31

8. Startup and Maintenance

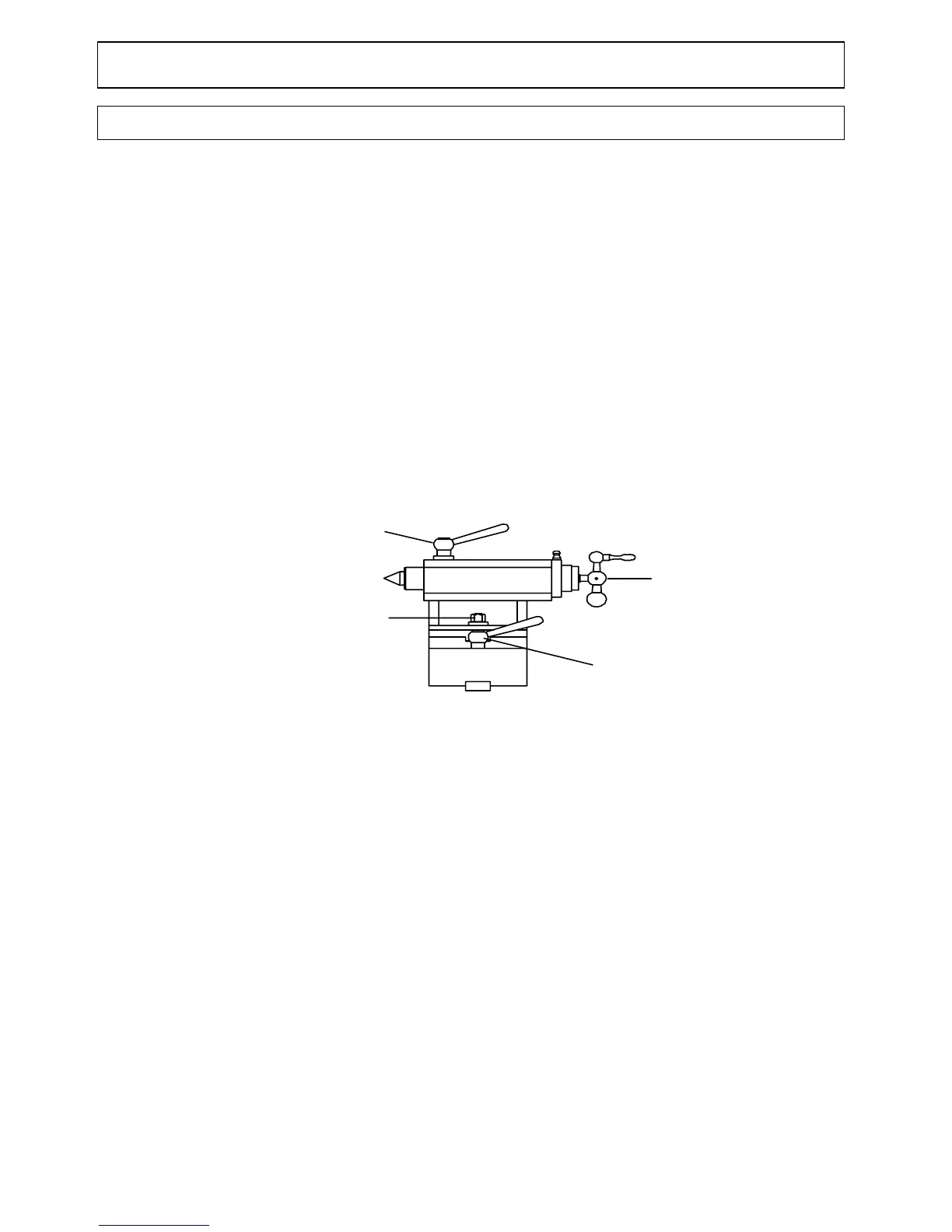

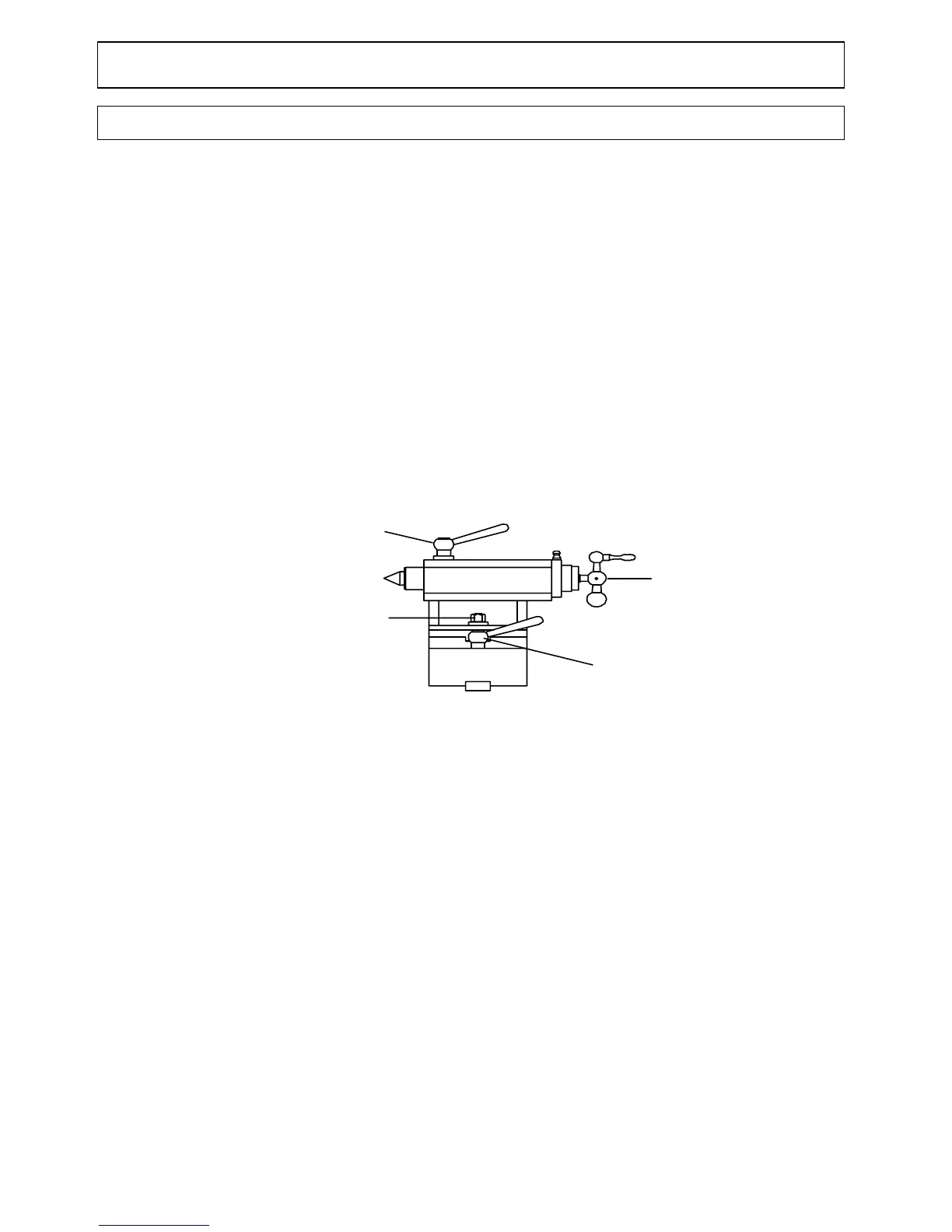

8.8 Tailstock

The tailstock is attached to the slide bars in such a way that it is slidable. It can be easily tightened

in any position by screwing the lower T-handle (4251). It can be separated into barrel and base. By

loosening the spanner bolt (424), the tailstock barrel can be pushed to either side by up to 10 mm

and is, therefore, suitable for the turning of slight tapers. After completing the taper work, the

tailstock is to be returned to its original position.

The central position of the tailstock is indicated by the mark on the side. By making a trial turning

operation establish whether the working piece is cylindrical and if necessary correct the position of

the tailstock.

Solid tailstock sleeve:

The solid tailstock sleeve, which is provided with a millimetre scale, is designed in such a way that

the lathe centre, drill barrel or chuck are automatically ejected when turning back.

Tool clamping:

An inner cone MT 2 which is worked into the tailstock sleeve serves to accept the tools. By

screwing the upper T-handle (4251), the tailstock sleeve can easily be clamped in any position. The

tailstock sleeve can be moved axialy over a threaded spindle by using the crank (31212) located at

the rear end.

spanner bolt (424)

T-handle (4251)

T-handle (4251)

crank (31212)

to move the tailstock sleeve

for tightening the tailstock

for tightening the

tailstock

Loading...

Loading...