24

g. 37

7.3.2 GAS VALVE MAXIMUM SETTING

Set the CO

2

button at maximum (see 7.3.1), once the maximum

is obtained check that it corresponds with the appropriate CO

2

value (Maximum) for the respective appliance (see 2.11). If

the CO

2

reading is correct, proceed to gas valve minimum

setting (7.3.3).

However, if the CO

2

reading is incorrect, the maximum gas

pressure must be adjusted as follows:

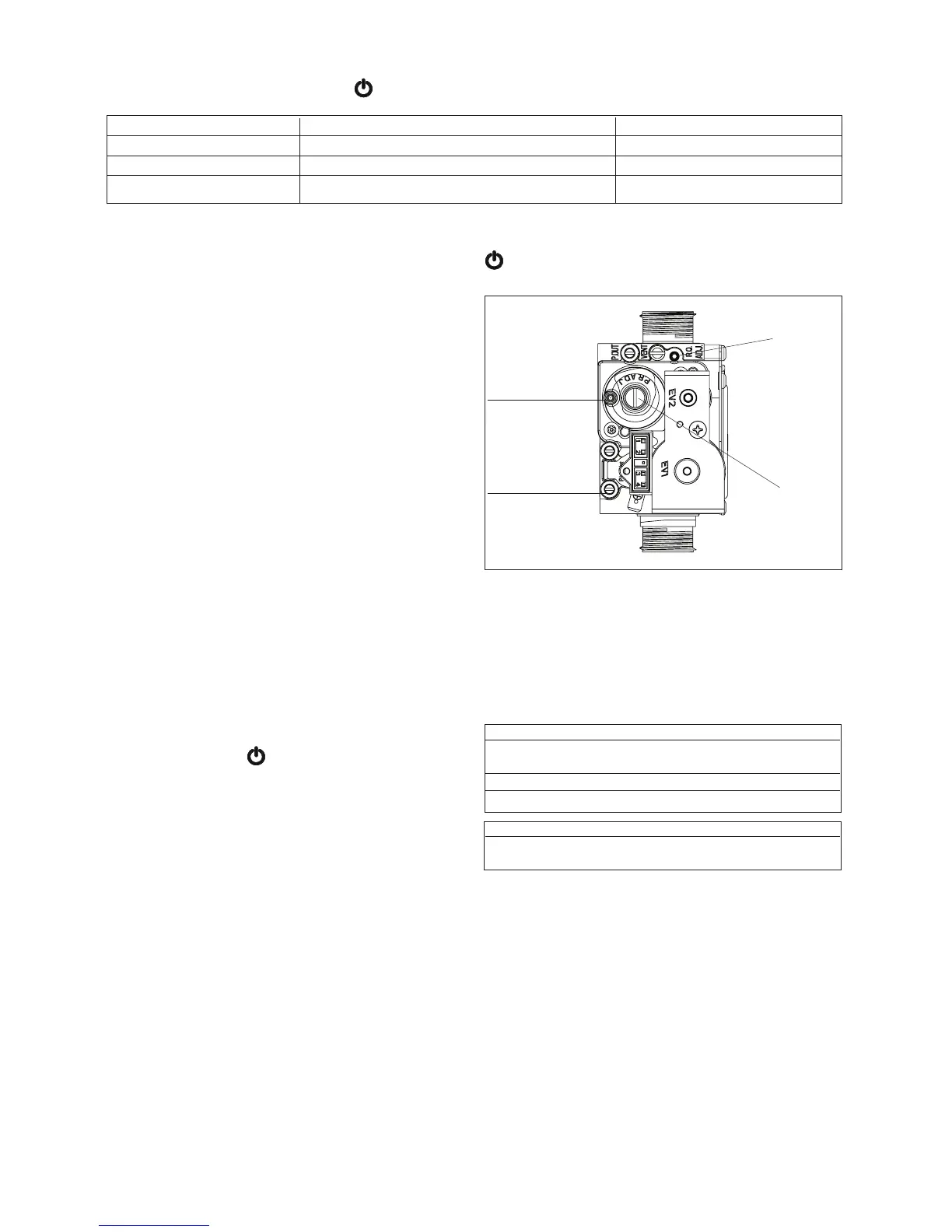

• using a 2.5mm Allen key, very slowly turn the maximum ad-

justment screw (see g. 37) – clockwise to decrease, counter

clockwise to increase – until the correct value is displayed on

the CO

2

analyser (allow time for the analyser to stabilise).

7.3.3 GAS VALVE MINIMUM SETTING

Set the CO

2

button at minimum (see 7.3.1), once the minimum

is obtained check that it corresponds with the appropriate CO

2

value (Minimum) for the respective appliance (see 2.11). If the

CO

2

reading is correct, proceed to completion (7.3.4).

However, if the CO

2

reading is incorrect, the minimum gas

pressure must be adjusted as follows:

• locate the minimum adjustment screw (g. 37), using a suit-

able screwdriver remove the protection plug

• using a 4mm Allen key, very slowly turn the minimum adjust-

ment screw (see g. 37) - clockwise to increase, counter

clockwise to decrease - until the correct value is displayed

on the CO

2

analyser (allow time for the analyser to stabilise).

7.3.4 COMPLETION

On completion of the combustion analysis check and/or any

gas valve adjustment, ret the plug (g. 36 L2) and move the

mode selector throught

position. Remove the test probe

from the test point and ret the sealing screw/s and/or cap.

IMPORTANT

A GAS TIGHTNESS CHECK MUST BE CARRIED OUT IF ANY

GAS CARRYING COMPONENTS HAVE BEEN REMOVED,

REPLACED OR DISTURBED.

7.4 COMBUSTION ANALYSIS TEST

A combustion analysis check can easily be carried out on the

appliance via the test points located on the top of the applian-

ce (see 7.3).

• Operate the boiler in combustion analysis mode (see 7.3.1)

• Insert the ue gas analyser probe into the ue gas test point

(see g. 33) and compare the values with those shown in

section 2 (Nat. Gas) or section 10 (LPG). If different adjust

the gas valve according to 7.3.1, 7.3.2, & 7.3.3.

The appliance will operate in CO2 mode for approximately

15minutes.

Note: If a measured CO/CO2 ratio of 0.004/1 or less AND a

CO reading of less than 350ppm cannot be achieved, please

contact Vokera technical for advice.

7.5 CHECKING THE EXPANSION VESSEL

Carry out the component removal procedure as described in

6.4. You must ensure that the boiler is completely drained of

water. Using a suitable pressure gauge, remove dust cap on

expansion vessel and check the charge pressure. The cor-

rect charge pressure should be 1.0 bar ± 0.1 bar. If the charge

pressure is less, use a suitable pump to increase the charge.

7.3.1 CO

2

FUNCTION SETTINGS

Locate the CO

button (see 7.3)

Select the main selector switch in position

CO

2

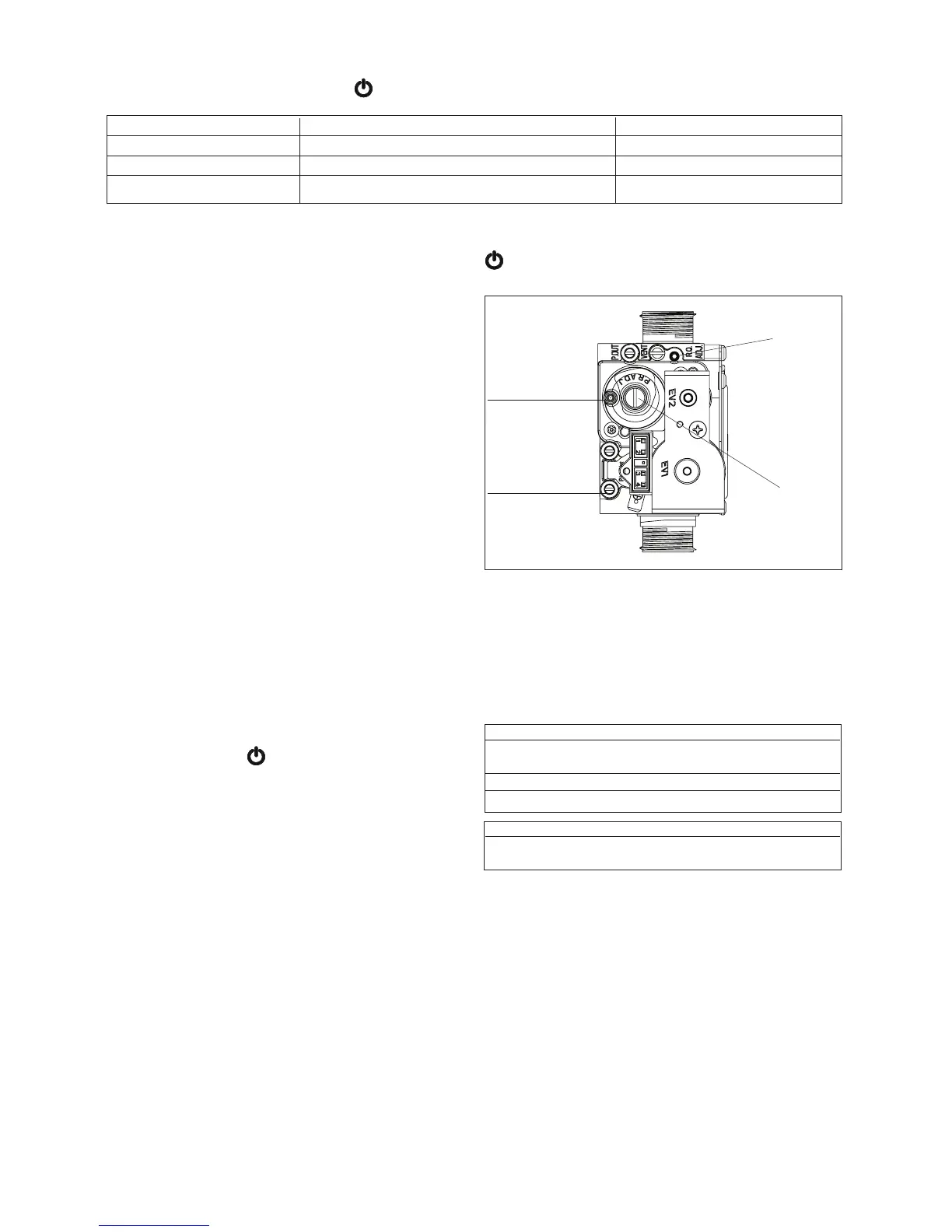

FUNCTIONS ACTION ON THE BUTTON LED STATUS

combustion analysis mode press once = burner running at maximum heating yellow led blinking

gas valve maximun setting press twice = burner running at maximum DHW yellow led blinking + red led xed

gas valve minimum setting press three time = burner running at minimum yellow led blinking + green led xed

NOTE

1 - Any additional pressing of CO

button after the third time the burner switched between maximum DHW and minimum.

2 - To restart the CO

function it is necessary to pass throught the position with the main selector switch

NOTE

You must ensure the drain valve is in the open position whilst

re-charging takes place. Replace the dust cap and carry out

the relevant commissioning procedure (section 5).

7.6 EXTERNAL FAULTS

Before carrying out any faultnding or component replacement,

ensure the fault is not attributable to any aspect of the installation.

7.6.1 INSTALLATION FAULTS

Symptom Possible cause

No led/ignition Check wiring/check electrical

supply

No hot water Check pipe-work

No heating Check external controls

Fault Possible cause

Red led xed Check gas supply, check ue

system, check polarity

7.7 ELECTRICAL CHECKS

Any electrical checks must be carried out by a suitably quali-

ed person.

7.7.1 EARTH CONTINUITY TEST

Isolate the appliance from the electrical supply, and using a

suitable multi-meter carry out a resistance test. Connect test

leads between an appliance earth point and the earth wire of

the appliance supply cable. The resistance should be less than

1 OHM. If the resistance is greater than 1 OHM check all earth

wires and connectors for continuity and integrity.

7.7.2 SHORT CIRCUIT CHECK

Isolate the appliance from the electrical supply, and using a

suitable multi-meter, carry out a short circuit test between the

Live & Neutral connections at the appliance terminal strip.

Repeat above test on the Live & Earth connections at the ap-

pliance terminal strip.

NOTE

Should it be found that the fuse has failed but no fault is in-

dicated, a detailed continuity check will be required to trace

Minimum

screw

Inlet gas pressure

connection

Compensation pipe

connection

Maximum

screw

Loading...

Loading...