G 50 Maintenance

wc_tx001050gb.fm 75

7 Maintenance

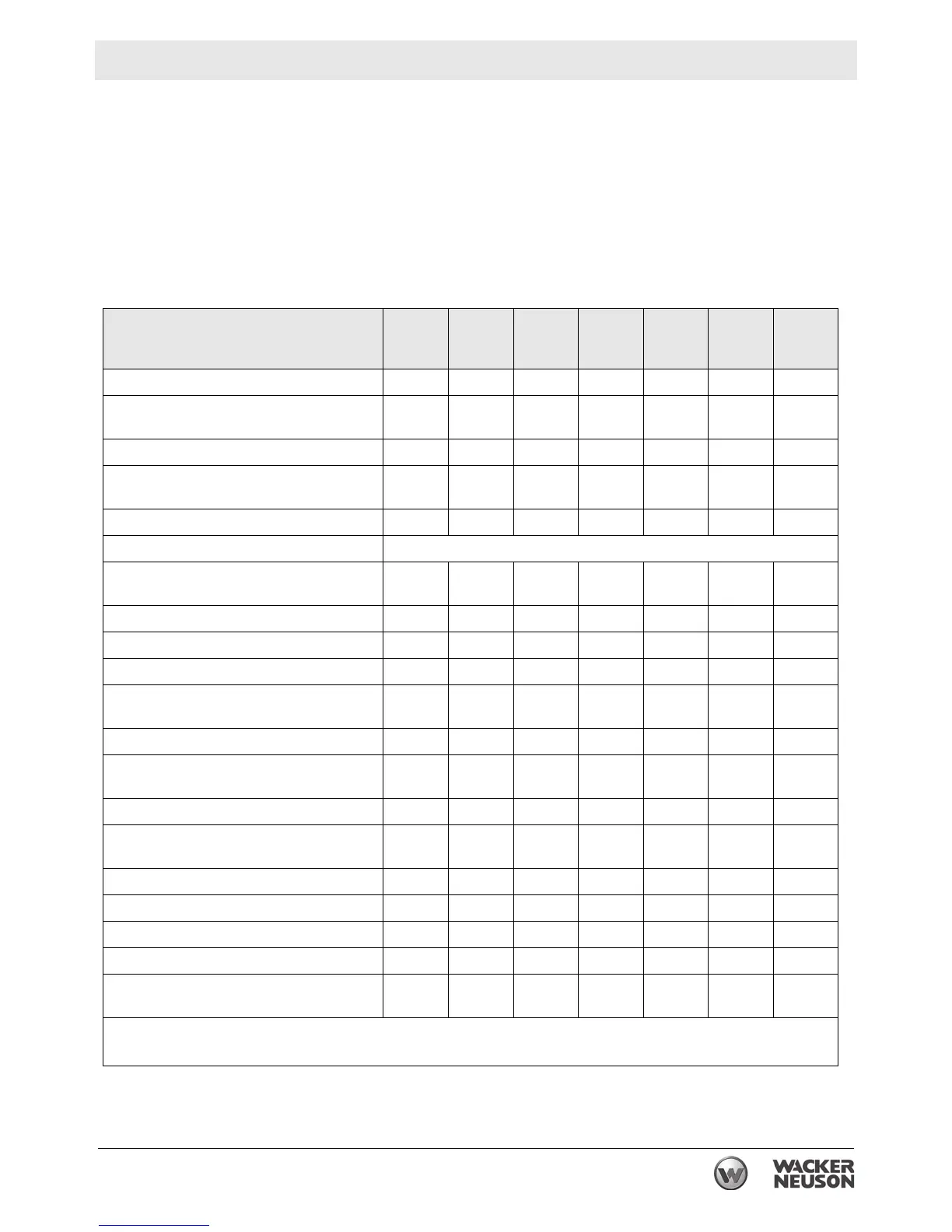

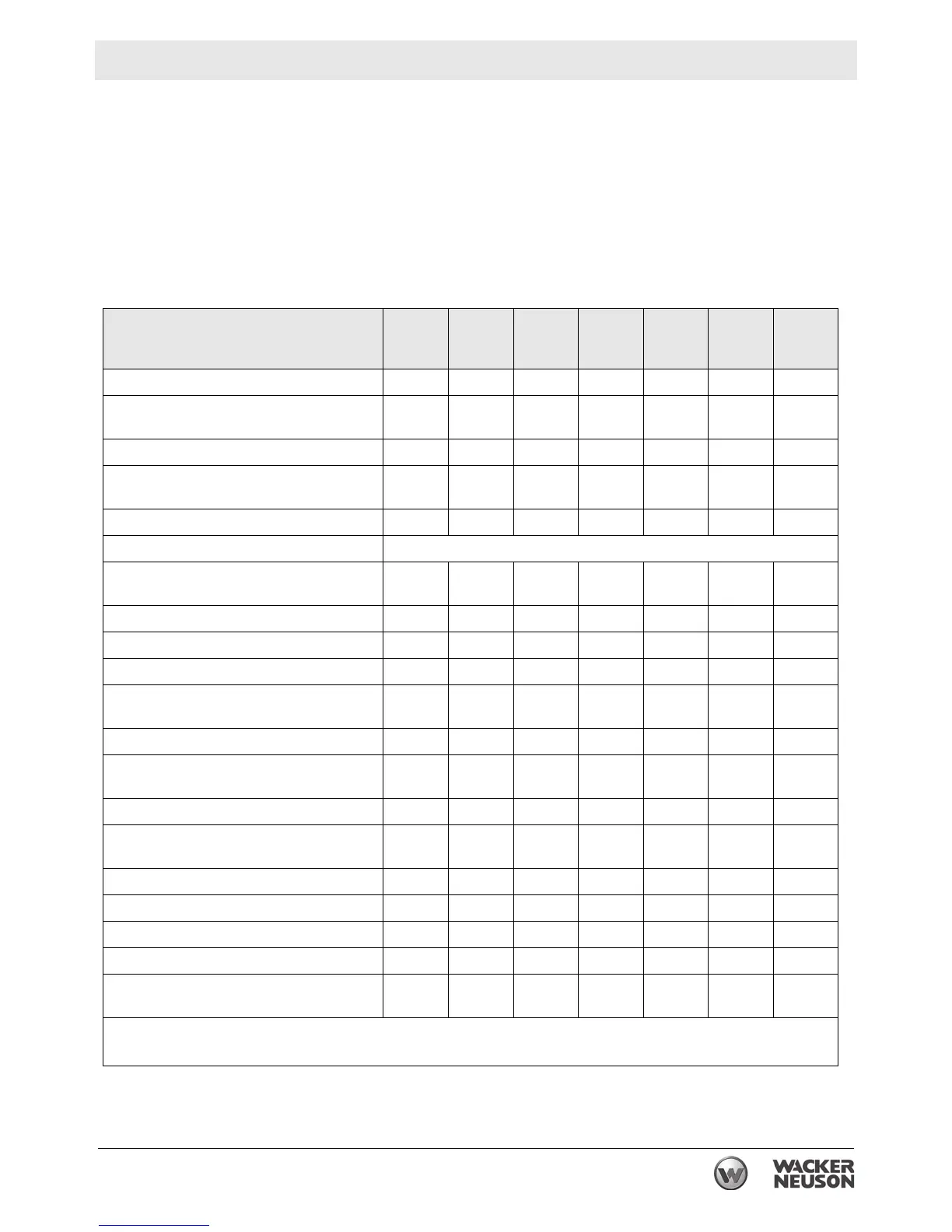

7.1 Periodic Maintenance Schedule

The table below lists basic machine and engine maintenance. Tasks

designated with check marks may be performed by the operator.

Tasks designated with square bullet points require special training

and equipment.

Refer to the engine owner’s manual for additional information.

Daily

Monthly

250 Hrs 600 Hrs

or

12 Mo

1200

Hrs or

24 Mo

2000

Hrs

Other

Check engine oil and coolant level 3

Check engine air filter gauge & air cleaner

dust cap *

3

Visual walkaround inspection 3

Check tire inflation, tread wear and lug nuts

before towing

3

Check fuel filter 3

Drain containment system As needed

Check brake fluid level in trailer at least

monthly

Service the battery

Change engine oil and replace oil filter**

Clean unit inside and out

Check air intake hoses, connections, and

system

3

Replace fuel filter element

Check automatic belt tensioner and belt

wear

3

Check cooling system 3

Perform coolant solution analysis & add

SCA's

Grease axle

Pressure test cooling system

Flush cooling system***

Check and adjust engine valve clearance

Replace crankcase ventilation filter every

750 hours

*Replace the air filter cartridge when yellow indicator of the engine air filter gauge reaches the red line.

**Change the oil after the first 100 hours, then every 250 hours.

***If John Deere antifreeze is used, the flushing interval may be extended. See engine Operator’s Manual.

Loading...

Loading...