61532-KEAQ-0001

configured with firmware 615P.1F.08 and 502689 (DeviceNet

®

)

The fabrication number is indicated on each product as per the label

below (or similar):

615 . . – . . . . – . . . . / . . . .

Explanation of symbols:

Read declaration carefully before you start any other

action!

Keep body parts and objects away from the valve

opening!

Hot surfaces; do not touch!

Loaded springs and/or air cushions are potential

hazards!

Disconnect electrical power and compressed air lines.

Do not touch parts under voltage!

Read these «Installation, Operating & Maintenance Instructions» and the enclosed «General

Safety Instructions» carefully before you start any other action!