WWW.VORONDESIGN.COM

CAD version: ERCF V2

143143

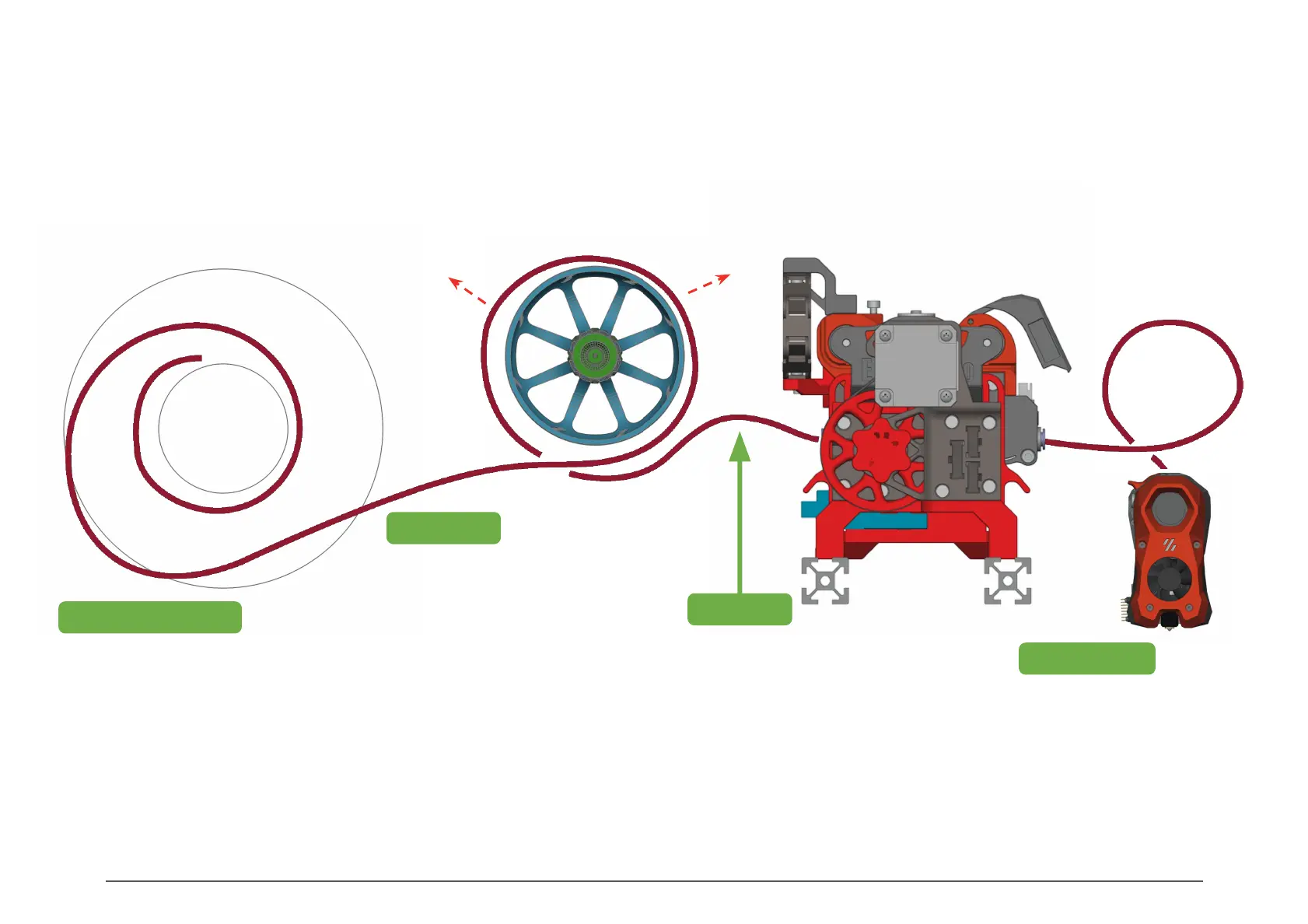

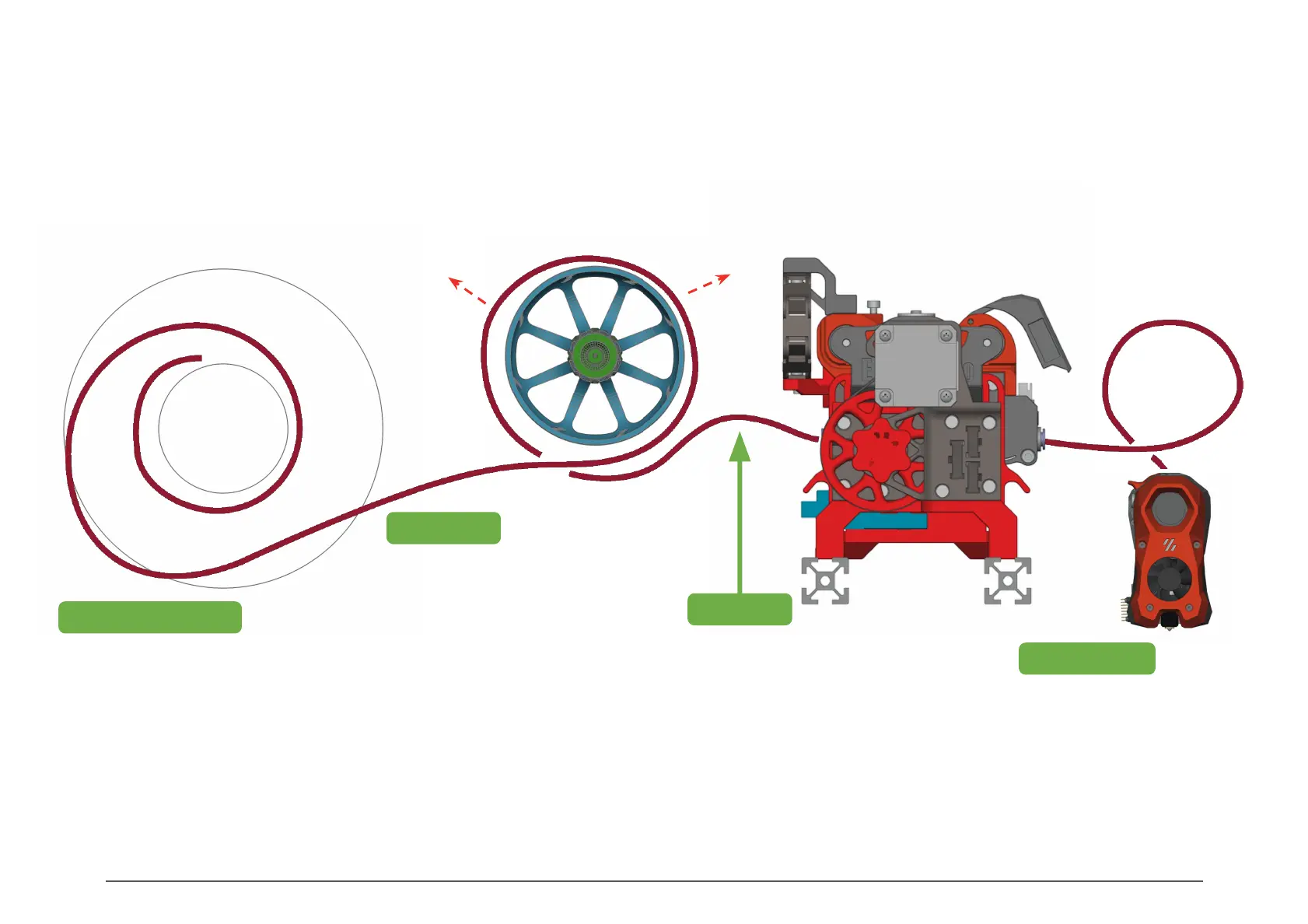

FILAMENT SPOOL

BEST PRACTICES FOR FILAMENT TUBE MANAGEMENT

It is important to optimize your tube path to reduce any resistance for your MMU setup.

This is to ensure that the path you choose does not go against the natural curl of your

filament. ERCT, as an example is designed to support many of these best practices.

ERCF

Many buffer designs require

optimal paths that come into

the ERCF to reduce pressure

on the filament blocks. It is

important in reducing that

pressure by not allowing

downward orientations. The

tube as well should not be

too long or it meets

additional resistance.

The ideal location for your filament

spool will depend on how it feeds

the buffer. The curl should

naturally work with the path

(filament and tube) that goes into

the buffer. In this example feeding

around to the back and below

allows for the natural curl to

remain in the tube to the buffer.

FILAMENT TUBE MANAGEMENT

BUFFER

When the buffer is fed by the

filament, the natural curl

should also follow the wheel of

the buffer. Depending on the

choice of buffer design, this

should be configured in such

way, to follow the buffering

expansion. It is essential that

the buffer does not pull back

filament on the encoder.

A final turn to the toolhead

can help maintain the natural

curl. This doesn’t have to be

small, and can be a large

radius but shouldn’t be too

long that will introduce

additional resistance.

TOOLHEAD

Loading...

Loading...