Page 35

Section 7

Sensor Adjustment & Component Testing

Sensor Installation Test (ECU Part

Numbers 472 500 012 and 472 500 013 0)

Purpose of Test: To verify proper sensor gap,

sensor hook-up to the ECU, ABS valve operation,

and pneumatic plumbing connections of the

WABCO Easy-Stop™ ABS on a new trailer.

1. Remove power from the ABS.

2. Raise sensed wheels so that they may

be rotated.

3. Go to the diagnostic tool. Reapply power to

the ABS.

앫 If there is no diagnostic tool on the trailer,

temporarily install one for this test. You

must use a diagnostic tool to complete the

Sensor Installation Test.

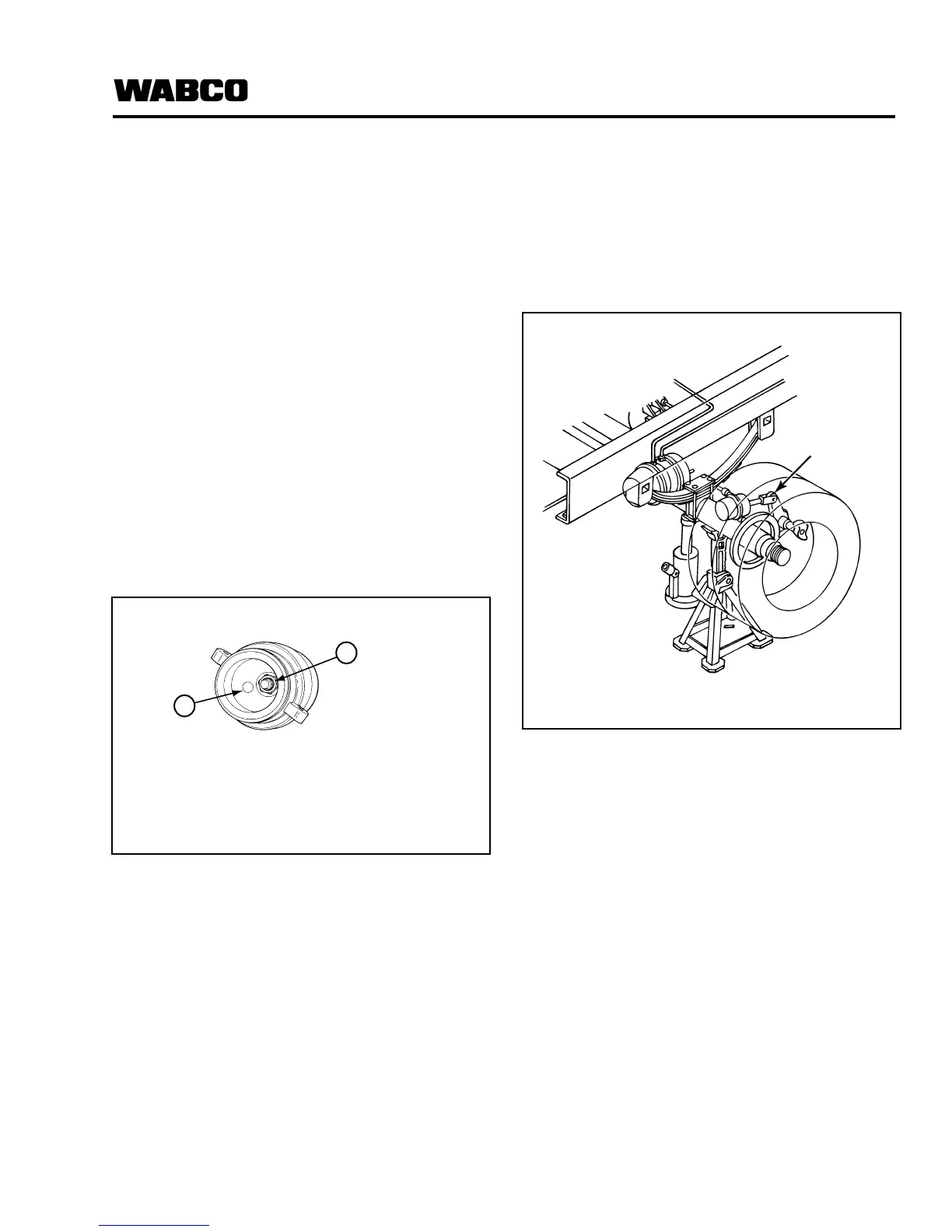

4. Check the diagnostic tool to verify the status of

the yellow LED. Figure 7.3 .

앫 If LED comes ON and stays ON, go to Step 5.

앫 If LED does not light, verify adequate power

is applied to the system. Make the

necessary repairs.

5. Press and release the blink code switch three

times for Sensor Installation Test Mode, one

second each time, separated by a release time

of one second.

앫 The LED should display eight rapid flashes.

This indicates the Sensor Installation Test

Mode. Then, the LED will continuously

display the system configuration code:

– 2 Flashes = 4S/3M

– 3 Flashes = 4S/2M

– 4 Flashes = 2S/2M

– 5 Flashes = 2S/1M

앫 If this does not occur, repeat Step 4.

앫 Attach the emergency and control air lines to

the trailer. Fill air tanks to release the spring

brakes.

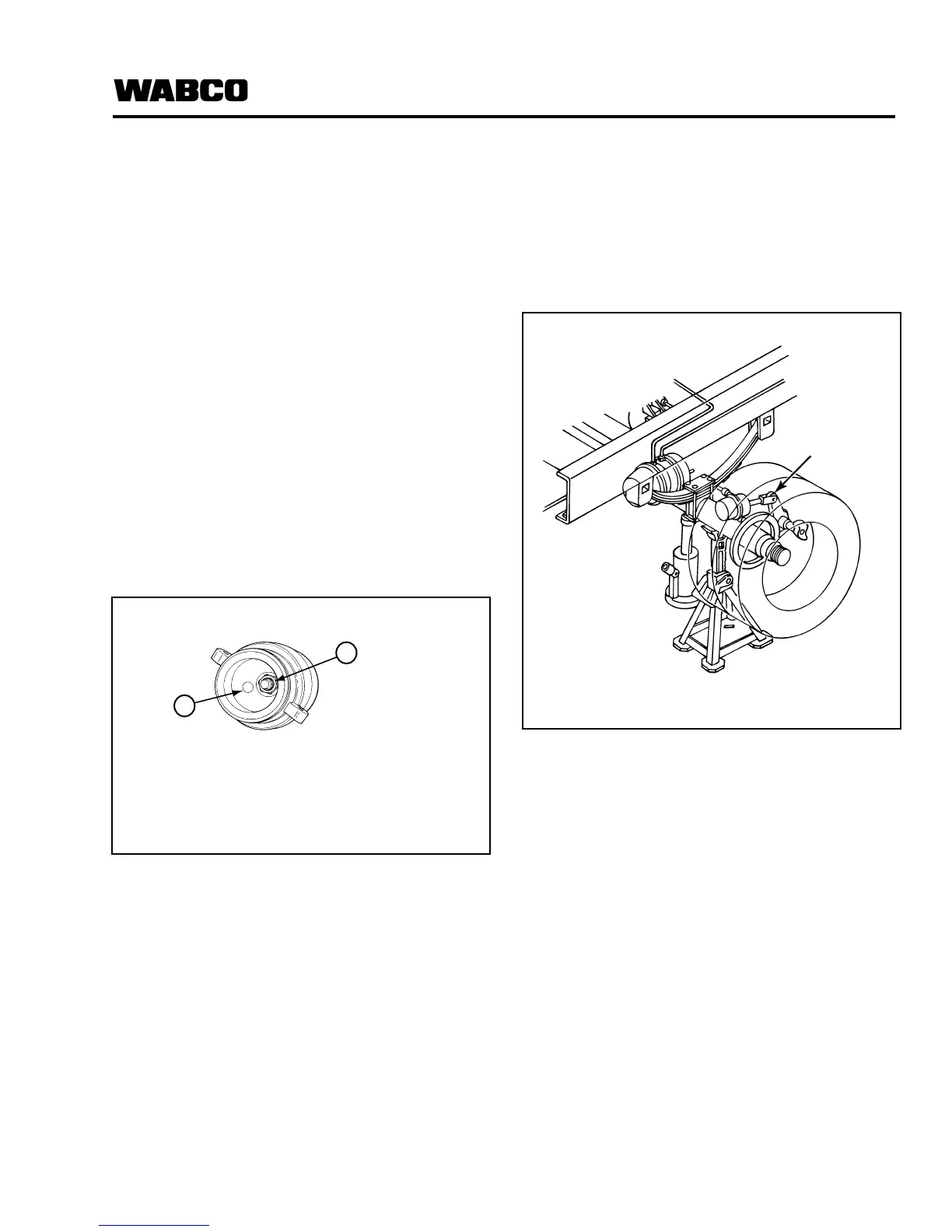

6. Rotate each sensed wheel — ONE AT A TIME —

at a rate of 1/2 revolution per second. Apply

control pressure to activate the brakes. Refer to

Figure 7.4 .

7. Observe the automatic slack adjuster on the

rotated wheel. It must move in and out as

the ABS valve cycles. This indicates a

proper installation.

앫 If the slack adjuster on the rotated wheel

does not move — but the slack adjuster on

the opposite wheel does move — the sensor

leads are reversed or the air line is plumbed

wrong. Correct the installation.

앫 If the slack adjuster on the rotated wheel

does not move, there may be a sensor gap

problem. Check the sensor gap and make

the necessary repairs.

8. Repeat Steps 6 and 7 on the remaining

sensed wheels.

9. If you installed a diagnostic blink code tool for

this test, remove it. Replace the protective cap

over the connector.

Figure 7.3

1 Blink Code Switch

2 LED Lamp

Figure 7.4

1 Slack Adjuster

Loading...

Loading...