G. ELECTRICAL

The installation must

be

wired

and GROUNDED

in

accordance

with local

codes or

in their

absence,

with

the

National

Electric Code ANSI/NFPA No. 70-

1987

or

latest

edition.

For

the 120 VAC wiring

to

the burner,

use solid

copper conductor wire not lighter than #14 AWG. lf

a

fused

disconnect

is

used, it should be

fused

for a

minimum

of

15

amps.

CAUTION:

Each installation must include

suitable

limit controls. Existing oil burner

combination limit

and operating controls are normally

not

suitable

for

gas

burner use.

CAUTION:

The burner is

equipped

with it's own 24

VAC

transformer. Do

not

add any

24 VAC

power

consuming device in

the

24 VAC control

circuit of

the burner, as it could overload the transformer.

Set

the room thermostat

"heat

anticipator" for the

totaf current draw of the 24

VAC

burner operation

circuit.

(HSG200

0.55 amps,

HSG400

0.7 amps)

GAUTION:

Label

all

wires

orior

to disconnection

when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify

proper

operation after

servicing.

NOTE: lf

any of

the

original burner

wiring must

be

replaced, it must

be

replaced with #18

AWG 105 degrees

C

wire or equivalent.

Section 3- Operation and

Troubleshooting for

applicable burner wiring diagrams.

H. MAIN

BURNER

ORIFICE SIZING

AND INSTALLATION

The HSG200 and HSG400

power gas

conversion

burners are approved for use with natural

and

propane

gas

only.

The HSG200 and HSG400

burner

models

are

shipped

labeled

and orificed for natural

gas.

To

conveft to

propane gas

and/or increase BTU/HR

(kcal/Hr)

input on natural or

propane

gas,

an

orifice

kit is

supplied

with

each burner

with the

orifices

shown

in Figure

10.

When selecting a desired BTU/HR

(kcal/Hr)

input,

figure 140,000 BTU's

per

gallon

of

oil input. For

example:

furnace or

boiler

rating

of 0.75gph at

100

psig.

The

0.75 x

140,000

=

105,000

BTU's input

rate. lt may be

possible

to reduce the firing rate on

natural

or

propane gas

15%

lo

20o/",

as

most

older

appliances are oversized for the heating load.

(2.83875L

x 9356 kcal

=

26559.35 kcal)

To

remove

or

interchange main

orifice discs

refer

to

Figure 15

(Page

16).

1. Remove slotted orifice cap,

ltem #40, making

sure orifice

cap

gasket,

#39,

stays

attached to

orifice cap and

is not

damaged.

2. Remove orifice

spring,

ltem #38, to access

and

remove orifice disc. ltem #42.

3.

Install desired orifice from Figure 10, making

sure

it is

seated

flat in

the orifice

holder,

ltem

#37.

4. Replace orifice

spring and securely tighten

orifice cap against orifice cap

gasket

in orifice

holder.

NOTE: For

50 cycle

application

derate input

by

15%

HSG

SERIES

POWER

GAS

CONVERSION BURNERS

ORIFICE CHART

Figure

10

ORIFICE

SIZE & DRILL

MANIFOLD PRESSURE

2.0"

(498.2Pa)

3.0"

(747.3Pa)

4.0"

(996.4Pa)

HSG2OO NATURAL

GAS

#29 - .136

(3.4544mm)

50.000 BTU

(52750kJ)

64.000 BTU {67520kJ)

76.500 BTU

(80707.5kJ

#8 - .199

(5.0546mm)

i4,000

BTU

(78070kJ)

95.000 BTU

(100225kJ)

116.000 BTU

(122380kJ

J

-

.277

(7.0358mm)

112.000 BTU

(118160kJ)

138.000 BTU

(145590kJ)

164.000

BTU

(173020kJ

Q

-

.332

(8.4328mm)

160,000 BTU

(168800kJ)

206,000

BTU

(217330kJ)

HSG2OO L.P.

GAS

#30 - 128

(3.2512mm)

49.000 BTU

(5169skJ)

58.500 BTU

(61717.5kJ)

68.200 BTU

(71951kJ)

#27 -

j44

(3.6576mm)

66.000 BTU

(69630kJ)

78,000

BTU

(82290kJ)

92.000 BTU

{97060kJ)

#15

-.180

(4.572mm)

82.000 BTU

(86510kJ)

'1

12.500 BTU

(1

1 8687.5kJ)136.000 BTtl

(143480kJ)

D

-

.246

(6.2484mm)

131,000 BTU

(138205kJ)

1 87.500 BTU

(1

9781

2.5kJ)243,000 BTU

(256365kJ)

HSG4OO NATURAL

GAS

T

-

.358

(9.0932mm)

200.000 BTU

(211000kJ)

248.000 BTU

(261640kJ)

285000 BTU

(300675kJ)

15/32 -

.468

(11.8872mm)

265,000

BTU

(279575kJ)

343.000 BTU

{361865kJ)

400,000 BTU

(422000kJ)

HSG4OO L.P.

GAS

K - .281

(7.1374mm)

190.000

BTU

(200450kJ)

242.500 BTU

(255837.5kJ

)

295.000

BTU {311225kJ)

0-

.332

(8.4328mm)

242,500 BTU

(255837kJ)

332,500 BTU

(350787.5kJ)

400,000

BTU

(422000kJ)

PAGE

5

G.

ELECTRICAL

The installation must be wired and GROUNDED

in

accordance with local codes or

in

their absence,

with the National Electric Code ANSI/NFPA

No.

70-

1987 or latest edition.

For the 120

VAC

wiring

to

the burner, use solid

copper conductor wire not lighter than #14 AWG.

If

a fused disconnect is used, it should

be

fused for a

minimum of 15 amps.

CAUTION: Each installation must include suitable

limit controls. Existing oil burner combination limit

and operating controls are normally not suitable for

gas burner use.

CAUTION: The burner is equipped with it's own 24

VAC

transformer.

Do

not add any 24

VAC

power

consuming device

in

the 24

VAC

control circuit of

the burner, as

it

could overload the transformer.

Set the room thermostat "heat anticipator" for the

total current draw of the 24

VAC

burner operation

circuit. (HSG200 0.55 amps, HSG400 0.7 amps)

CAUTION: Label

all

wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

NOTE: If any of the original burner wiring must

be

replaced, it must

be

replaced with #18

AWG 105 degrees C wire or equivalent.

Section 3- Operation and Troubleshooting for

applicable burner wiring diagrams.

H.

MAIN BURNER ORIFICE SIZING

AND INSTALLATION

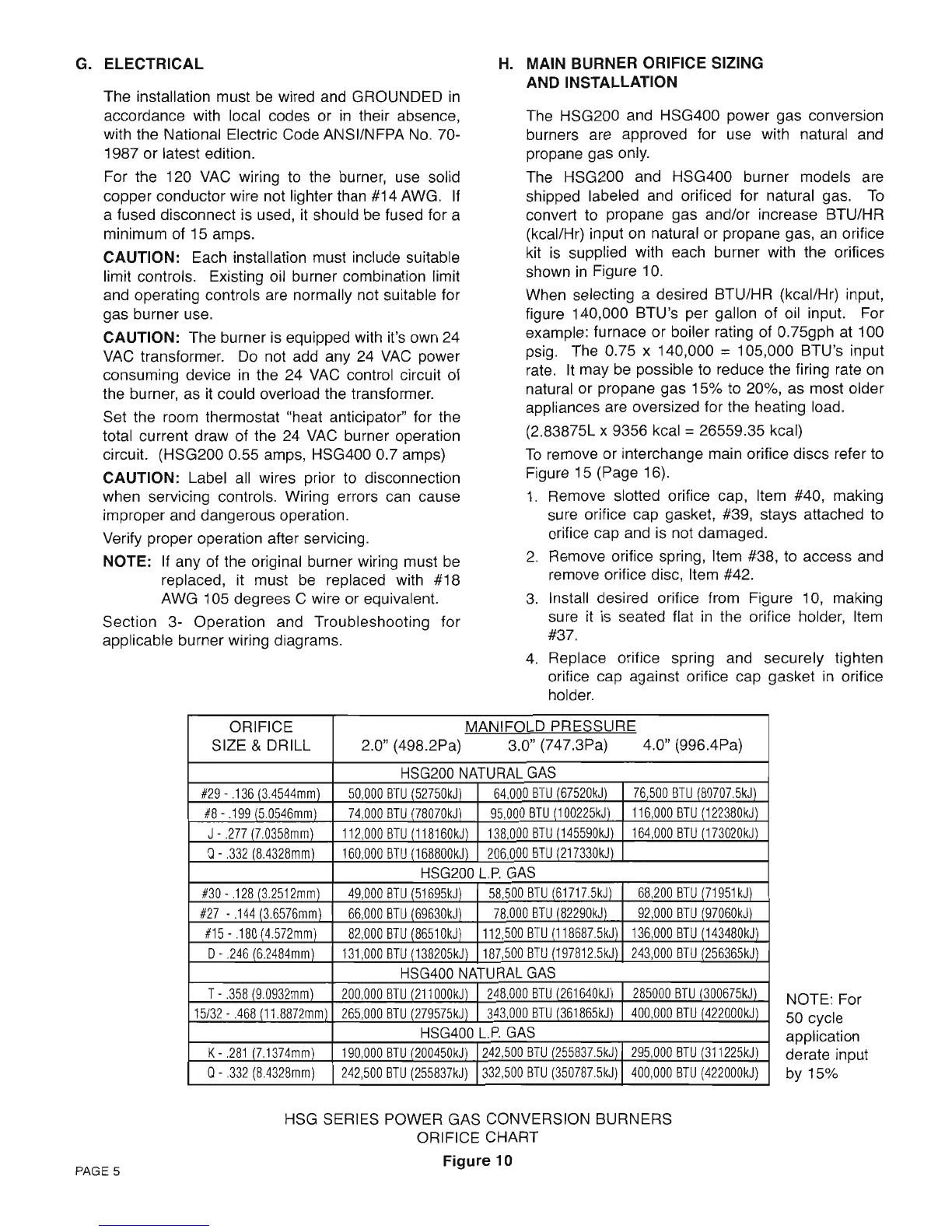

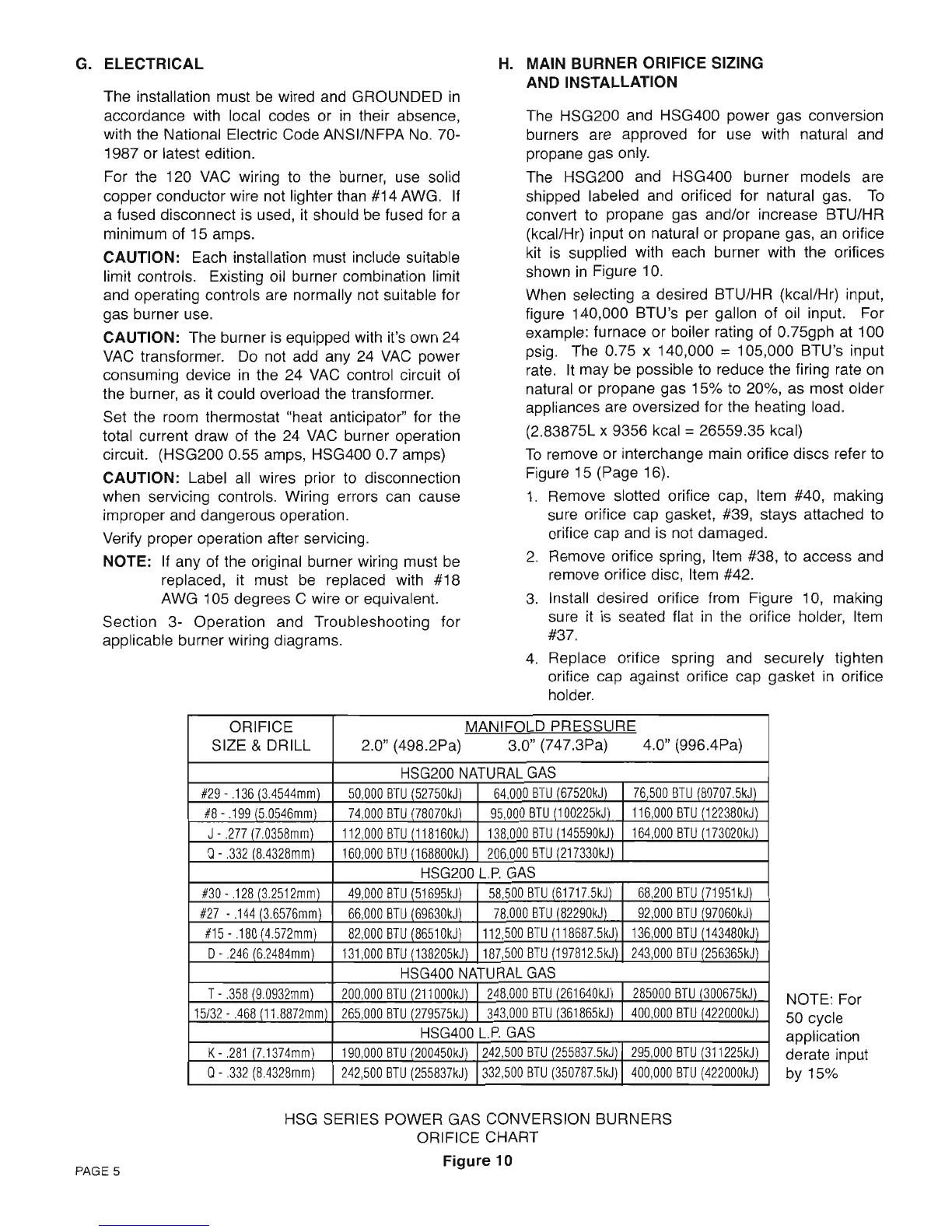

The HSG200 and HSG400 power gas conversion

burners are approved for use with natural and

propane gas only.

The HSG200 and HSG400 burner models are

shipped labeled and orificed for natural gas.

To

convert to propane gas and/or increase BTU/HR

(kcal/Hr) input

on

natural or propane gas,

an

orifice

kit

is

supplied with each burner with the orifices

shown

in

Figure 10.

When selecting a desired BTU/HR (kcal/Hr) input,

figure 140,000 BTU's per gallon of oil input. For

example: furnace or boiler rating of 0.75gph at 100

psig. The 0.75 x 140,000

==

105,000 BTU's input

rate.

It

may

be

possible to reduce the firing rate

on

natural or propane gas 15%

to

20%, as most older

appliances are oversized for the heating load.

(2.83875L x 9356 kcal

==

26559.35 kcal)

To

remove or interchange main orifice discs refer

to

Figure 15 (Page 16).

1.

Remove slotted orifice cap, Item #40, making

sure orifice cap gasket, #39, stays attached to

orifice cap and is not damaged.

2.

Remove orifice spring, Item #38,

to

access and

remove orifice disc, Item #42.

3.

Install desired orifice from Figure 10, making

sure

it

is

seated flat

in

the orifice holder, Item

#37.

4.

Replace orifice spring and securely tighten

orifice cap against orifice cap gasket

in

orifice

holder.

PAGE 5

ORIFICE

MANIFOLD PRESSURE

SIZE

& DRILL

2.0" (498.2Pa) 3.0" (747.3Pa)

4.0" (996.4Pa)

HSG200

NATURAL

GAS

#29

-

.136

(3.4544mm)

50,000

BTU

152750kJl

64,000

BTU

167520kJ)

76

500

BTU

180707.5kJ)

#8

-

.199

(5.0546mml

74,000

BTU

178070kJ)

95,000

BTU

(1

00225kJ)

116,000

BTU

(122380kJ)

J-

.277

(7.0358mm)

112,000

BTU

(118160kJ)

138,000

BTU

1145590kJ)

164,000

BTU

1173020kJ)

Q -

.332

(8.4328mm)

160,000

BTU

1168800kJ)

206,000

BTU

(217330kJ)

HSG200

L.P.

GAS

#30

-

.128

13.2512mm)

49,000

BTU

151695kJ)

58,500

BTU

161717.5kJ)

68,200

BTU

171951

kJ)

#27

-

.144

(3.6576mm)

66,000

BTU

169630kJ)

78,000

BTU

182290kJ)

92,000

BTU

197060kJ)

#15

-

.180

14572mm)

82,000

BTU

186510kJ)

112,500

BTU

1118687.5kJ)

136,000

BTU

1143480kJ)

D·

.246

(6.2484mm)

131,000

BTU

1138205kJ)

187,500

BTU

(197812.5kJ)

243,000

BTU

1256365kJ)

HSG400

NATURAL

GAS

T-

.358

(9.0932mm)

200,000

BTU

(211

OOOkJl

248,000

BTU

1261640kJ)

285000

BTU

1300675kJ)

15/32

-

.468

(11.8872mm)

265,000

BTU

(279575kJ)

343,000

BTU

(361865kJ)

400,000

BTU

(422000kJl

HSG400

L.P.

GAS

K-

.281

(7.1374mm)

190,000

BTU

(200450kJ)

242,500

BTU

(255837.5kJ)

295,000

BTU

1311225kJl

Q -

.332

(8.4328mm)

242,500

BTU

(255837kJ)

332,500

BTU

(350787.5kJ)

400,000

BTU

(422000kJ)

HSG SERIES POWER GAS CONVERSION BURNERS

ORIFICE CHART

Figure

10

NOTE: For

50 cycle

application

derate input

by 15%

Loading...

Loading...