14

IMPORTANT

The vertical ue terminal is 1.0 metre in length and cannot be

cut; therefore it may be necessary to adjust the height of the

appliance to suit or use a suitable extension.

Connect the vertical ue assembly to the boiler ue spigot us-

ing the 100mm clip, gasket & screws (supplied), ensuring the

correct seal is made. The ue support bracket (supplied with

the vertical ue kit) can now be tted.

If the vertical ue requires extension/s or additional bend/s,

connect the required number of ue extensions or bends (up

to the maximum equivalent ue length) between the boiler and

vertical ue assembly (see g. 14).

Ensure that any horizontal sections of the ue system have a

minimum 1º; maximum 3º fall back to the boiler (1º = 17mm

per 1000mm).

NOTE

When cutting an extension to the required length, you must

ensure that the excess is cut from the plain end of the exten-

sion. Remove any burrs, and check that any seals are located

properly.

You must ensure that the entire ue system is properly sup-

ported and connected.

4.5.3 TWIN FLUE SYSTEM

The Vokèra twin ue system enables greater ue distances

to be achieved than that of a concentric ue system. It can be

used for horizontal or vertical applications, however the twin

ue system must be converted to the dedicated concentric

ue kit for termination. It is essential that the installation of the

twin ue system be carried out in strict accordance with these

instructions.

GUIDANCE NOTES ON TWIN FLUE INSTALLATION

• The ue must have a have a minimum 1º; maximum 3º (1º =

17mm per 1000mm) fall back to the appliance to allow any

condensate that may form in the ue system to drain via the

condensate drain. Consideration must also be given to the fact

that there is the possibility of a small amount of condensate

dripping from the terminal.

• Ensure that the entire ue system is adequately supported,

use at least one bracket for each extension.

• The entire ue system must be adequately insulated to

maintain heat within the ue system thereby reducing the

possibility of condensate production.

• As the exhaust outlet pipe can reach very high temperatures

it must be protected to prevent persons touching the hot

surface.

• The condensate drain pipe must be connected in accordance

with building regulations.

Reduction for bends

Twin ue accessories

Part No. Description Length

0225805 Horizontal ue terminal 1.0 metre

0225810 Vertical ue terminal 1.0 metre

359 Twin adapter kit N/A

531 Pitched roof ashing plate N/A

532 Flat roof ashing plate N/A

0225815 Condensate drain kit N/A

0225820 0.25m extension (pair) 250mm

0225825 0.5m extension (pair) 500mm

0225830 1.0m extension (pair) 1000mm

0225835 2.0m extension (pair) 2000mm

0225840 45º bend (pair) N/A

0225845 90º bend (pair) N/A

0225850 Twin bracket (5) N/A

0225855 Single bracket (5) N/A

MOUNTING THE BOILER

The xing holes for the wall-mounting bracket should now be

drilled and plugged, an appropriate type and quantity of xing

should be used to ensure that the bracket is mounted securely.

Fig. 13a

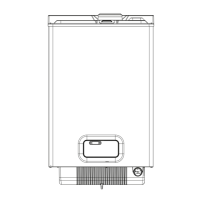

HORIZONTAL TERMINATION (g. 13c)

The twin ue system must be converted to the dedicated con-

centric ue kit for termination.

• The horizontal terminal is supplied with a built-in converter

box and cannot be shortened.

• A 130mm hole is required for the passage of the concentric

terminal through the wall.

• The air inlet pipe must always be level with or below, that of

the exhaust pipe.

Depending on site conditions it may be preferable to install the

terminal assembly prior to tting the twin ue pipes.

Mark and drill a level 130mm hole for the passage of the horizontal

ue terminal. Insert the terminal assembly into the ue hole.

Push-t the twin ue pipes onto the concentric to twin converter

box ensuring that the exhaust pipe connects to the exhaust

connection on the concentric to twin converter.

If necessary cut the plain ends (male) of the twin ue pipes to

allow connection to the concentric to twin converter.

NOTE

Before cutting twin ue pipes ensure allowances have been

made for connection onto the previous piece and onto the con-

centric to twin converter. The last twin ue pipes must be pushed

50mm onto the male spigots of the concentric to twin converter.

NOTE

Seal the ue terminal assembly to the wall using cement or a

suitable alternative that will provide satisfactory weatherproof-

ing. The interior and exterior trim can now be tted.

VERTICAL TERMINATION (g. 14)

The twin ue system must be converted to the dedicated con-

centric ue kit for termination.

• The vertical terminal is supplied with a built-in converter box

and cannot be shortened.

Once the bracket has been secured to the wall, mount the ap-

pliance onto the bracket.

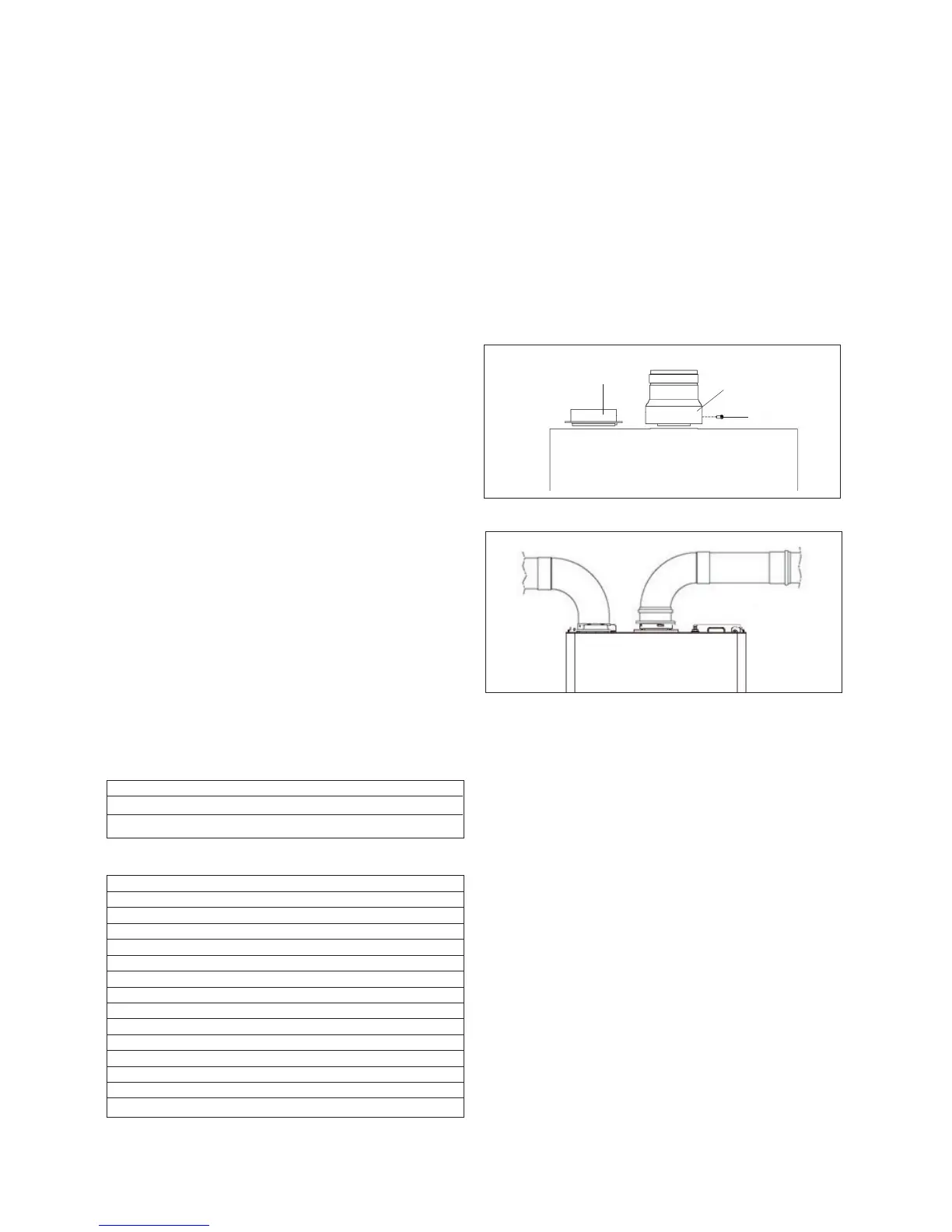

INSTALLATION OF TWIN ADAPTOR KIT (g. 13a-13b)

• Insert the exhaust connection manifold (A) onto the appliance

ue outlet.

• Remove the blanking plate (located to the left of the appliance

ue outlet) and – using the same screws – install the air inlet

plate (B).

• Using the hole in the exhaust connection manifold as a guide,

drill a 3mm hole in the appliance ue spigot and secure the

exhaust manifold connection to the ue spigot using the screw

provided (C).

• Using the two holes in the air inlet plate as a guide, drill a

3mm hole in each and secure the air inlet pipe/bend using

the screws provided.

The twin ue pipes extensions and accessories can now be

installed by pushing together (the plain end of each extension

or bend should be pushed approximately 50mm into the female

socket of the previous piece).

B

A

C

Bend Reduction in maximum ue length for each bend

45º bend 1.0 metre

90º bend 1.5 metre

Fig. 13b

Loading...

Loading...