97

PXM

OPERATING AND ASSEMBLY MANUAL

VERSION 08/2015 ORDER NUMBER DOC2350372

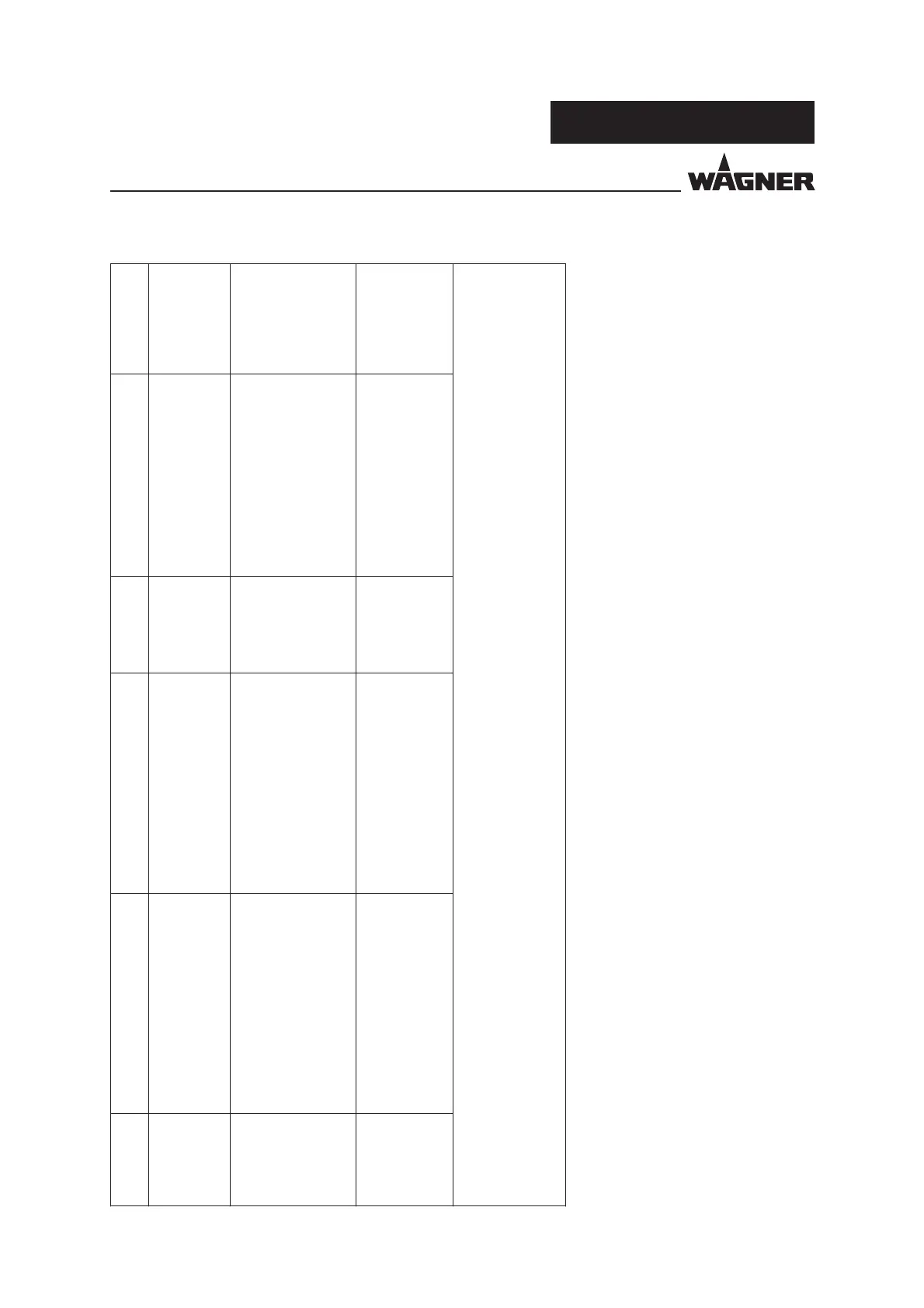

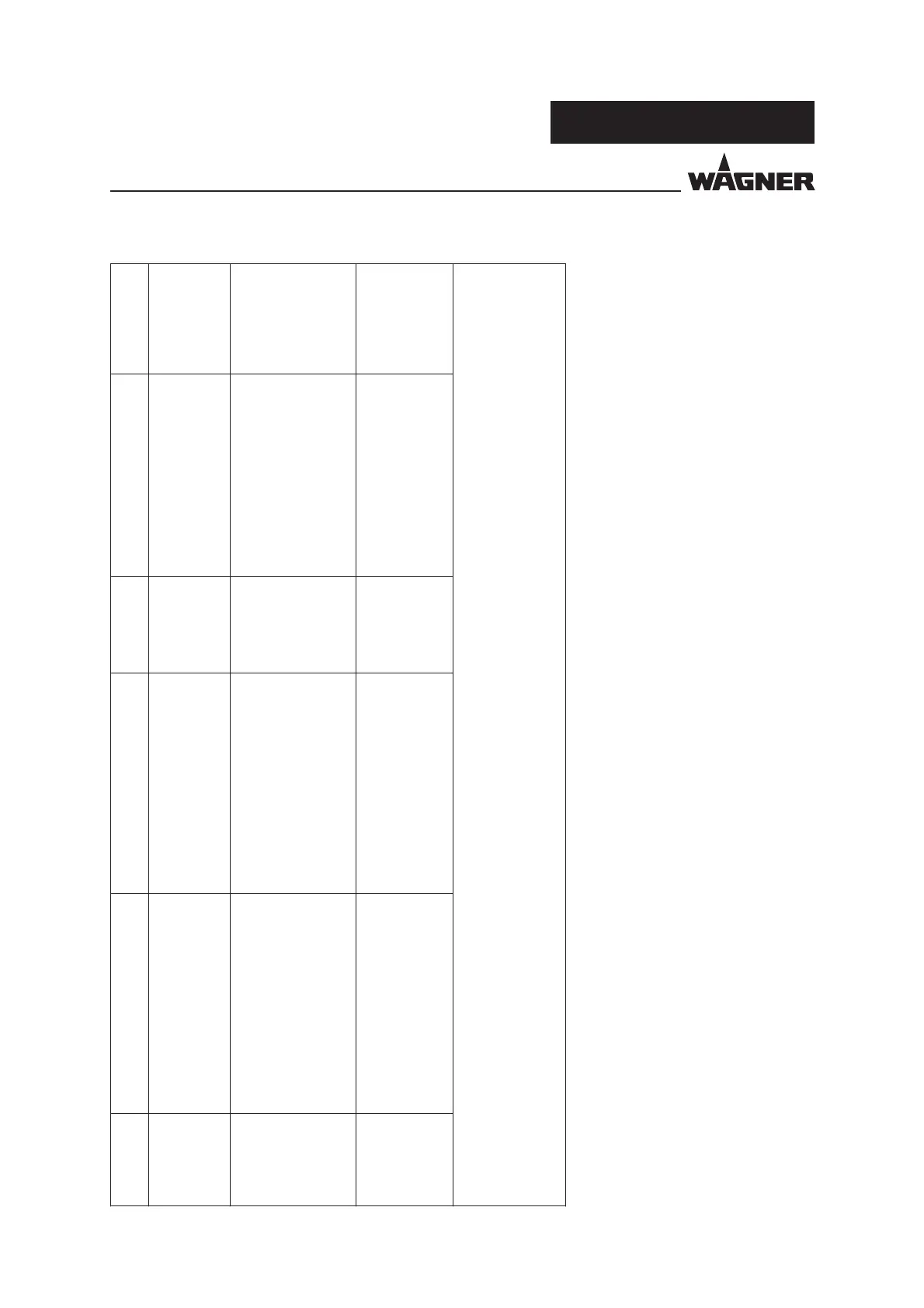

Section Type of inspection Requirements Inspection

by

Type of inspection Inspection

interval

1 Checking the e ectiveness of

technical ventilation

Checking the e ectiveness of

technical ventilation

TP/SP

ME

Measurements of air ow speed /

air quantities

Check the di erential pressure

indicator.

continuously

2 Link between technical ventilation

equipment and high-voltage,

compressed air and coating

material supply

The technical ventilation should be

interlocked such that the powder

feed and high-voltage cannot be

switched on, while the technical

ventilation is not working e ectively.

SP

FT

Test whether the system is safely

stopped and the product supply,

supply air and high-voltage are

switched o when the ventilation

is shut down.

annually

3 Parts carrying high-voltage outside

the spray area

Parts carrying high-voltage outside

the spray area must be routed such

that discharges which put people at

risk do not occur.

SP

FT

Inspect and test (e.g. by

measuring) whether all high-

voltage carrying parts do not

result in a discharge that puts

people at risk.

weekly

Legend:

MF = Manufacturer

ER = Employer

SP = Skilled person

FPO = Fire prevention o cer

ELT = Electrician

TP = Trained person

FT = Function test

ME = Measurement

OC = Organization check

VI = Visual inspection

CM = Constant monitoring

TT = Technical testing

Loading...

Loading...