Section 6

Component Replacement

Page 28

4. Install the wheel hub carefully, so that the

tooth wheel pushes against the sensor as you

adjust the wheel bearings. After installation

there should be no gap between the sensor

and the tooth wheel. During normal operation

a gap of 0.04-inch is allowable.

5. Sensor Output Voltage Test: Use a

Volt/Ohm meter to check the AC output voltage

of the sensors while rotating the wheel at

approximately one-half revolution per second.

Minimum output must be greater than

0.2 volts AC. If minimum output is less than

0.2 volts AC, push the sensor toward the tooth

wheel. Recheck the sensor output.

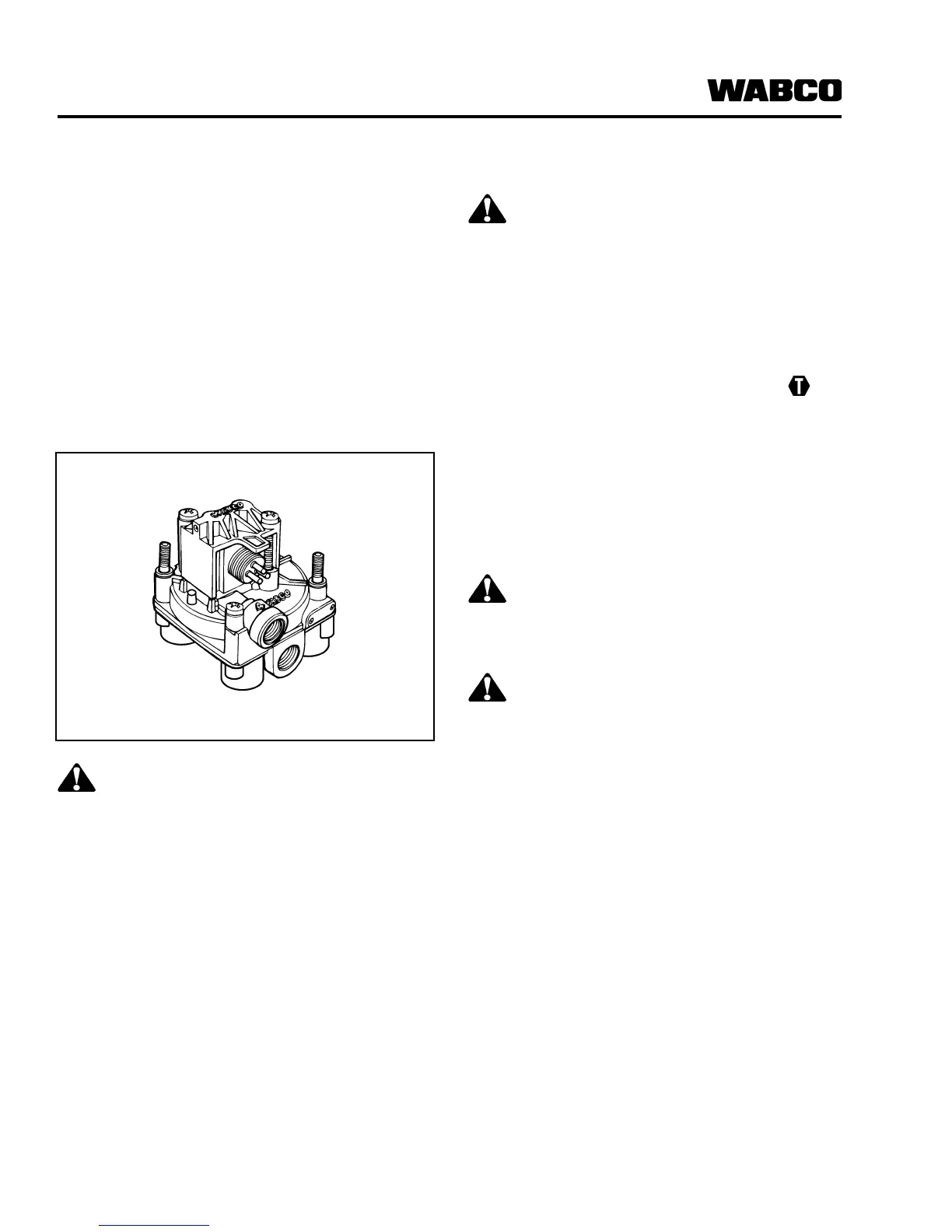

ABS Relay Valve

Release all pressure from the air system before

you disconnect any components. Pressurized air

can cause serious personal injury.

How to Remove a Standard ABS

Relay Valve

1. Release all pressure from the air system.

2. Disconnect the cable from the valve.

3. Attach labels to identify all of the air lines.

4. Disconnect the air lines from the valve.

5. Remove the mounting fasteners if the valve is

not nipple-mounted directly to the air tank.

6. Remove the valve.

How to Install a Standard ABS

Relay Valve

You must use Schedule 80 pipe nipple (3/4-inch

NPT) to nipple-mount the ABS relay valve securely

to the reinforced air tank to avoid possible serious

personal injury and damage to components.

1. Install the valve with two lock nuts and

washers as required. Tighten the hex nuts to

a torque of 18 lb-ft (24 N폷m) or nipple-mount

the valve directly to the air tank with

Schedule 80 pipe nipple (3/4-inch NPT).

2. Connect the air lines to the ports according

to the labels installed when the air lines

were disconnected.

3. Connect the cable to the valve.

4. Pressurize the brake system. Apply the brakes

and verify there are no air leaks.

The ECU/Valve Assembly

Release all pressure from the air system before

you disconnect any components. Pressurized air

can cause serious personal injury.

The ECU and valve assembly are sealed together

as one unit. To ensure product integrity and avoid

possible damage to the components, do not

attempt to separate the ECU from the valve.

How to Remove the

ECU/Valve Assembly

1. Release all pressure from the air system.

2. Attach labels to identify all air lines.

3. Disconnect the air lines from the

ECU/Valve Assembly.

4. Disconnect the power cable, diagnostic cable,

additional relay valve cable (if used), and all

sensor cables from the ECU/Valve Assembly.

Refer to Figure 6.4 .

5. Remove the ECU/Valve Assembly from its

mounting location:

a. Bracket-mounted: Loosen and remove the

two mounting bolts and lock nuts that hold

the assembly to the mounting bracket.

Remove the assembly.

b. Nipple-mounted to Air Tank: Unscrew the

assembly from the air tank.

Figure 6.3

Loading...

Loading...