11

!

Please note

The ingress of oxygen can result in system dam-

age as a consequence of oxygen corrosion.

Only use pump controlled pressure maintaining

systems that are sealed against corrosion. The

pressure maintaining systems must be protected

against oxygen ingress into the heating water.

Pump controlled pressure maintaining systems

with atmospheric deaeration through cyclical

pressure release bring about central post-venti-

lation of the heating system. They do not pro-

vide oxygen removal in the sense of corrosion

protection as described in Directive VDI 2035

Part 2.

Carry out all checks in accordance with the manufac-

turer's instructions. Limit pressure fluctuations to the

lowest possible differential. Cyclical pressure fluctua-

tions and more significant pressure differentials point

towards a system fault. Immediately remedy such

faults or other heating system components may be

damaged.

Checking the firm seating of electrical plug connections and cable grom-

mets

Checking the thermal insulation

Checking the water quality

Observe the instructions in chapter "Water quality

requirements".

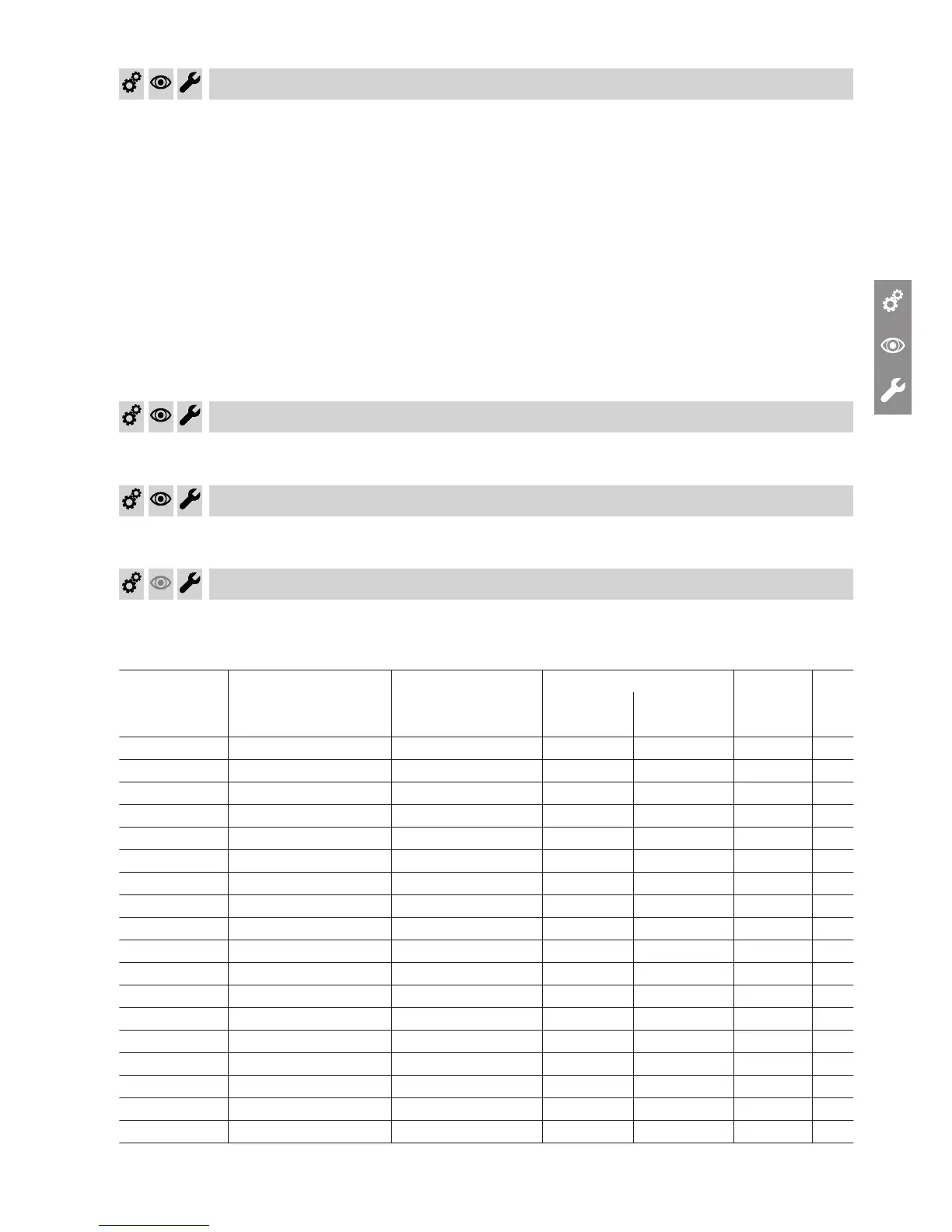

Enter the amount of top-up water and the total hard-

ness of the feed and boiler water into the table.

Meter reading Fill and top-up water Total water volume Total hardness pH value Date

Feedwater Boiler water

m

3

m

3

m

3

°dH °dH

Commissioning, inspection, maintenance

Checking the expansion vessel and system… (cont.)

5692 701 GB

Loading...

Loading...