50

Maintenance Instructions LUBRICATION

Check Transaxle Fluid Level

● The transaxle oil lubrication is SAE 20W50 (API

Service Class SL or higher) engine oil.

● Inspect both transaxle cases and hoses after

every 25 hours of operation for visible leaks.

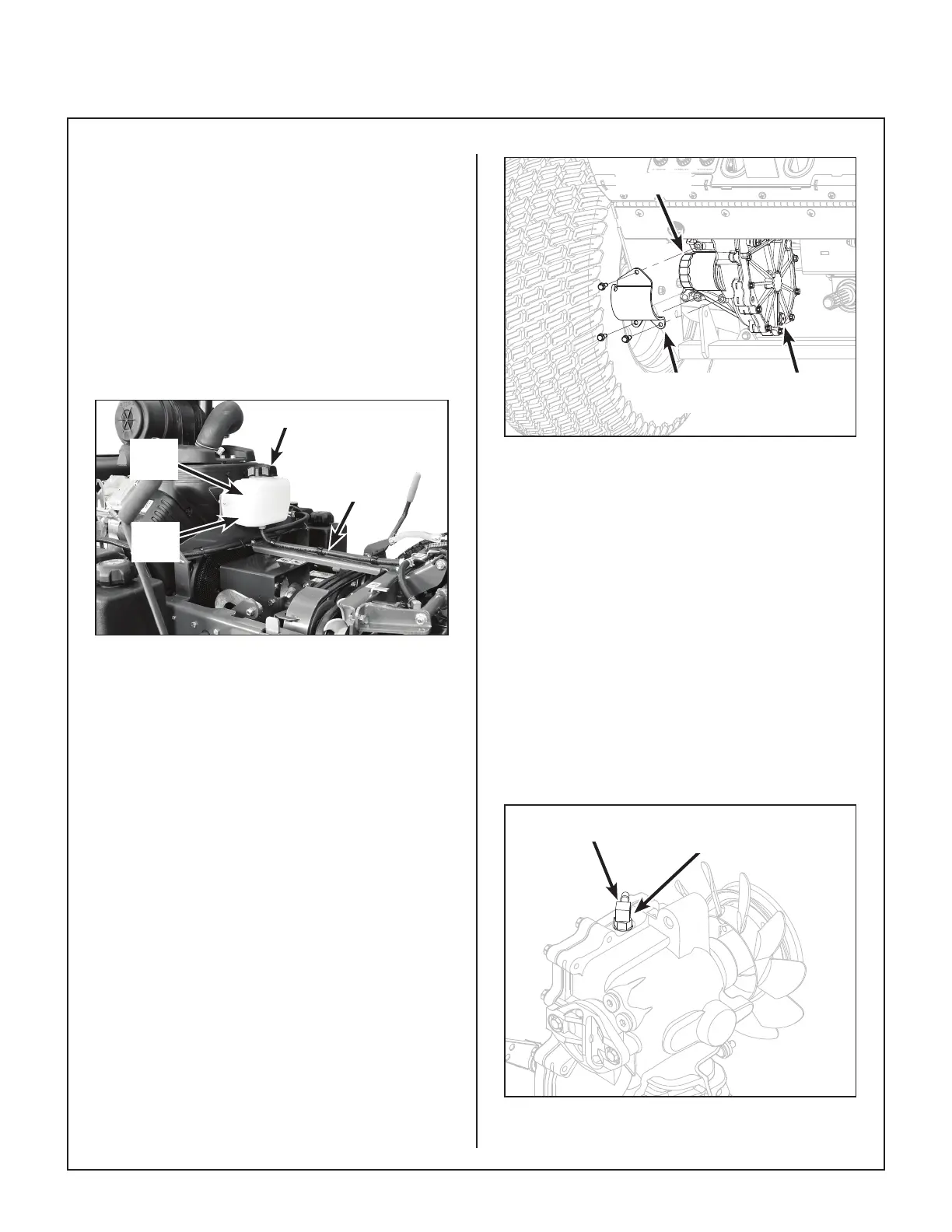

● The uid level of the transaxles can be checked

visually by looking at the uid level in the expan

sion reservoir. When the transaxles are cold, the

uid level in the expansion reservoir should be

between 1/4 and 1/2 in. (0.64 cm and 1.27 cm).

Hot

Level

Cold

Level

Hose to

Transaxles

Reservoir Cap

Expansion Reservoir Location

Transaxle Oil and Filter Change

Change the transaxle oil after the initial break-in

period of 75-100 hours. Thereafter, change oil ev-

ery 400 hours of operation as follows:

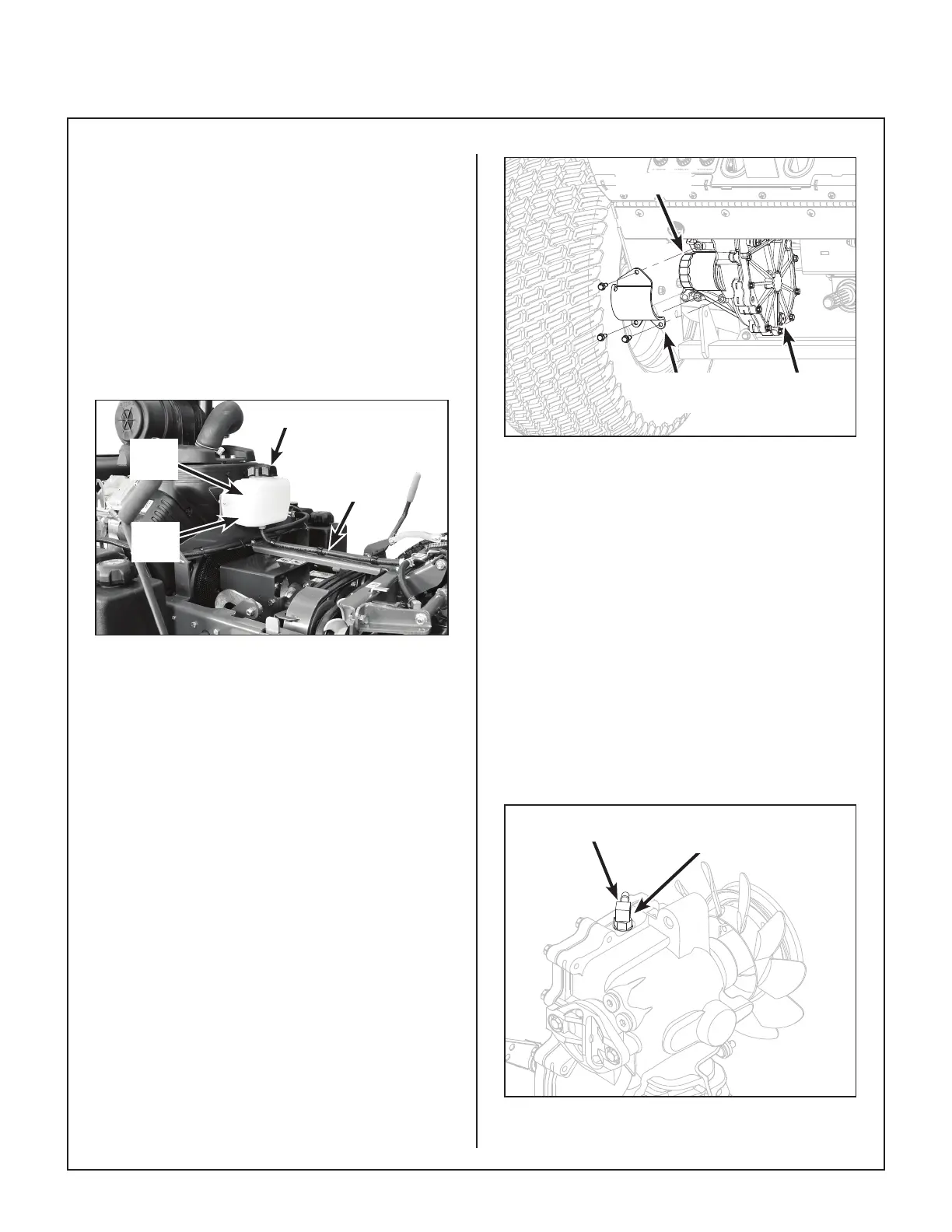

1. Thoroughly clean the exterior of the transaxle

housing before servicing. Remove expansion

reservoir cap to allow venting. Using a 1/4 in.

hex wrench, remove the plug on the lower in

side of each transaxle allowing the oil to drain.

2. Remove the oil lter guard, remove and replace

the oil lter using an oil lter wrench. Tighten

lter by turning lter 3/4 to 1 turn after gasket

contacts the lter base surface. Reinstall the oil

lter guard. (Refer to Transaxle Oil Drain

Plug, Filter, and Guard Location illustration.)

Oil Filter

Oil Filter

Guard

Oil Drain

Plug

Transaxle Oil Drain Plug, Filter, and

Guard Location

(Shown with Deck Support Arms

Removed for Clarity)

3. Reinstall drain plugs.

4. Remove the oil reservoir hose attached to the

elbow on top of the transaxles. Remove the

elbows to access the oil ll opening.

5. Fill the transaxles with 20W50 (API Service

Class SL or higher) oil through the opening

(where the elbows were). Fill up to the opening.

6. Before reinstalling the elbows, screw the lock

ing nut on the elbows down until they are snug

(the oring on the elbow will be to the bottom of

the oring groove).

Elbow

Screw Locking

Nut Down

Reinstall Transaxle Elbows

Loading...

Loading...