12

13

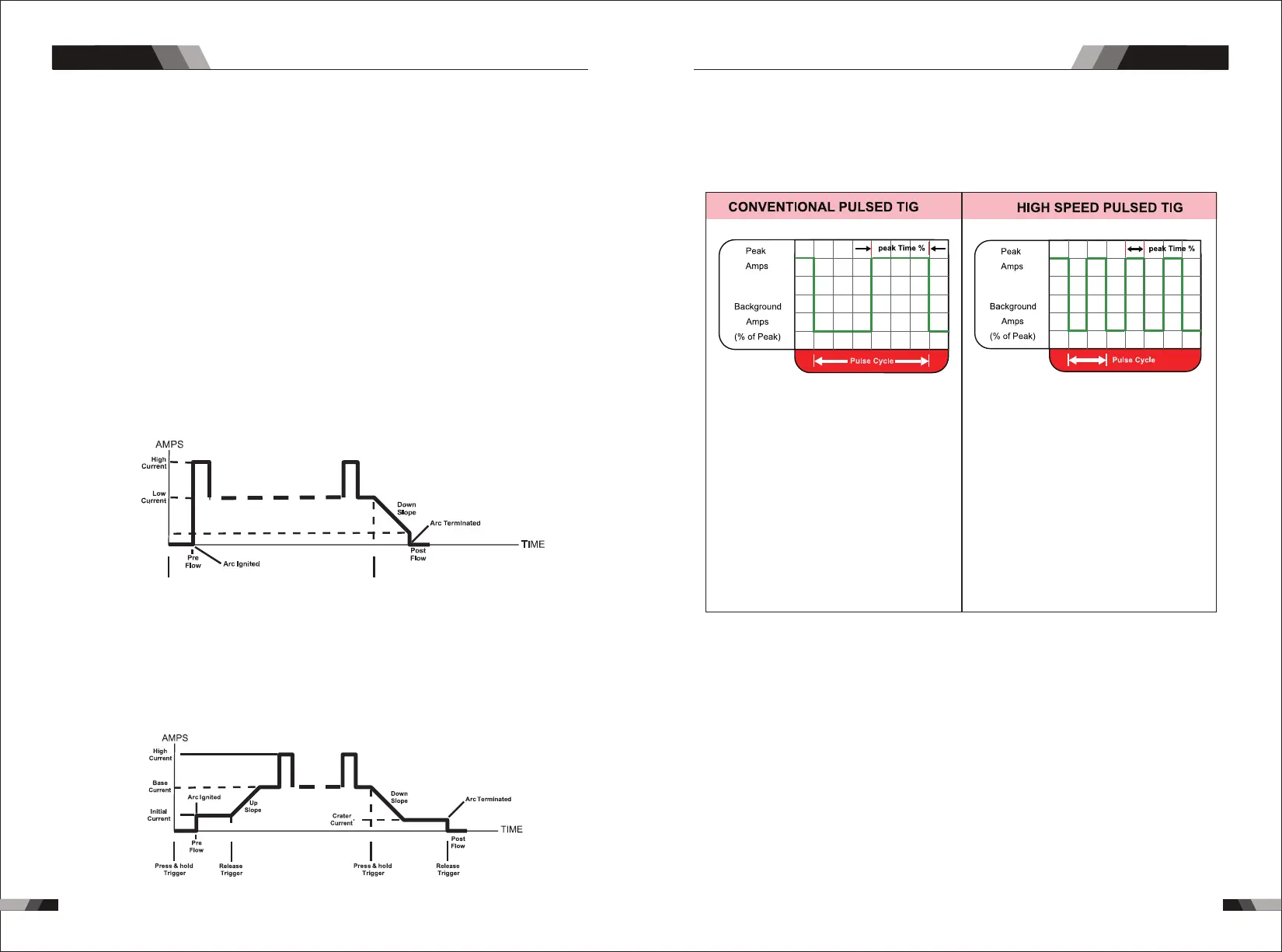

Operation

Operation

Minimum

Current

Press & hold

Trigger

Release

Trigger

Note: that when operating in GTAW (HF and LIFT TIG modes), the power source will

remain activated until the selected down slope time has elapsed

4T Latch mode this mode of welding is mainly used for long welding runs to reduce

operator fatigue. In this mode the operator can press and release the torch trigger and

the output will remain active. To deactivate the power source, the trigger switch must

again be pressed and released, thus eliminating the need for the operator to hold the

torch trigger.

12. Trigger Mode Control Button (HF TIG and LIFT TIG Mode only)

The trigger mode control is used to switch the functionality of the torch trigger between

2T and 4T.

output to be active.

Press and hold the torch trigger to activate the power source (weld). Release the torch

trigger switch to cease welding.

2T Normal Mode In this mode, the torch trigger must remain pressed for thewelding

9. Frequency Indicator (Hz)

Frequency indicator, when the setting programm in pulse frequency ,this indicator will

be on.

11. Thermal Overload Indicator Light

This welding power source is protected by a self resetting thermostat. The indicator will

illuminate if the duty cycle of the power source has been exceeded. Should the thermal

overload indicator illuminate the output of the power source will be disabled. Once the

power source cools down this light will go OFF and the over temperature condition will

automatically reset. Note that the mains power switch should remain in the on position

such that the fan continues to operate thus allowing the unit to cool sufficiently. Do not

switch the unit off should a thermal overload condition be present.

10. Power ON Indicator

The POWER ON indicator illuminates when the ON/OFF switch is in the ON position and

the correct mains voltage is present.

13. Process Selection Button

The process selection control is used to select the desired welding mode. Three

modes are available, MMA (Stick),GTAW (TIG) and CUT modes.

14. Pulse Button

Press the PULSE button to toggle Pulse On and OFF.

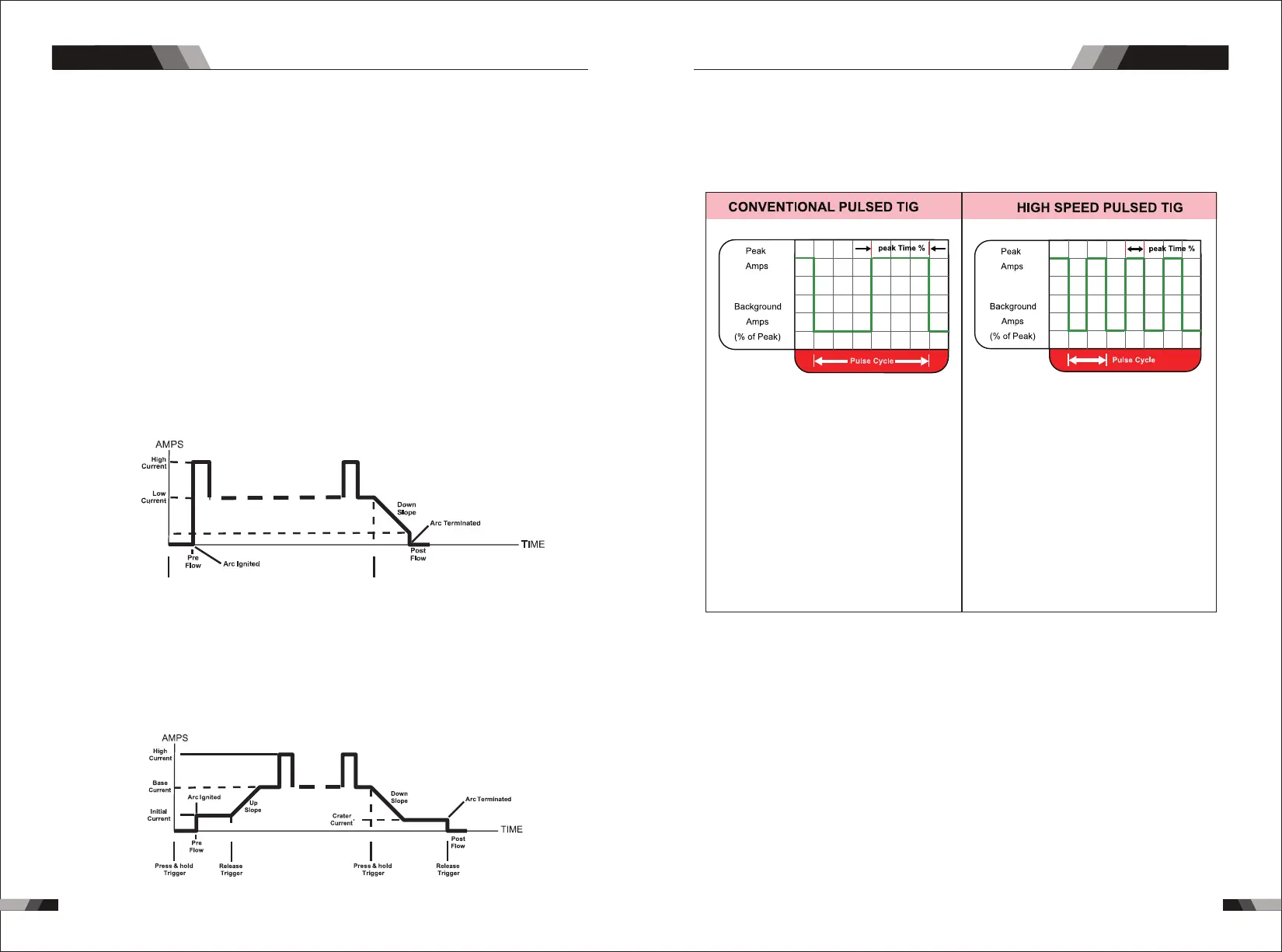

Typically from 1 to 10 PPS. Provides a heating

and cooling effect on the weld puddle and can

reduce distortion by lowering the average

amperage. This heating and cooling effect also

produces a distinct ripple pattern in the weld

bead. The relationship between pulse frequency

and travel speed determines the distance

between the ripples. Slow pulsing can also be

coordinated with filler metal addition and

increase overall control of the weld puddle

In excess of 40 PPS, Pulsed TIG becomes more

audible than visible-causing increased puddle

agitation for a better as-welded microstructure.

Pulsing the weld current at high speeds-between

a high Peak and a low Background amperage-

can also constrict and focus the arc.This results

in maximum arc stability, increased penetration

and increased travel speeds(Common Range:

100-500 PPS).

The Arc-Sharpening effects of high speed

pulsing are expanded to new dimensions. The

ability to pulse at 5,000PPS further enhances

arc stability and concentration potential-which

is extre mely beneficial to automation where

maximum travel tspeeds are required.

15. Programming Parameter Indicators

These indicator lights will illuminate when programming.

16. Positive Welding Terminal

Positive Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

and turned securely to achieve a sound electrical connection.

17. Negative Welding Terminal

Negative Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

18. Shielding Gas Outlet

The Shielding Gas Outlet located on the front panel is a fast connection of a suitable

TIG Torch.

AC/DC PLASMA SERIES EQUIPMENTAC/DC PLASMA SERIES EQUIPMENT

Loading...

Loading...