16

a

a

a

b

c

7511001

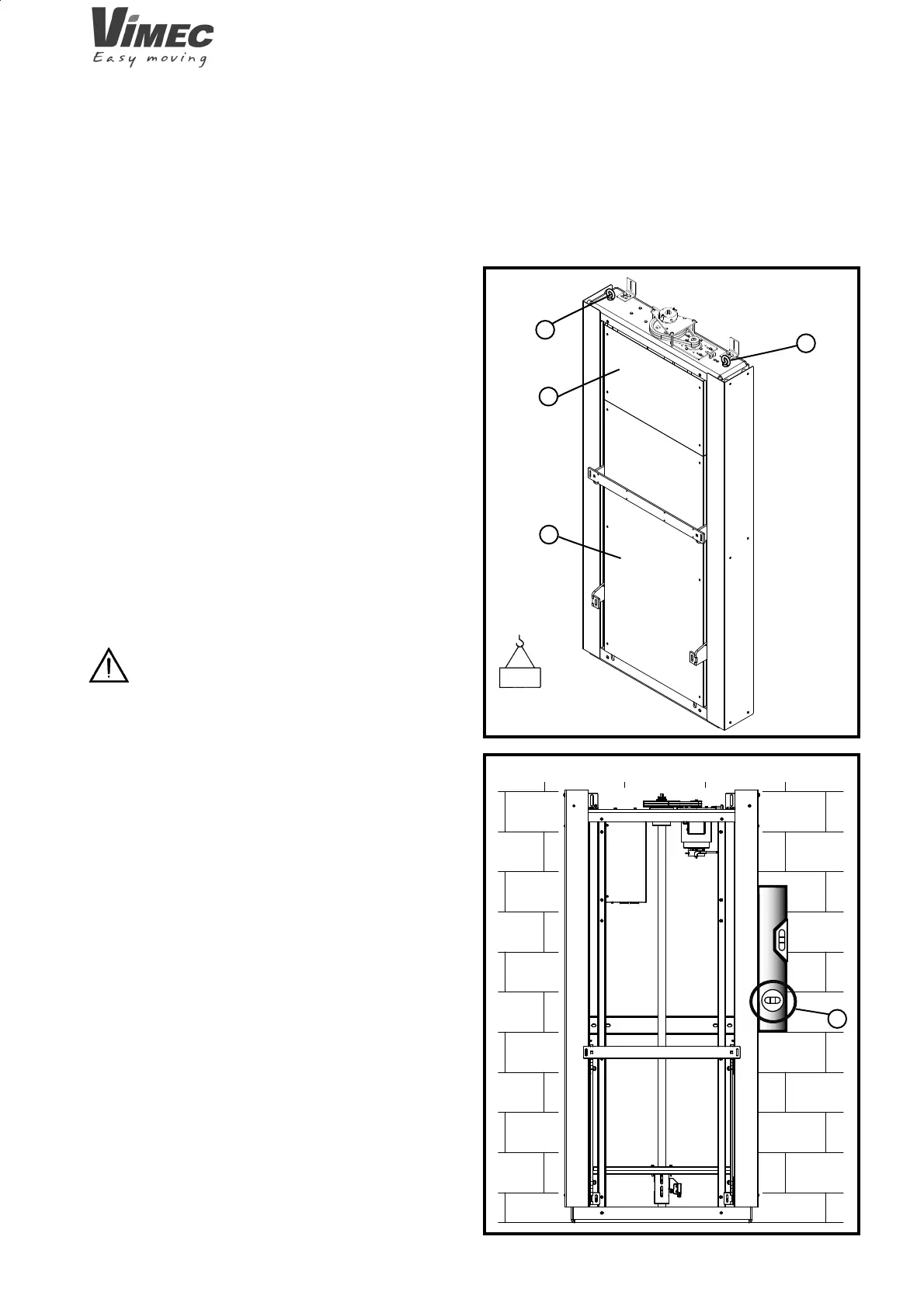

1. LIFT SUPPLY PACKAGE

Machine with 1100/1600 mm stroke

- Complete platform

- Preassembled column

- Upper fl oor gate complete with controls

- Panelling

- Remote call column (OPT)

Machine with stroke greater than 1600 mm

- Complete platform

- Decomposed column

- Upper fl oor gate complete with controls

- Panelling

- Remote call column (OPT)

2. PLACE OF INSTALLATION

The lift may be installed INDOORS or OUTDOORS.

3. TRANSPORT

3.1) Handling

The lift, disassembled and on a pallet, must be handled

with the aid of suitable lifting equipment with rated load

at least 250 kg (Fig. 1).

Follow the instructions provided in chap. 4

of the assembly manual with regard to the correct

procedures for lifting and positioning the unit.

3.2) Storage

- Store the unit in a dry place

- Protect from dust with PVC sheeting.

FIG.1

FIG.2

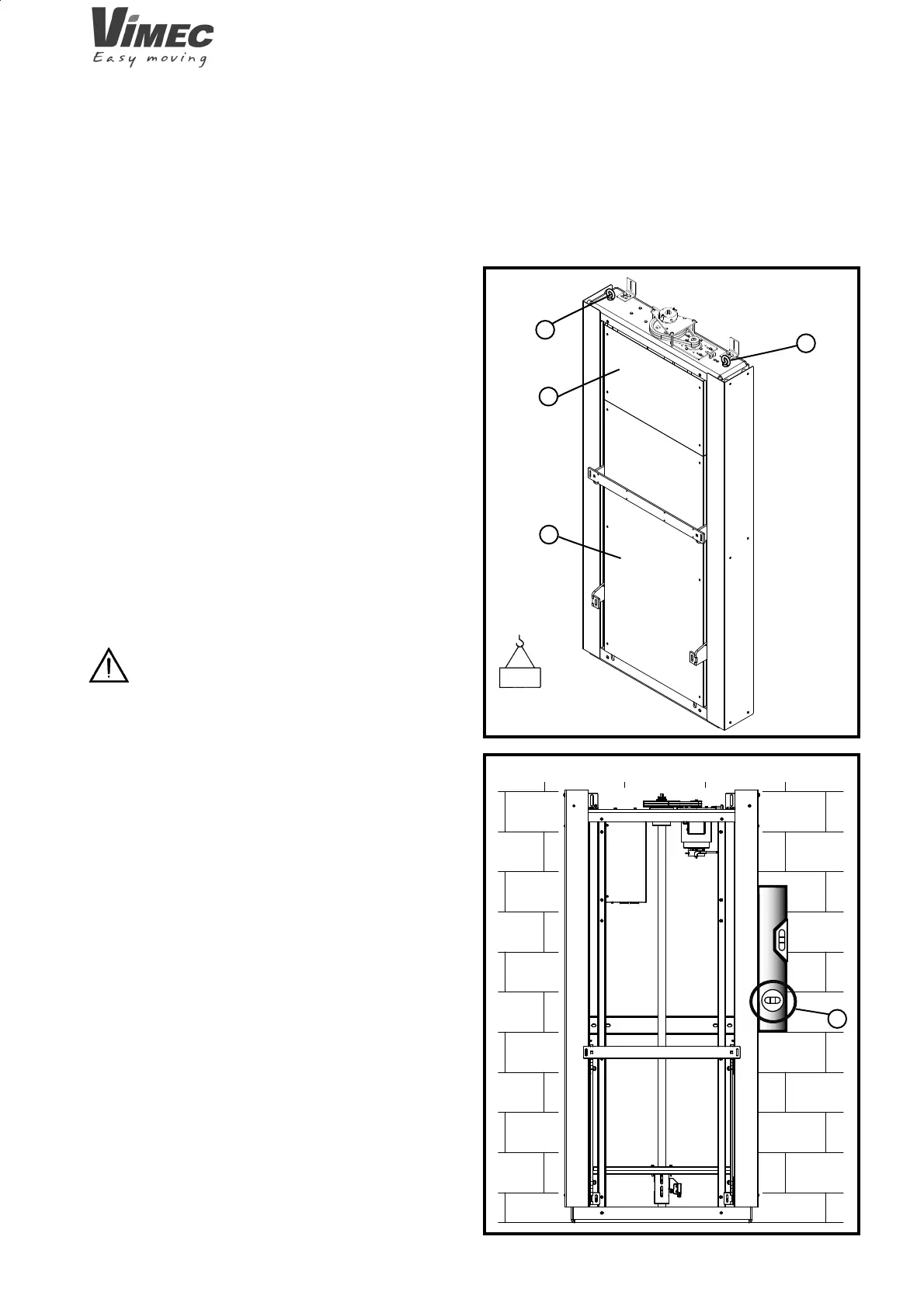

4. INSTALLATION INSTRUCTIONS

- Check that the lift and shaft dimensions are as stated

on the installation drawings.

- Check that the mains voltage specifi cations correspond

to those stated on the lift’s nameplate.

- Check that raceways have been provided for the power

supply cables and that a water drainage pit has been

constructed if necessary.

- Check that the base plinth on which the lift is to rest

is level.

- Place the lift in the intended position, with the distances

from the wall shown in the installation diagrams.

4.1 Wall column assembly for a machine with a

stroke under 1600 mm

- Use the eyebolts to remove the column from the

packaging and from the crate (Fig.1/a) and remove

any front casings (Fig. 1/b-1/c).

250 kg

7512001

Loading...

Loading...