0706

2.1 Brief Introduction

SummarySummary

Newyork2500 welding machines adopts the latest pulse width modulation (PWM)

technology and insulated gate bipolar transistor (IGBT) power module, which can change

work frequency to medium frequency so as to replace the traditional hulking ork frequency

transformer with the cabinet medium frequency transformer. Thus, its characterized with

portable, small size, light weight, low consumption and etc.

Newyork2500 machines Characteristics::

◆MCU control system, responds immediately to any changes.

◆High frequency and high voltage for arc igniting to ensure the success ratio of

igniting arc, the reverse polarity ignition ensures good ignition behavior in TIG-AC

welding.

◆Avoid AC arc-break with special means, even if arc-break occurs the HF will keep

the arc stable.

◆Pedal control the welding current.

◆D o u b l e p u r p o s es: A C i n v e r ter T I G a n d D C i n v e r t er T I G / M M A, E x c e l lent

performance on AL-alloy, carbon steel, stainless steel, titanium.

The parameters of on the front panel all can be adjusted continuously and steplessly,

such as start current, crater arc current, welding current, base current, duty ratio, upslope

igniting to ensure the success ratio of igniting arc.

◆In DC TIG without HFopertation, If the tungsten electrode touches the workpiece

when welding, the current will drop to short-circuit current to protect tungsten.

◆

occoured, the alarm lamp on the front panel will be on and the output current will

be cut off. It can self-protect and prolong the using life.

Intelligent protection: over-current, over-h eat, when the mentioned problems

time, downslope time, pre-gas, post-gas, pulse frequency, AC frequency, balance, hot start,

arc force and length etc. When welding, it takes high frequency and high voltage for arc

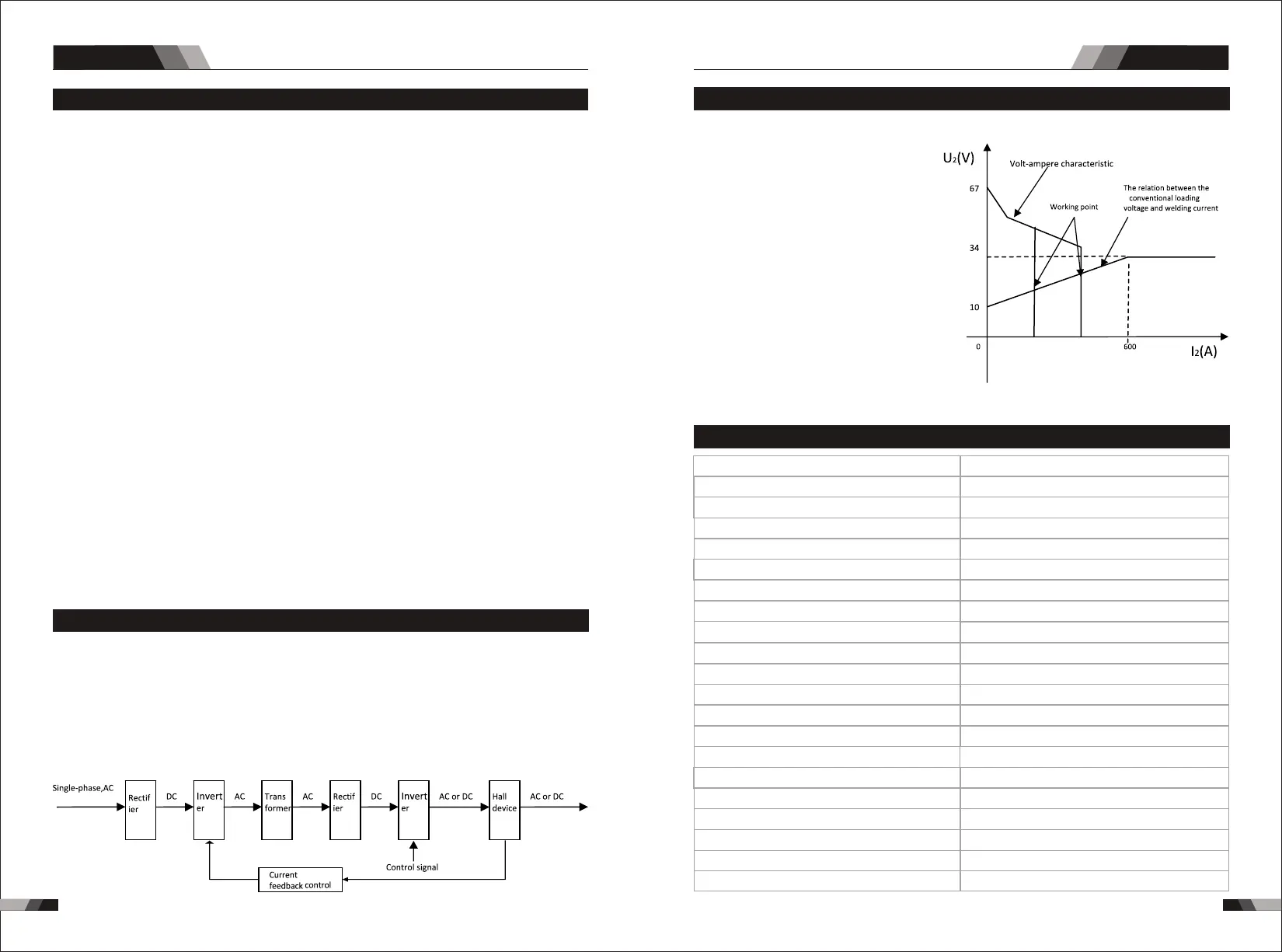

2.2 Working Principle

The working principle of Newyork2500 welding machines is shown as the following figure.

Single-phase 230V work frequency AC is rectified into DC (about 312 V), then is converted

to medium frequency AC (about 20-40KHz) by inverter device (IGBT module), after reducing

voltage by medium transformer (the main transformer) and rectifying by medium frequency

rectifier (fast recovery diodes), then is outputted DC or AC by selecting IGBT module. The

circuit adopts current feedback control technology to insure current output stably. Meanwhile,

the welding current parameter can be adjusted continuously and steplessly to meet with the

requirements of welding craft.

230V,50Hz

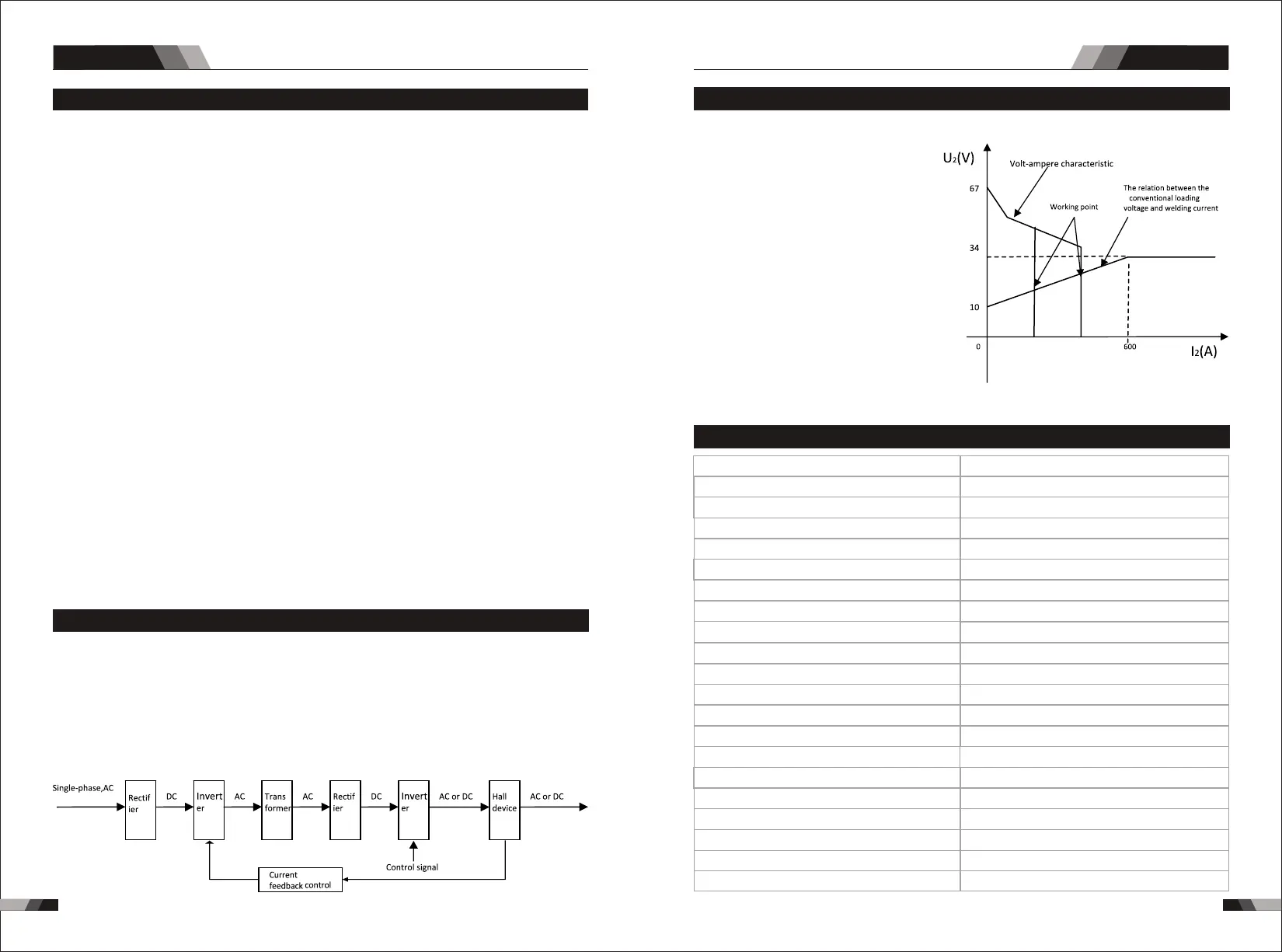

2.3 Volt- Ampere Characteristic

N e w y o r k 2 5 0 0 w e l d i n g m a c h i n e

h a s a n e x c e l l e n t v o l t - a m p e r e

c h a r a c t e r i s t i c , w h o s e g r a p h i s

s h o w n a s t h e f o l l o w i n g f i g u r e .

T h e r e l a t i o n b e t w e e n t h e c o n -

v e n t i o n a l r a t e d l o a d i n g v o l t a g e

U a n d t h e c o n v e n t i o n a l w e l d i n g

2

c u r r e n t I i s a s f o l l o w s :

2

When I ≤600A, U =10+0.04I (V);

2 2 2

When I ≤600A, U =20+0.04I (V);

2 2 2

When I ≤600A, U =80+0.4I (V);

2 2 2

When I >600A,U =34(V).

2 2

When I >600A,U =44(V).

2 2

TIG

MMA

CUT

2.4 Specifications

170A @ 25%, 26.8V / 85A @ 100%, 23.4V

200A @ 40%, 18V / 126A @ 100%, 15V

50A @ 40%, 100V / 25A @ 100%, 90V

11.5 kg

10 - 170A

10 - 200A

20 - 50A

15.4A

30.9A

10KVA

H360mmxW160mmxD380mm

Description

Weight

Power Source Dimensions

Cooling

Welder Type

European Standards

Number of Phases

Nominal Supply Voltage

Nominal Supply Frequency

Welding Current Range (MMA Mode)

Welding Current Range (TIG Mode)

Welding Current Range (CUT Mode)

Single Phase Generator Requirement

MMA Welding Output, 40ºC, 10 min.

TIG Welding Output, 40ºC, 10 min.

CUT Welding Output, 40ºC, 10 min.

Open circuit voltage (MMA/TIG)

Open circuit voltage(CUT)

Protection Class

Maximum Input Current

Effective Input Current

SIWM DIGITAL Newyork2500

Fan Cooled

EN 60974-1 / IEC 60974-1

1

230V +/- 15%

50/60Hz

60V DC

250V DC

IP23

Inverter Power Source

AC/DC PLASMA SERIES EQUIPMENTAC/DC PLASMA SERIES EQUIPMENT

Loading...

Loading...