27

Maintenance

Maintenance

7.6 Mechanical Seal

The mechanical seals used as standard in the MD series pumps are of the unbalanced internal single spring type. This spring

produces the minimum contact force between the sealing surfaces of the rotating and stationary units. The stationary unit is

mounted on the union body in an elastomer cup. Its design allows the sealing surfaces to remain in contact, even if natural

wear or axial and radial oscillations occur in the rotation of the unit. These seals consist of the following elements:

Table Nº 6

NI-Resist

Coal

Vitón

Vitón

AISI 302

AISI 302

Mechanical Seal

PAC-SEAL Type 21 Seal

Mono-Spring, Unbalanced

Ceramics

Coal

Buna

Buna

AISI 302

AISI 302

Stationary Ring

Contact Face

Elastomeric Semi Bellows

Cup Type Seat

Spring

Chassis

A

B

C

D

E

F

Basic Alternative

Tungsten

Tungsten

Vitón

Vitón

AISI 304

AISI 316

AISI 316

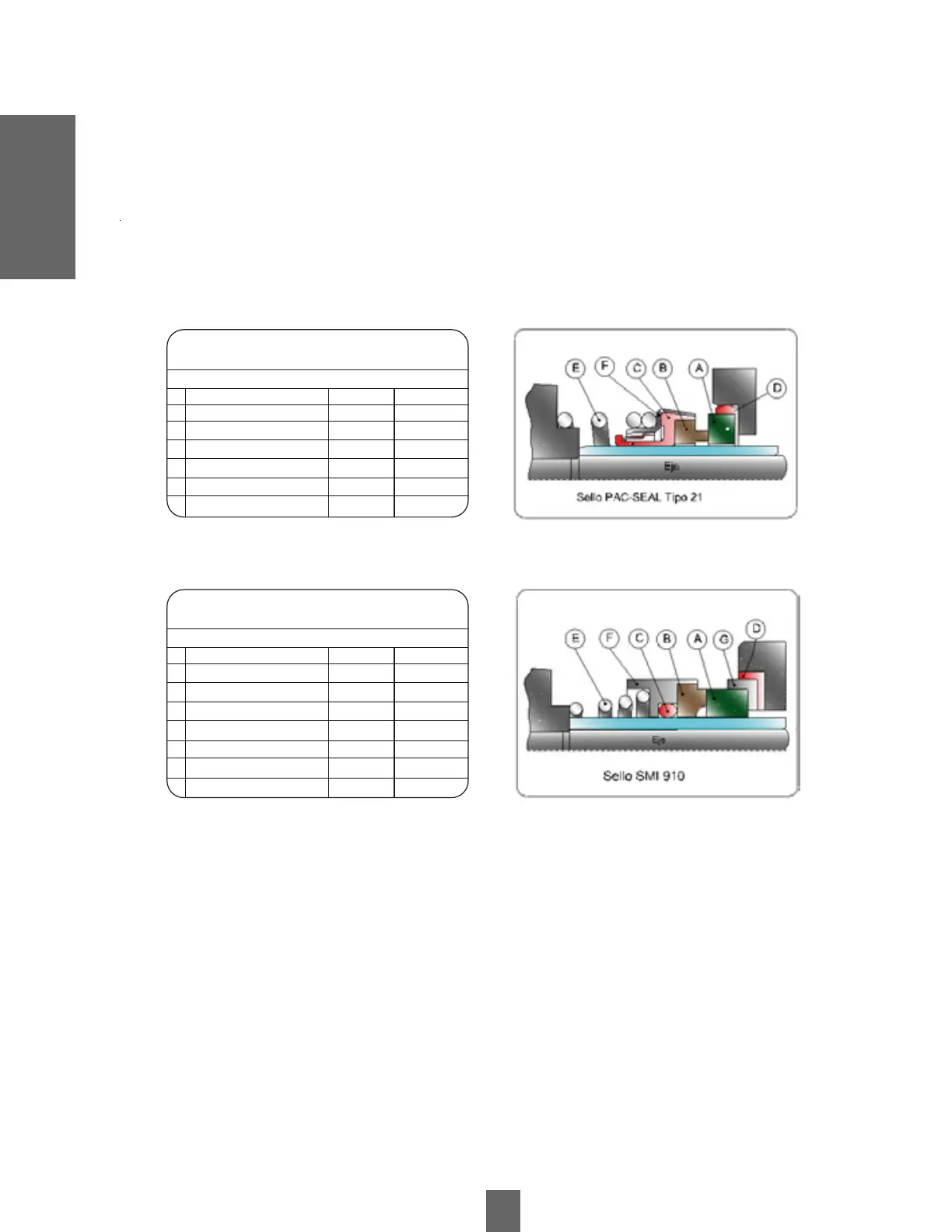

Mechanical Seal

Seal SMI 910

Mono-Spring, No, Balanced

Tungsten

Coal

EPR

EPR

AISI 304

AISI 316

AISI 316

Stationary Ring

Contact Face

Secondary Seal

Cup Type Seat

Spring

Chassis

Stationary Ring Holder

A

B

C

D

E

F

G

Basic Alternative

Table Nº 5

Figure 20

Figure 21

Newly installed mechanical seals may leak liquid between their sealing faces, this is small and should diminish with some

time of operation. Mechanical seals do not require maintenance, but when they have completed their service life, they

should be replaced completely with new seals.

When a seal is to be installed, always remember that it should be done with the utmost care and cleanliness, so the contact

protection between the two sliding surfaces should be removed only at the time of assembly.

There are several other sealing systems for pumps of the MD, MDE, HDE series, for example:

• Balanced Inner Multi-Spring Balanced Inner Seal

• Balanced outer multi-spring seal

• Double seal

• Bellows type seal

• Cartridge type seal

Loading...

Loading...