E.

COMBUSTION

CHAMBER

A combustion chamber

is normally

required to

protect

non-heat

transfer surfaces, and to

provide

a

radiant

bed

for rapid heat transfer

to the

primary

surfaces of the

heat

exchanger.

lf in

good

condition,

the existing combustion chamber can be used.

Afull

combustion chamber

liner is recommended for

warm air

furnaces,

(see

Figure 4),

and a target

wall

or

full

combustion chamber liner is recommended

for wet leg cast

iron

or steel boilers.

(See

Figures 5

and 6). lf a built-up chamber is necessary, use

2300'

F

(1260"C)

minimum insulating fire-brick or

fiberfrax.

THE BURNER

AIR TUBE MUST

NOT BE

ALLOWED TO EXTEND INTO THE

CHAMBER

PROPER; lT MUST BE

SET

1/2 INCH

(12.7mm1

SHORT

OF

THE INSIDE SURFACE.

Before

permanently

securing the burner to the

heating appliance

with

either the adjustable mounting

flange or

pedestal

or cementing around the air tube

in the combustion chamber opening,

check

that the

burner

head

assembly

is free

of

foreign

materials and

that the

sensor

and electrode

probes

have not been

damaged or

repositioned,

see

Figure 13.

RECOMMENDED

COMBUSTION

CHAMBER SIZES

Figure 7

SUPPLY

LINE

CONNECTION

TO

BURNER

F.

GAS

PIPING

NOTICE:

All

piping

must comply

with

state

and/or

local

codes.

The

available

gas

supply

pressure

should

be within minimum and maximum

pressures

shown

in

the burner specifications.

lf

the

gas

supply

pressure

exceeds the 14"

W.C.

(3.5

k Pa)

maximum,

an

intermediate main

gas

regulator must

be installed

ahead of the main

gas

manual

shut

off valve

shown

in Figure 8.

WARNING: Failure

to

install

the

intermediate

gas

regulator will result in

gas

leakage from burner

gas

valve.

A drip leg

or sediment

trap must be installed in the

supply

line

to the burner. See

Figure

8.

A

pipe

union

shall be

installed in the

gas

line

adjacent to, and upstream from, the main

gas

manual

shutoff

valve,

See

Figure

8.

The

gas

supply

piping

to the burner

should

branch

off

from the main

gas

supply

line

as close to the

gas

meter as

possible.

Do not

connect to the bottom of

a

horizontal

section. See

Figure

9

for

gas

supply

pipe

sizes.

Use

new black iron

pipe

and malleable fittings free

of burrs and defects. Use

pipe

joint

compound

resistant to liquefied

petroleum gases.

A118"

(3.175mm)

NPT

plugged

tapping accessible

for test

gauge

connection shall be

provided

immediately upstream of the

gas

supply connection

for

determining

gas

supply

pressure

to the burner.

Test new

supply

piping

for leaks. CAUTION:

DURING PRESSURE TEST FOR LEAKS IN GAS

SUPPLY

PIPING, THE BURNER MUST BE

DISCONNECTED

TO

PREVENT

EXPOSING THE

COMBINATION

GAS VALVE TO PRESSURES

OVER 112"

(3447

PaG)

PSIG. POSSIBLY

DAMAGING THE VALVE AND VOIDING THE

BURNER WARRANTY.

CAPACITIES

SHOWN

ARE FOR A TOTAL PRESSURE

DROP OF 0.3" W.C.

(74.73Pa)

FOR

0.5"

W.C.

(12a.55Pa)

PRESSURE DROP. MULTIPLY CAPACITY SHOWN

BY 1.3.

FOR HIGHER PERMISSIBLE

PRESSURE DROPS,

CONSULT

YOUR

UTILITY.

SUPPLY

PIPE

CAPACITIES

lN MBtu/HR

(kW)

INPUT

BTU/HR

kWHr

PREFERRED

wlu I H"{mm) x LLNU I H"(mm)ulAM."

(mm

50 MBtu/HH

(.|4.655kW)

7 n77 8\X7 t177 8\ 8

(203.2)

75 MBtu/HR

(219.825kW)

7 1/2

(190

5) X 7 1/2

(190.5)

9 {228.6)

100 MBtu/HR

(293.1kW)

12

(304.8)

X 12

(304.8)

1

3

(330.2)

150 MBtu/HR

(439

65kW)

12

(304.8)

X 15

(381)

14

(355

6)

200 MBtu/HR

(586.2kW)

13

(330.2)

X 17

(431.8)

15

(381

)

250 MBtu/HR fi32.75kW)

13

(330.2)

X

18

1457.2)

'16

(406.4)

300 MBtu/HR f879,3kW) 13

(330.2)

X 20

(508)

18

U57.2\

350 MBtu/HR

(1

025.85kW)

14

(355.6)

X 21

(533.4)

20

(508)

400 MBtu/HR {11i2.4kw) t5

(381)

X 22 {558.8) 21

(533.4)

PI PE

SIZE

TYPE

OF GAS

CAPACITY -

MBtu/HR

(kJ)

LENGTH OF PIPE

15

(381mm)

l0

(762mm)

15

(1143mm

)0

(2286mm

3t4

t19.05mm)

Propane 400

422000k.t.|

250

t263750k,

200

21 1

000kJ)

1

(25.4mm)

l\atu ral

Propane

4UU

422000kJ)

z5u

(263750kJ

400

ta220nok.l

ZUU

21 1

000kJ)

350

i6q25nk. t)

250

'26i750k.t\

1 1t4

(31.75mm)

Natural

Propane

400

(422000kJ)

400

422000kJ)

400

422000k.1\

300

31 6500kJ)

400

422000kJ)

1 1t2

l38.1mm)

Natural

400

arrnnnk.t\

Figure

8

Figure

9

PAGE 4

PAGE 4

E.

COMBUSTION CHAMBER

A combustion chamber is normally required to

protect non-heat transfer surfaces, and to provide a

radiant bed for rapid heat transfer to the primary

surfaces of the heat exchanger.

If

in

good condition,

the existing combustion chamber can be used.

A full combustion chamber liner is recommended for

warm air furnaces, (see Figure 4), and a target wall

or

full combustion chamber liner is recommended

for wet leg cast iron

or

steel boilers. (See Figures 5

and 6). If a built-up chamber is necessary, use

2300° F (1260°C) minimum insulating fire-brick

or

fiberfrax.

THE BURNER AIR TUBE MUST NOT

BE

ALLOWED TO EXTEND INTO THE CHAMBER

PROPER; IT MUST

BE

SET 1/2 INCH (12.7mm)

SHORT OF THE INSIDE SURFACE.

Before permanently securing the burner to the

heating appliance with either the adjustable mounting

flange

or

pedestal or cementing around the air tube

in

the combustion chamber opening, check that the

burner head assembly is free of foreign materials and

that the sensor and electrode probes have not been

damaged

or

repositioned, see Figure 13.

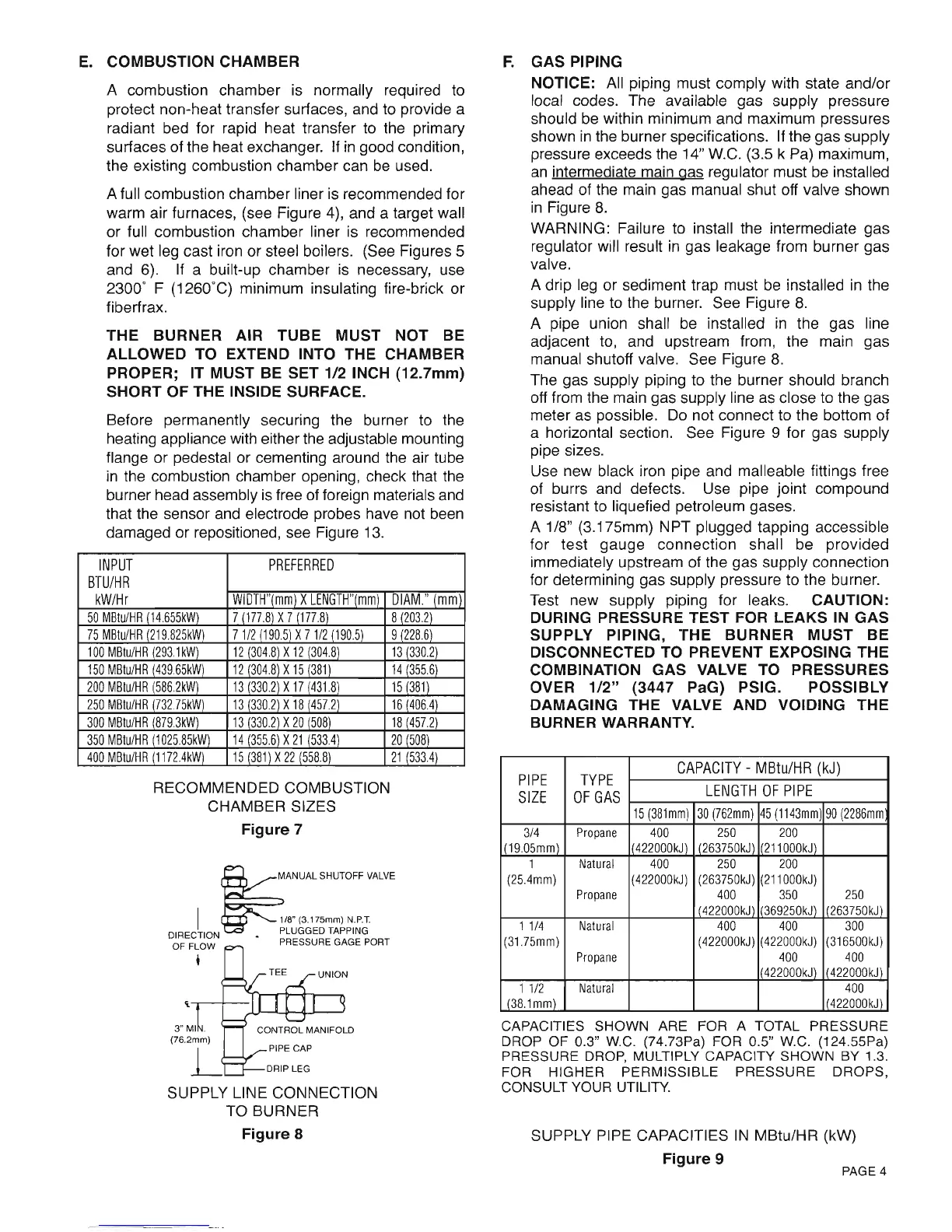

INPUT

PREFERRED

BTU/HR

kW/Hr

WIDTH"(mm)

X

LENGTH"(mm)

DIAM."

(mm

50

MBtu/HR

(14655kW)

7

(177.8)

X7

(177.8)

8

(203.2)

75

MBtu/HR

(219825kW)

71/2

(1905)

X

71/2

(190.5)

9

(2286)

100

MBtu/HR

293,lkW)

12

304,8

X

12

304.8)

13

330.2)

150

MBtu/HR

43965kW)

12

304.8

X

15

381)

14

3556)

200

MBtu/HR

586,2kW)

13

330.2

X17

431.8)

15

381)

250

MBtu/HR

73275kW)

13

330.2

X

18

457.2)

16

4064)

300

MBtu/HR

8793kW)

13

330.2

X

20

508)

18

457.2)

350

MBtu/HR

102585kW)

14

355.6

X

21

5334)

20

508)

400

MBtu/HR

11724kW)

15

381)

X

22

(558.8)

21

5334)

RECOMMENDED COMBUSTION

CHAMBER SIZES

Figure 7

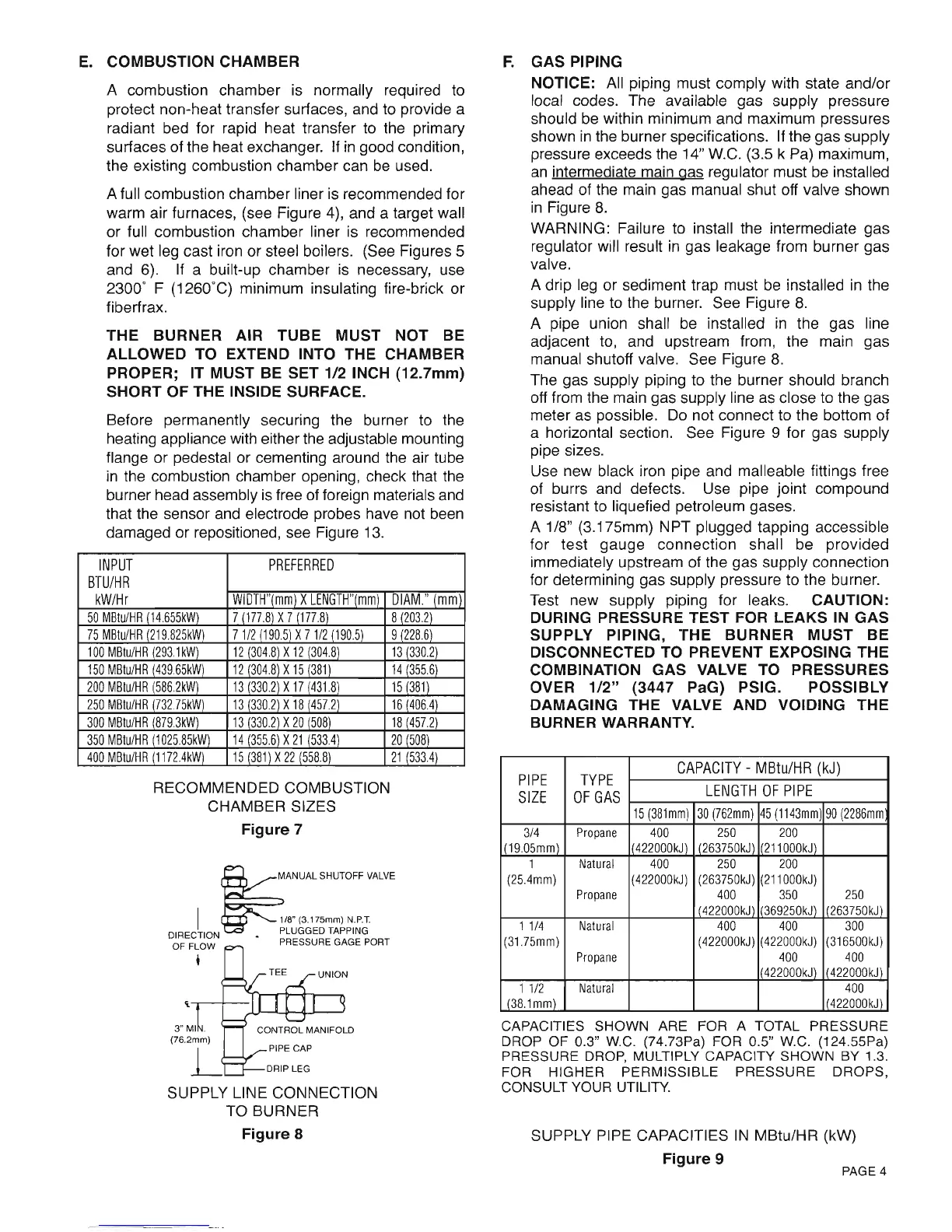

~

ANUALSHUTOFFVALVE

I 1/8" (3,175mm)

N.P.T.

DIRECTION • PLUGGED TAPPING

OF FLOW PRESSURE GAGE PORT

I

'i,--y--+-

PIPE CAP

DRIP LEG

SUPPLY LINE COI\II\IECTION

TO BURNER

Figure 8

F.

GAS PIPING

NOTICE:

All piping must comply with state

andlor

local codes. The available gas supply pressure

should be within minimum and maximum pressures

shown

in

the burner specifications. If the

gas

supply

pressure exceeds the 14" W.C. (3.5 k Pa) maximum,

an

intermediate main gas regulator must be installed

ahead of the main gas manual shut off valve shown

in

Figure

8.

WARNING: Failure to install the intermediate

gas

regulator will result

in

gas leakage from burner gas

valve.

A drip leg or sediment trap must be installed in the

supply line to the burner. See Figure

8.

A pipe union shall be installed

in

the gas line

adjacent to, and upstream from, the main gas

manual shutoff valve. See Figure

8.

The gas supply piping to the burner should branch

off from the main gas supply line as close to the gas

meter as possible. Do not connect to the bottom

of

a horizontal section. See Figure 9 for gas supply

pipe sizes.

Use new black iron pipe and malleable fittings free

of burrs and defects. Use pipe joint compound

resistant to liquefied petroleum gases.

A 1/8" (3.175mm) NPT plugged tapping accessible

for

test

gauge

connection

shall be

provided

immediately upstream of the gas supply connection

for determining gas supply pressure to the burner.

Test new supply piping for leaks.

CAUTION:

DURING PRESSURE TEST FOR LEAKS

IN

GAS

SUPPLY PIPING, THE BURNER

MUST

BE

DISCONNECTED TO PREVENT EXPOSING THE

COMBINATION GAS VALVE TO PRESSURES

OVER

1/2"

(3447

PaG) PSIG. POSSIBLY

DAMAGING THE VALVE AND VOIDING THE

BURNER WARRANTY.

PIPE

TYPE

CAPACITY

- MBtu/HR

(kJ)

SIZE

OF

GAS

LEI~GTH

OF

PIPE

15

(381mm)

30

(762mm)

45

(1143mm)

90

(2286mm

3/4

Propane

400

250 200

1(19.05mm)

422000kJ)

I

(263750kJ)

211000kJ)

1

Natural

400

250

200

(25.4mm)

(

422000kJ)

(263750kJ)

(211000kJ)

Propane

400

350

250

I

(422000kJ)

369250kJ)

'263750kJ)

1

1/4

Natural

400 400

300

(31.75mm)

(422000kJ)

(422000kJ)

(316500kJ)

Propane

400 400

422000kJ) 422000kJ)

1

1/2

Natural

400

(38.1mm)

'422000kJ)

CAPACITIES SHOWN ARE FOR A TOTAL

PRESSURE

DROP

OF

0.3" W.C. (74.73Pa) FOR 0.5" W.C. (124.55Pa)

PRESSURE DROP, MULTIPLY CAPACITY SHOWN BY 1.3.

FOR

HIGHER

PERMISSIBLE

PRESSURE

DROPS,

CONSULT YOUR UTILITY.

SUPPLY PIPE CAPACITIES

IN

MBtulHR (kW)

Figure 9

Loading...

Loading...