4.4 Overhaul inter vals and expected life times

The following overhaul intervals and lifetimes are for guidance only. Achievable lifetimes depend

on operating conditions, average loading of the engine, fuel quality used, fuel handling system,

performance of maintenance etc.

Expected lifetime is different depending on fuel used. For detailed information on fuel qualities,

please see Table Heavy fuel oils.

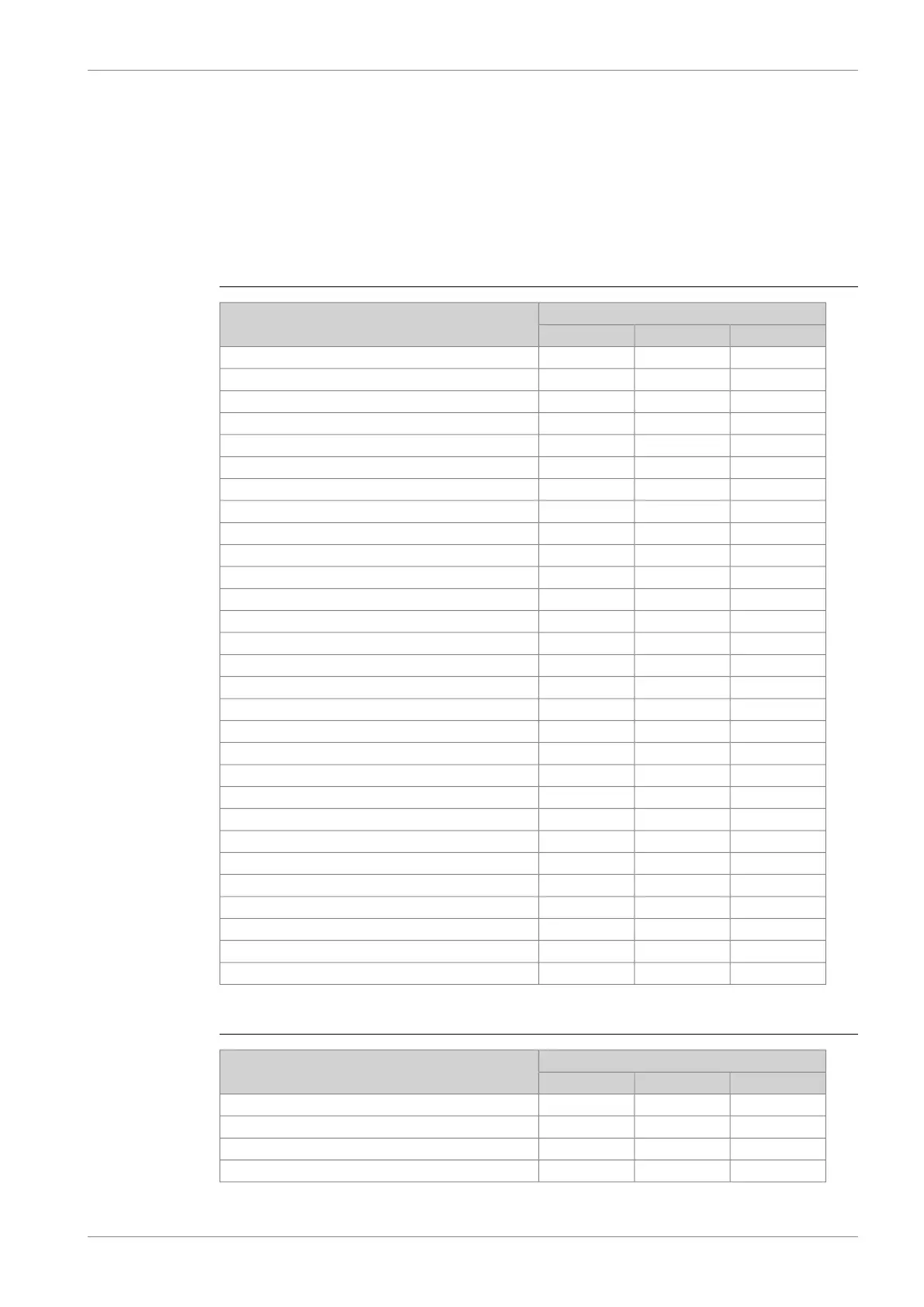

Table 4-1 Time between Overhaul

Time between inspection or overhaul (h)Component

HFO2 operationHFO1 operationLFO operation

Twin pump fuel injection

- Injection nozzle

120001200012000- Injection pump element

120001600020000Cylinder head

- Inlet valve seat

- Inlet valve, guide and rotator

- Exhaust valve seat

- Exhaust valve, guide and rotator

Piston crown, including recondition

Piston skirt

120001600020000- Piston skirt/crown dismantling one

240002800032000- Piston skirt/crown dismantling all

Piston rings

120001600020000Cylinder liner

Antipolishing ring

120001600020000Gudgeon pin, inspection

120001600020000Gudgeon pin bearing, inspection

Big end bearing

120001600020000- Big end bearing, inspection of one

360003600036000- Big end bearing, replacement of all

Main bearing

120001600020000- Main bearing, inspection of one

360003600036000- Main bearing, replacement of all

Camshaft bearing

360003600036000- Camshaft bearing, inspection of one

600006000060000- Camshaft bearing, replacement of all

120001200012000Turbocharger inspection, cleaning

600060006000Charge air cooler

Rubber elements for flexible mounting

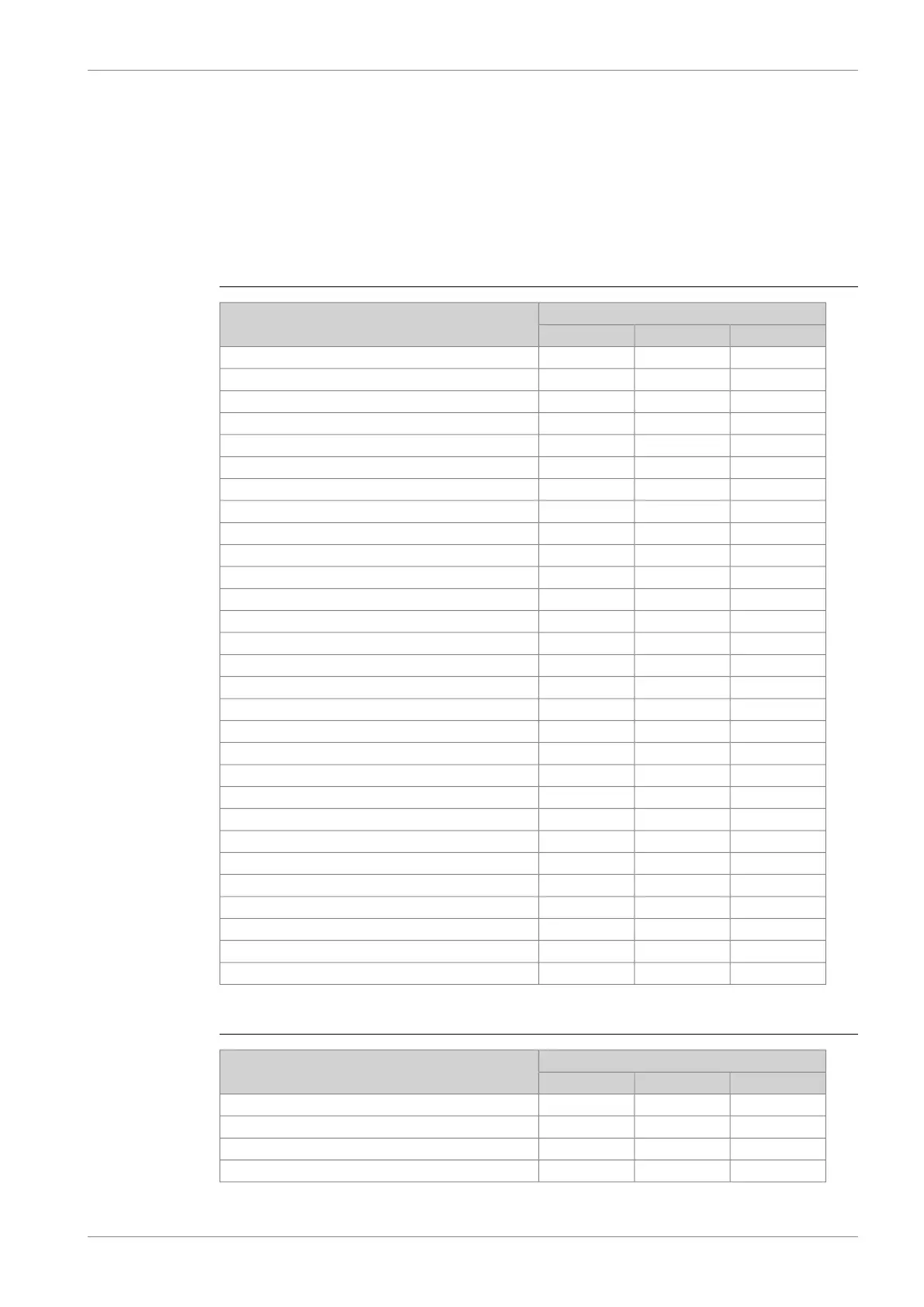

Table 4-2 Expected Life Time

Expected life time (h)Component

HFO2 operationHFO1 operationLFO operation

Twin pump fuel injection

600060006000- Injection nozzle

240002400024000- Injection pump element

600006000060000Cylinder head

DAAB605814 4-7

4. Description of the EngineWärtsilä 46F Product Guide

Loading...

Loading...