38

10

.

Applications

10.2.3 Altering the feeds or thread pitches for D2000 E and D2400 E

2. Changing the feed from 0,085 mm to a metric pitch of 1,5 mm

a. - c. Start the procedure exactly as already described under pos. 1, a-c, expect for the hexagonal

nut being removed as well from the shearing bushing C, as described under pos. 1 b.

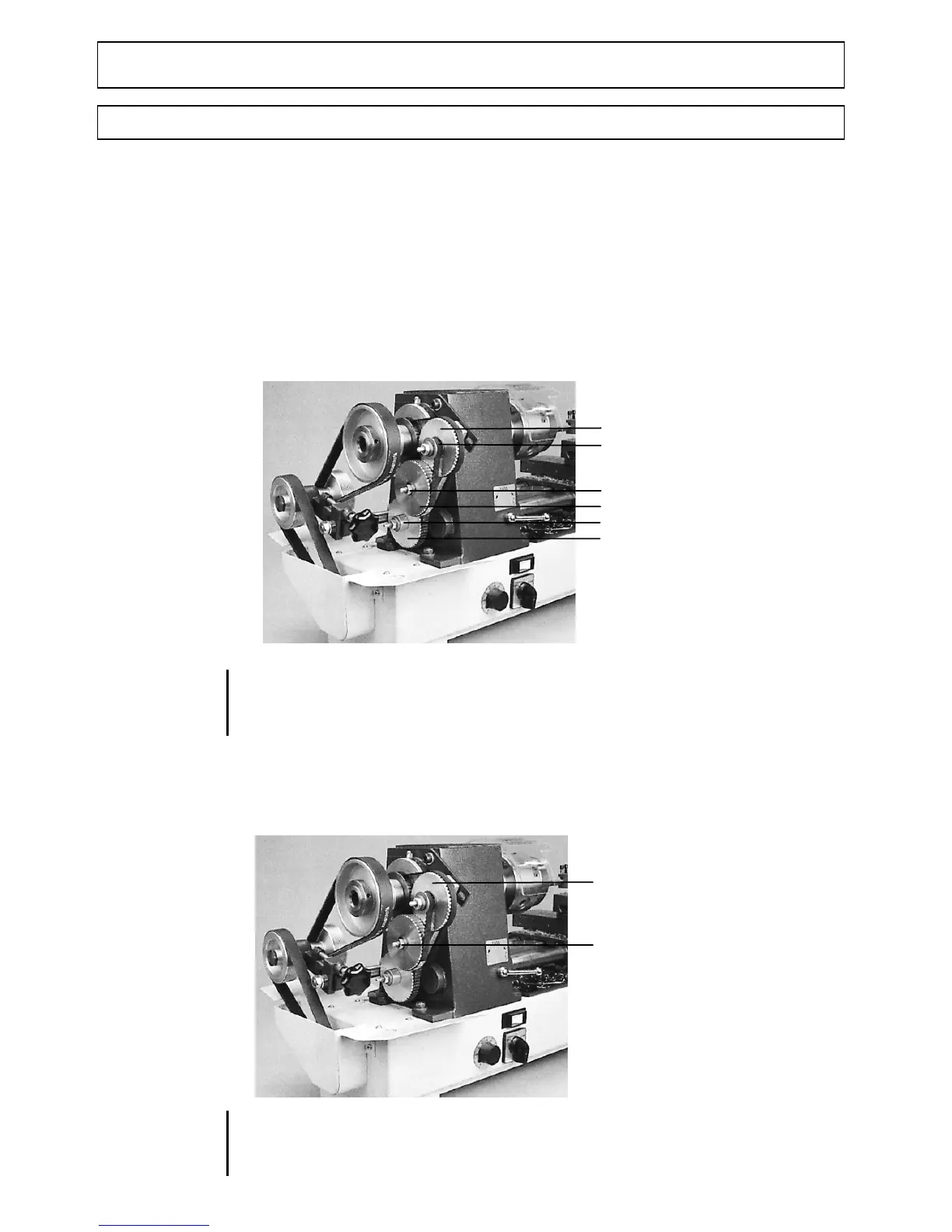

d. Pull off the bushing and the tooth belt Z 48 from the shearing bushing C. Put the bushing and

the tooth belt pulley Z 24 onto the shearing bushing but, make sure that the bushing

precedes the tooth belt pulley. Bolt B with toothed belt will not be needed with thread

cutting!

e. Pull off tooth belt pulley Z 14 from bolt A and put on tooth belt pulley Z 36. Put on toothed belt

connecting the main spindle with bolt A and from A to C.

f. - g. Proceed as described under pos. 1, f-g!

Z 14

bolt B escape

Z 48

Z 48

C

Z 48

i

Only the two short toothed belts (1145) are required for cutting metric threads.

The slightely longer toothed belt (1146), which connects the main spindle with

wheel A The toothed belt (1145) connects wheel B with wheel C.

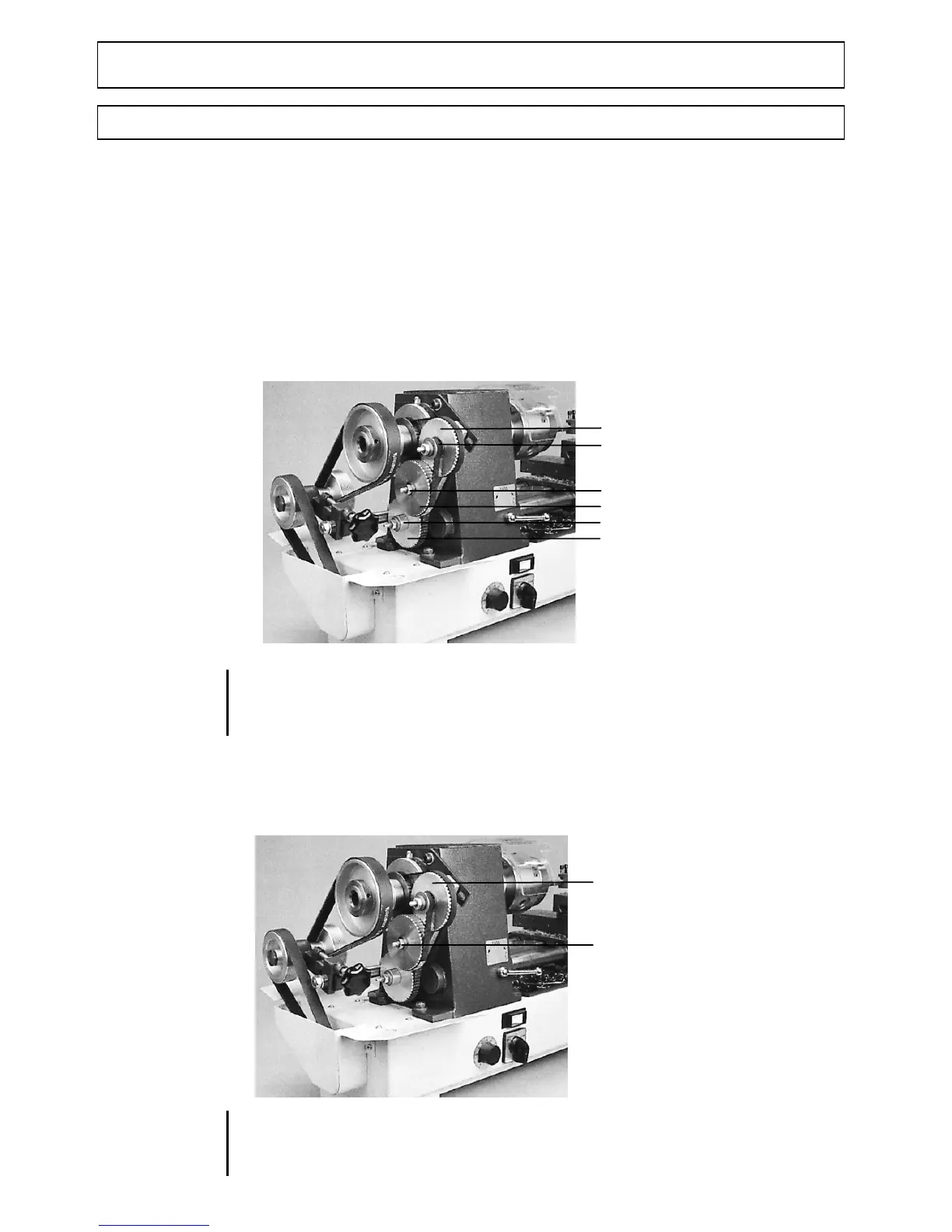

3. Changing the feed from 0,085 mm to thread pitch 12 threads/"

Proceed exactly as already described under pos. 2. The procedure differs merely in

additionally changing the tooth belt pulley Z 48 running on bolt A for the tooth belt pulley Z 34.

bolt B escape

to change Z 48 against Z 34

i

As when cutting metric threads, only the two shorter toothed belts (1145) are

normally required. Exeption: For a lead of 13. 14. 16 or 19 threads/inch. In this

case, the longer toothed belt (1146) is required to connect wheels A and C.

Loading...

Loading...