13

x

x

x

x

x

x

x

x

x

x

x

x

x

a

7511001

9.2) Check and replacement of nuts

The two upper and lower nuts coupled to the lead screw

and placed in the column, during the machine operation

the wear is proportionally to the number of cycles and

to the load applied to the platform (people weight).

Therefore, it is necessary to replace the nuts after a

certain number of cycles.

The thread wear of the nuts brings them gradually

closer.

The distance between the two nuts must not be lower

than a certain limit value marked next to the slot (Fig.

11/a).

The initial value – measured during the machine as-

sembly – is also marked next to the slot (Fig. 11/a).

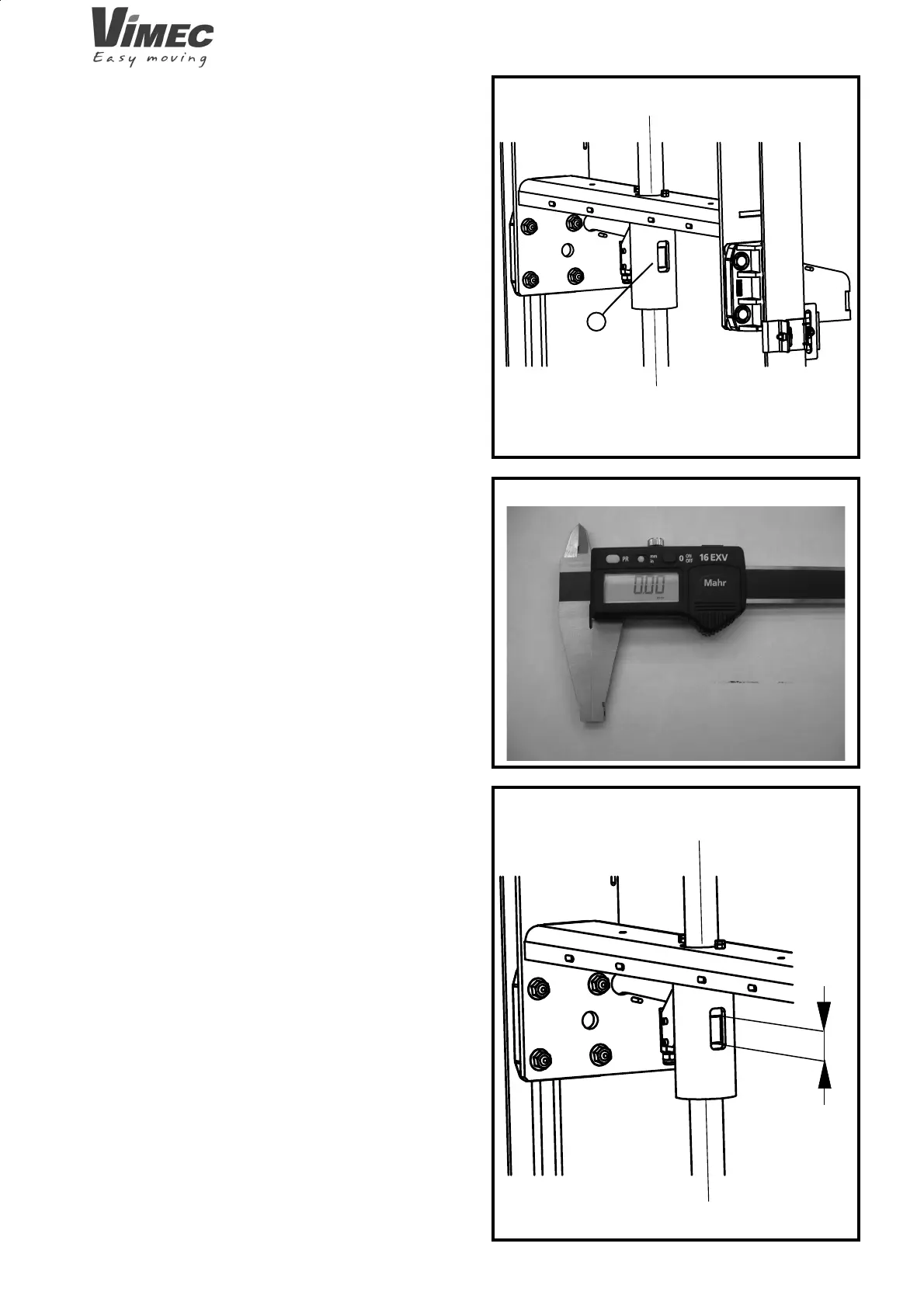

Then it is necessary to measure the distance between

the two nuts with a gauge, and such value must range

between the initial value (higher fi gure) and the limit

value (lower fi gure).

If the distance measured with the gauge is lower than

the limit value, the nuts must be replaced.

The following operations must be carried out to measure

the distance between the bushes:

- Remove the column guard.

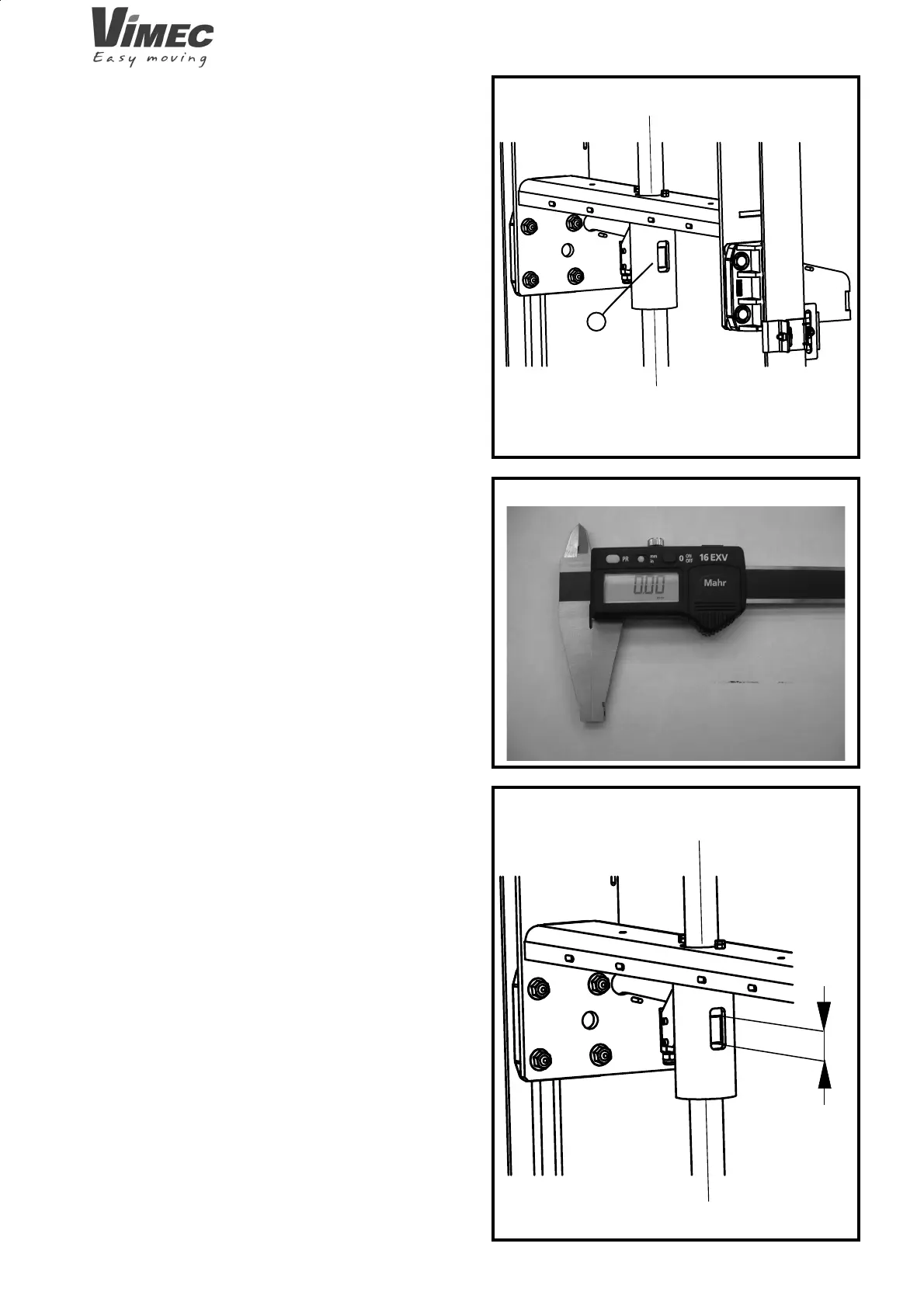

- Measure the “X” distance between the two nuts (Fig.

13) with a long-clip gauge (see Fig. 12).

- Reassemble the casings and tighten all screws!

Restore the same conditions as before checking.

This check shall be carried out every 6 months

together with all the other periodical maintenance

checks.

FIG.11

FIG.13

FIG.12

7512001

Loading...

Loading...