Pitch

the horizontal run

of the

flue

pipe

upward 1/4 inch

(6.35mm) per

foot

(.305m)

or more. Run directly

to the

chimney, fasten

joints

securely and

support horizontal

runs

to

prevent

sagging.

lf the

flue

pipe

must be

extra

long,

it's

size should be

increased. The

horizontal length

of the flue

pipe

should

not

exceed the height

of the chimney

above the flue

connection.

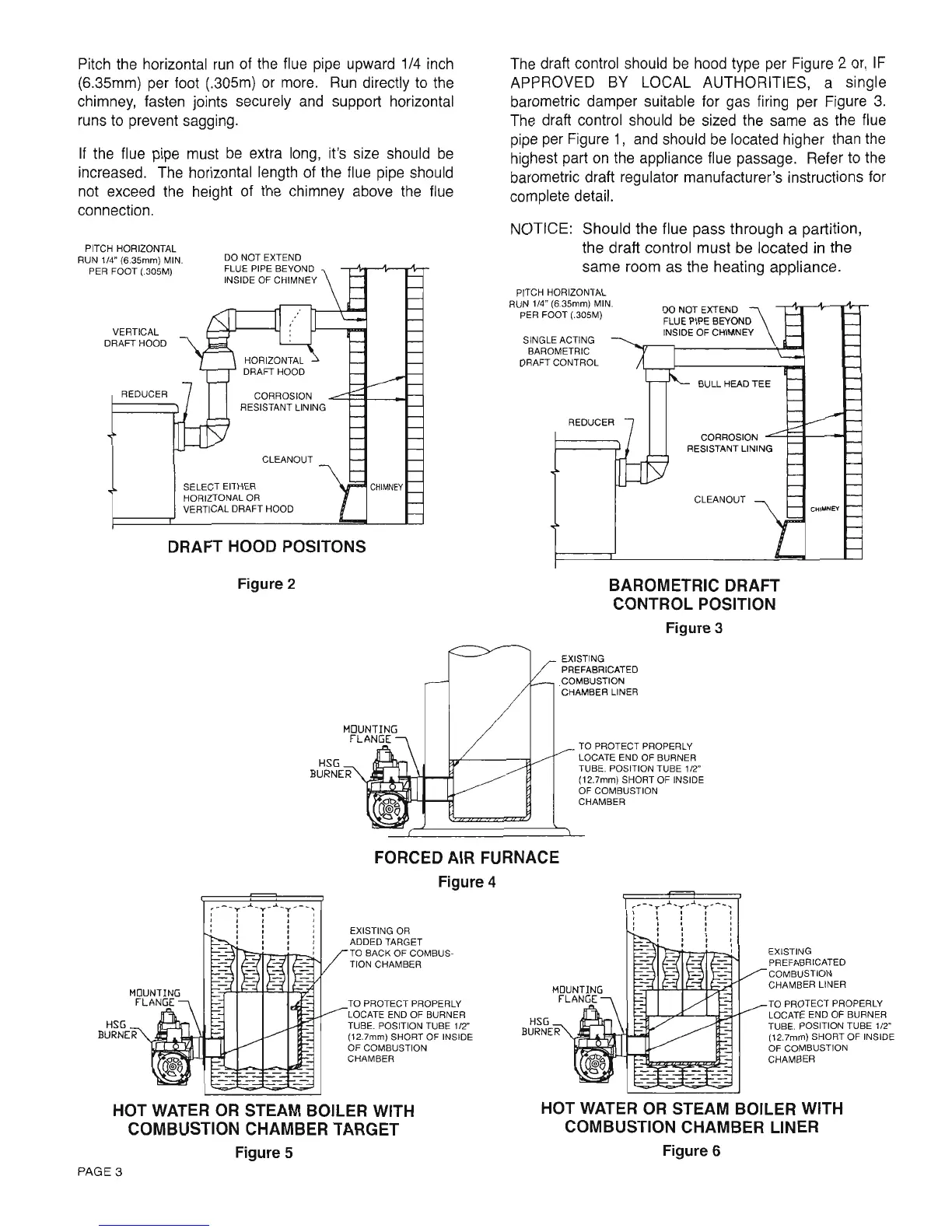

PITCH

HOBIZONTAL

RUN

1/4"

(6.35mm)

MlN.

PER FOOT

(.gosM)

VERTICAL

DRAFT HOOD

Figure

2

HSG

-

BURNER

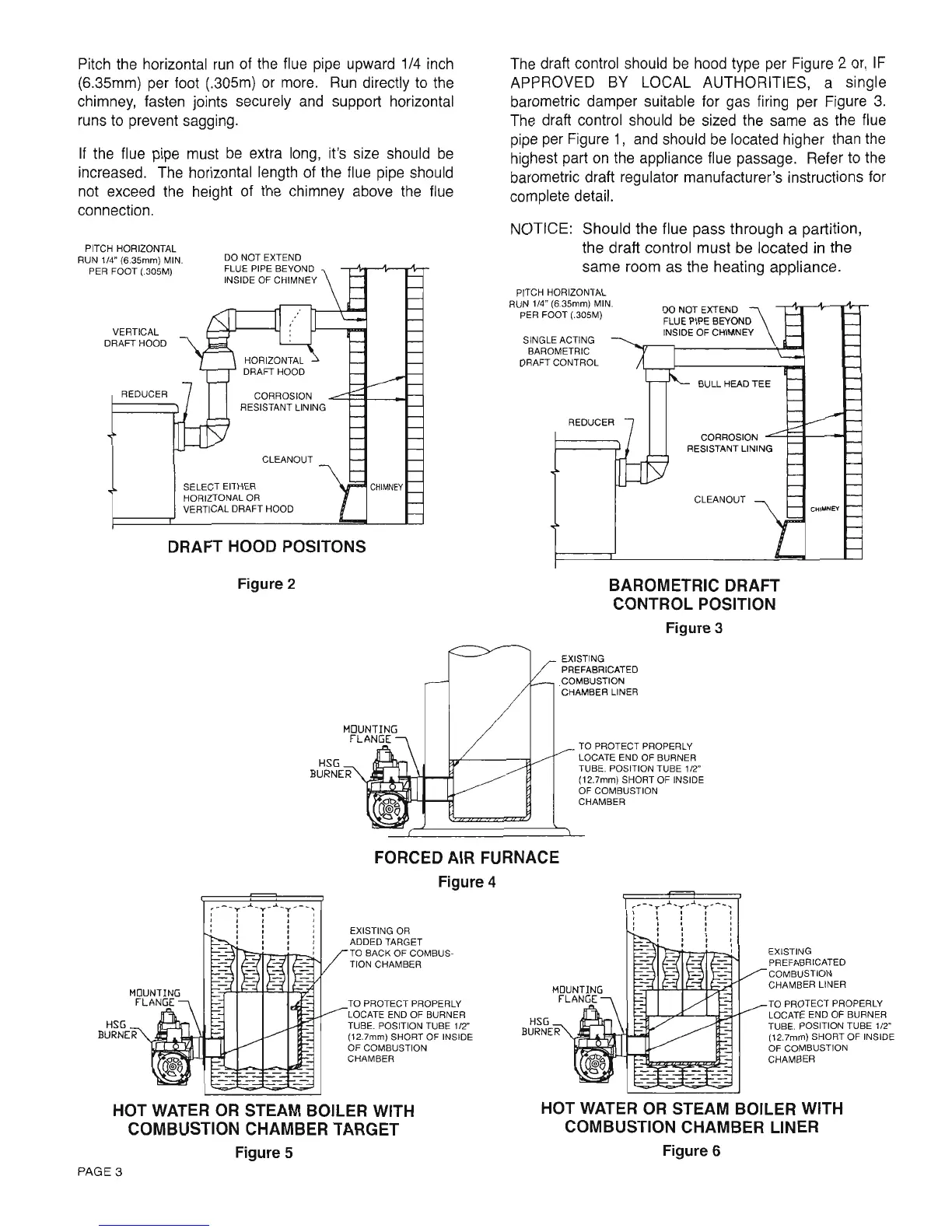

The

draft control

should be

hood

type

per

Figure

2 or,lF

APPROVED

BY LOCAL AUTHORITIES,

a single

barometric damper

suitable

for

gas

firing

per

Figure

3.

The

draft control

should be sized the

same as the

flue

pipe

per

Figure 1,

and should be located higher

than the

highest

part

on the appliance flue

passage.

Refer

to the

barometric draft regulator manufacturer's

instructions for

complete detail.

NOTICE:

Should the flue

pass

through a

partition,

the draft control must

be

located

in the

same

room

as

the

heating

appliance.

PITCH HORIZONTAL

BUN 1/4"

(6.3smm)

MlN.

PEF FOOT

(.3osrV)

DO NOT EXTEND

FLUE PIPE

BEYONO

INSIDE

OF CHIMNEY

SINGLE

ACTING

BAROMETRIC

DRAFT CONTROL

BAROMETRIC

DRAFT

CONTROL POSITION

Figure

3

EXISTING

PREFABRICATEO

COMBUSTION

CHAMBEB

LINER

TO PROTECT PROPERLY

LOCATE END OF BURNEF

TUBE. POSITION TUBE

1/2'

(12.7mm)

SHORT OF INSIDE

OF COMBUSTION

CHAMBEB

FORCED

AIR FURNACE

Figure

4

EXISTING

OR

ADDED TARGET

TO BACK

OF COMBUS-

TION

CHAMBER

TO PROTECT

PBOPERLY

LOCATE END

OF BURNER

TUBE. POSITION

TUBE 1/2'

(12.7mm)

SHORT OF INSIDE

OF COMBUSTION

CHAI\4BER

EXISTING

PREFABRICATEO

COMBUSTION

CHAIV]BEB LINEFI

TO PROTECT PROPERLY

LOCATE END

OF

BURNEF

TUBE. POSITION TUBE 1/2"

(12.7mm)

SHOBT OF INSIDE

OF COMBUSTION

CHAMBEF

HOT

WATER

OR STEAM BOILER

WITH

COMBUSTION

CHAMBER

TARGET

Figure

5

PAGE

3

HOT WATER

OR STEAM BOILER

WITH

COMBUSTION

CHAMBER LINER

COFFOSION

RESISTANT

LINING

CLEANOUT

SELECT EITHER

HORIZTONAL

OR

VEFTICAL

DBAFT HOOD

DRAFT

HOOD POSITONS

Figure 6

Pitch

the

horizontal

run

of

the

flue

pipe

upward

1/4

inch

(6.35mm) per foot (.305m)

or

more.

Run

directly

to

the

chimney, fasten joints securely

and

support horizontal

runs

to

prevent sagging.

If

the flue pipe must

be

extra

long,

it's size should

be

increased. The horizontal length of the flue

pipe

should

not exceed

the

height of

the

chimney above

the

flue

connection.

CHI""NEY

CLEANOUT

BULL HEAD

TEE

CORROSION -=-+--1------'"

RESISTANT LINING

DO

NOT EXTEND

FLUE PIPE BEYOND

INSIDE OF CHIMNEY

SINGLE ACTING

BAROMETRIC

DRAFT CONTROL

The draft control should

be

hood type per Figure 2

or,

IF

APPROVED

BY

LOCAL AUTHORITIES, a single

barometric damper suitable for gas firing per Figure

3.

The

draft control should

be

sized the same

as

the flue

pipe

per Figure

1,

and

should

be

located higher than

the

highest part

on

the

appliance flue passage. Refer

to

the

barometric draft regulator manufacturer's instructions for

complete detail.

NOTICE: Should the flue pass through a partition,

the draft control must be located

in

the

same room as the heating appliance.

PITCH HORIZONTAL

RUN 1/4" (6.35mm) MIN.

PER FOOT (.305M)

CHIMNEY

CORROSION

RESISTANT LINING

CLEANOUT

DO NOT EXTEND

FLUE PIPE BEYOND

INSIDE

OF

CHIMNEY

SELECT EITHER

HORIZTONAL OR

VERTICAL DRAFT HOOD

DRAFT HOOD POSITONS

REDUCER

VERTICAL

DRAFT HOOD

PITCH HORIZONTAL

RUN 1/4" (6.35mm) MIN.

PER FOOT (.305M)

Figure 2

BAROMETRIC DRAFT

CONTROL POSITION

Figure 3

EXISTING

PREFABRICATED

COMBUSTION

CHAMBER LINER

HSG

BURNER

TO PROTECT PROPERLY

LOCATE END OF BURNER

TUBE. POSITION TUBE

112"

(12.7mm) SHORT OF INSIDE

OF COMBUSTION

CHAMBER

FORCED AIR FURNACE

Figure 4

HOT WATER

OR

STEAM BOILER WITH

COMBUSTION CHAMBER LINER

Figure 6

EXISTING

PREFABRICATED

COMBUSTION

CHAMBER LINER

TO PROTECT PROPERLY

LOCATE END OF BURNER

TUBE. POSITION TUBE 1/2"

(12.7mm) SHORT OF INSIDE

OF

COMBUSTION

CHAMBER

,,_

...

y

..

..l

..

.,.. .. .J.

...

y

..

__

, , ,

. , ,

,

, ,

. , ,

, , ,

, . ,

. ,

HSG

BURNER

EXISTING OR

ADDED TARGET

TO BACK OF COMBUS·

TION CHAMBER

TO PROTECT PROPERLY

LOCATE END OF BURNER

TUBE. POSITION TUBE 1/2"

(12.7mm) SHORT OF INSIDE

OF COMBUSTION

CHAMBER

HOT WATER OR STEAM BOILER WITH

COMBUSTION CHAMBER TARGET

Figure 5

PAGE 3

Loading...

Loading...