44

The infusion group is part of the NEO (New

Engine Optimization), that guarantees high

performance while reducing the energy

consumption of the machine. Hence this

group is different from common systems

with thermosiphon circulation. In fact, the

temperature of the group is ensured by the

presence of a heating element cartridge.

In addition, the thermal insulation prevents

heat dispersion.

The group is equipped with:

A heating element cartridge of 300 W;

A temperature probe that communi-

cates with the control unit;

Two 135°C high-limit thermostats con-

nected in series with the heating ele-

ment;

A three-way solenoid valve called coffee

valve.

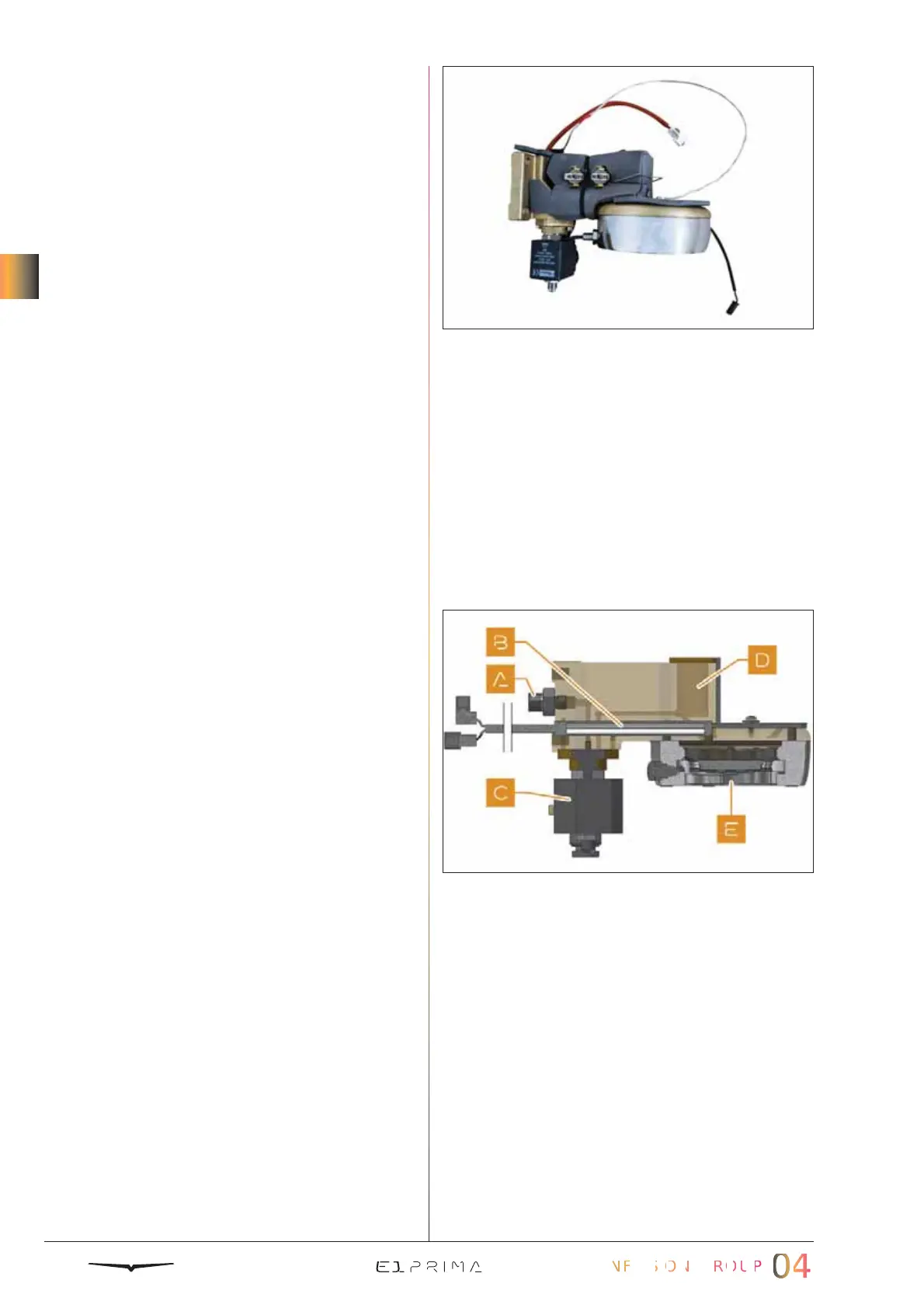

The group section shows:

Water supply into the group.

Heating element.

Coffee valve.

Pre-infusion chamber.

Water outlet.

The machine is provided by the SIS (Soft

Infusion System). It optimizes the extraction

and compensates any tamping errors so

that it reduces waste and makes regularly

perfect coffees. It is based on the pre-in-

fusion chamber, that increases the time

in which water without pressure wets the

coffee cake to provide a uniform extraction.

A cylinder in the chamber limits the space

and the dripping of water after the end of

extraction.

How does the water flow work? The water

enters the group (A) and the coffee valve

lets it pass through (C). Then the water fills

the pre-infusion chamber in about 3 sec-

onds (D) and, in the meantime, the coffee

cake is reached by the water (E) and is

naturally wet. Once the chamber is filled,

the pressure of 9 bar reaches the coffee,

initiating the extraction into the cup.

02

01

Loading...

Loading...