18

5601 189 v1.1

Vitodens 100-W, WB1B Technical Data

IMPORTANT

Accessories for the Vitodens 100-W

Neutralization Unit for Single-Boiler Applications

with neutralizing granulate for Vitodens 100-W, WB1B 26, 35

Part No. 7134 231

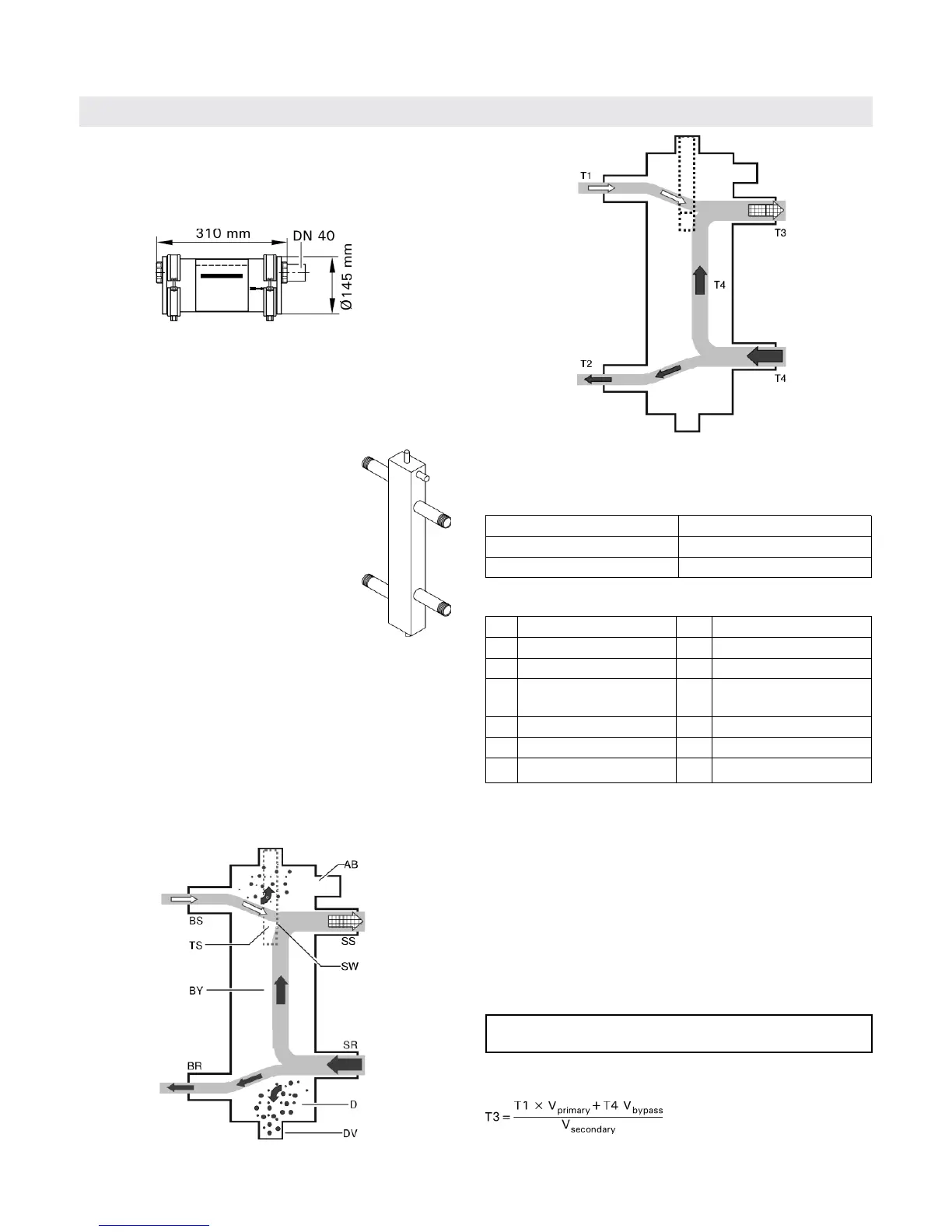

Low-Loss Header

- Type 80/50, Part No. 7134 791

[max. flow rate 17.6 GPM (4 m3/h)]

- Type 120/80, Part No. 7134 792

[max. flow rate 35.2 GPM (8 m3/h)]

A low-loss header offers additional benefits

not provided by a pair of closely spaced

tees. Viessmann strongly recommends

and prefers the use of a low-loss header

over closely spaced tees. When used in

conjunction with the Vitodens 100-W

boiler, the low-loss header acts as

hydraulic break, decoupling boiler and

system circuits from each other (no

sensor required). It is recommended to

use the low-loss header in applications in

which the total system flow rate exceeds

the maximum or falls below the minimum

flow rate of the Vitodens 100-W boiler.

Product may not look exactly as illustrated.

The low-loss header is available in the following sizes.

Select the size based on the maximum system flow rate

of your application.

Legend

V

primary

Boiler circuit flow rate

V

secondary

Heating circuit flow rate

V

bypass Bypass flow rate

Q

primary Heat supplied by boiler

Q

secondary Heat consumed by system

V

primary <

V

secondary

T1 > T3

T2 = T4

Q

primary =

Q

secondary

T1 176° F (80° C)

V

secondary=

V

primary+

V

bypass

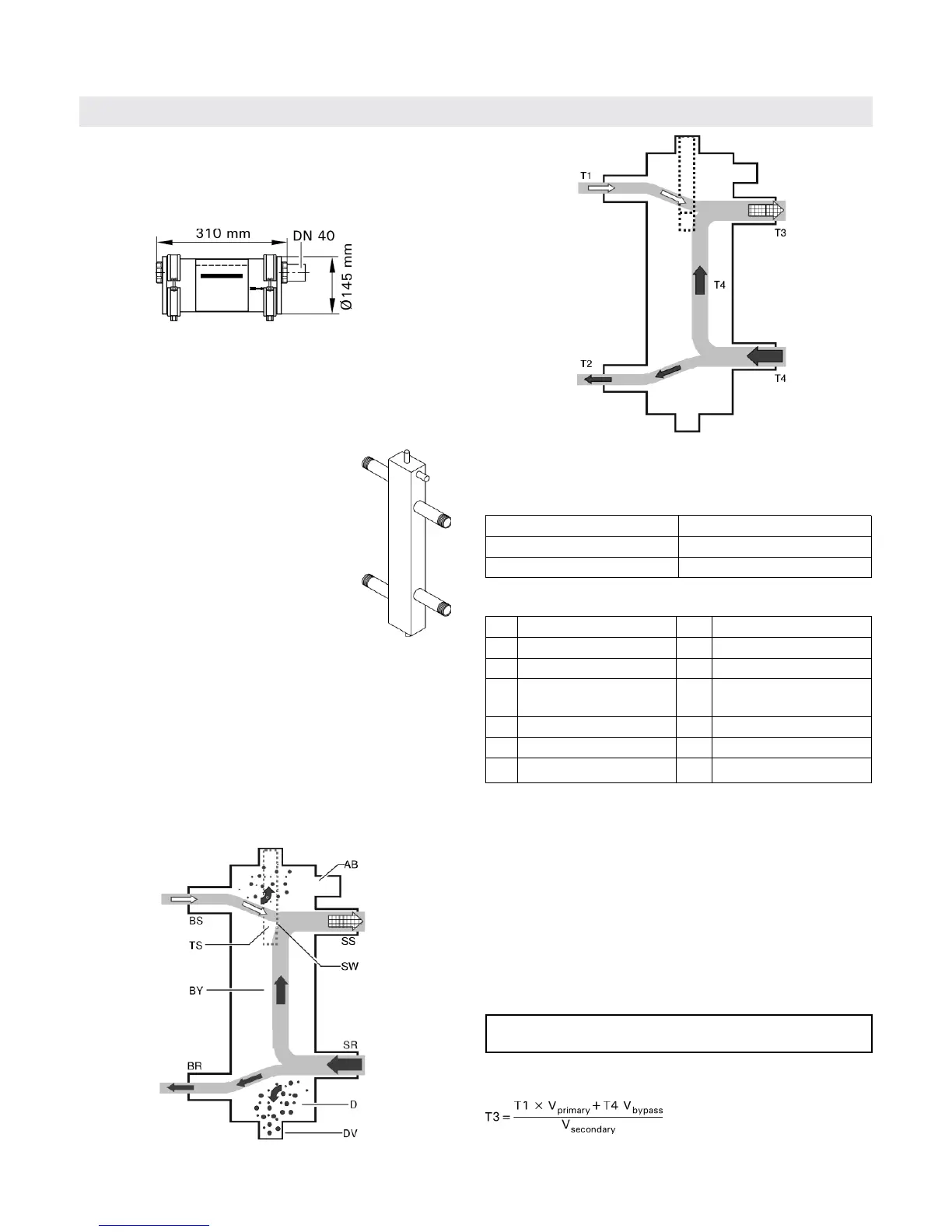

When installing a low-loss header, system mixed supply

temperature (T3) must be calculated as follows

For maximum boiler flow rates, see the table on page 11

in this manual.

Viessmann strongly recommends the use of a low-loss

header in cases where the system head and flow rates

are unknown.

In addition, the low-loss header helps eliminate air and

debris [D] from the heating system. See illustrations for

Low-loss header design and the principle of operation.

Product may not look exactly as illustrated.

Low-loss header design

Prinicpal of operation

V

prim

ary

V

bypass

V

secondary

AB Air Bleed DV Drain Valve

BR Boiler Return SR System Return

BS

Boiler Supply SS System Supply

BY Bypass

(with laminar flow)

TS Viessmann Temp.

Sensor (not used)

D Debris and/or air SW Sensor Well

T1 Boiler supply temp. T3 System supply temp.

T2 Boiler return temp. T4 System return temp.

Model No. Max. system flow rate

Type 80/50 17.6 GPM (4 m3/h)

Type 120/80 35.2 GPM (8 m3/h)

Installation

Accessories

Loading...

Loading...