D. The

flue

gas

temperature

should be between

325"F

(162.78"C)

and 550"F

(287.78"C)tor

domestic

gas

conversion burners.

Higher flue

gas

temperatures

indicate

overfiring or

excessive draft through the appliance.

Lower

flue

gas

temperatures may cause excessive

condensation and

indicate

underfiring. Consult

your

local utility or the appliance manufacturer

for

acceptable

flue

gas

temperatures.

CAUTION:

lF THE BURNER BTU/HR

(kWHr)

INPUT IS

CHANGED.

REPEAT STEP 13

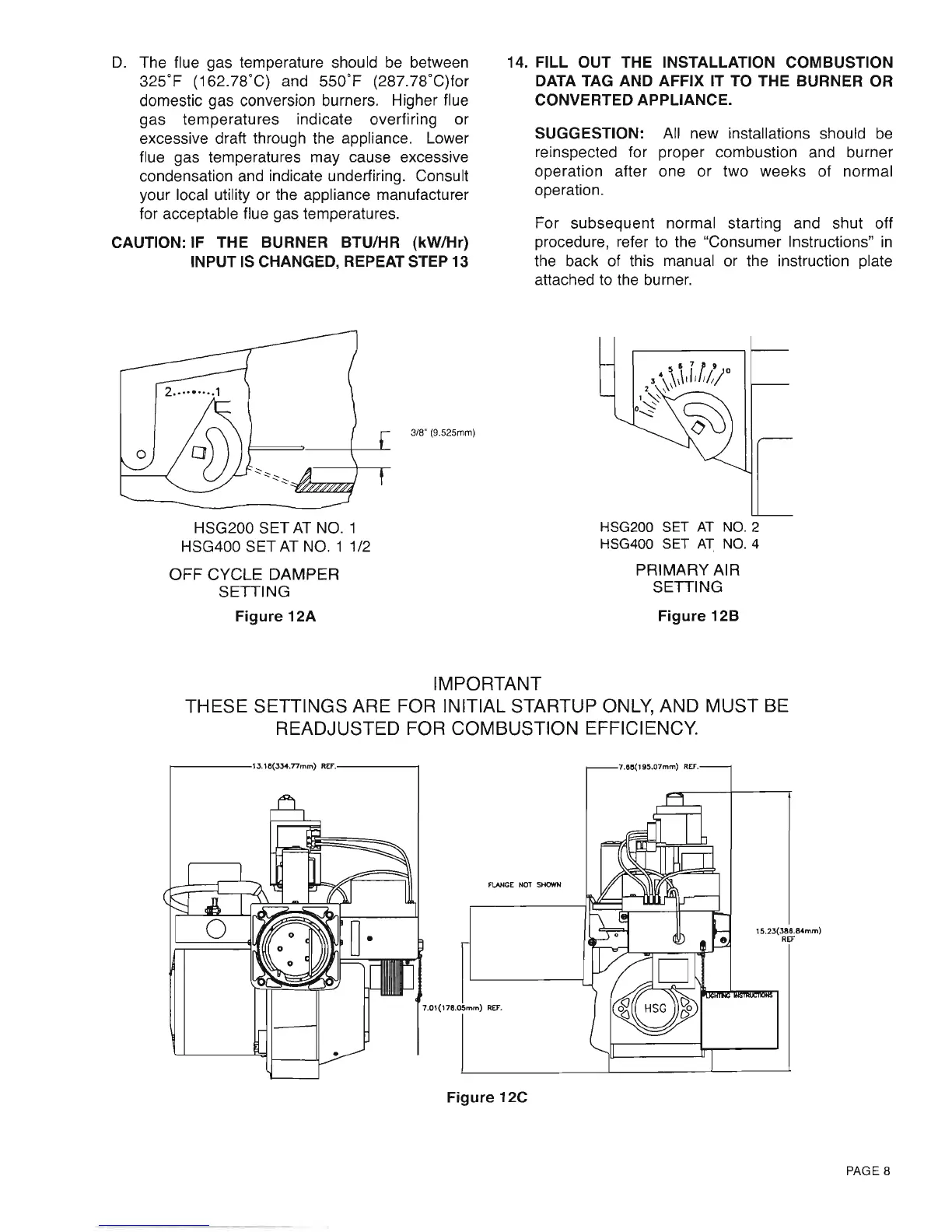

3/8"

(9.525mm)

HSG2OO SETAT

NO. 1

HSG4OO

SETAT

NO. 1 1/2

OFF CYCLE

DAMPER

SETTING

Figure 12A

14. FILL

OUT

THE INSTALLATION

COMBUSTION

DATA

TAG AND

AFFIX IT TO THE BURNER

OR

CONVERTED

APPLIANCE.

SUGGESTION: All

new

installations should

be

reinspected for

proper

combustion and burner

operation after one or two weeks of normal

operation.

For

subsequent normal starting and shut off

procedure,

refer to the

"Consumer

lnstructions" in

the back of this manual or the instruction

plate

attached

to the burner.

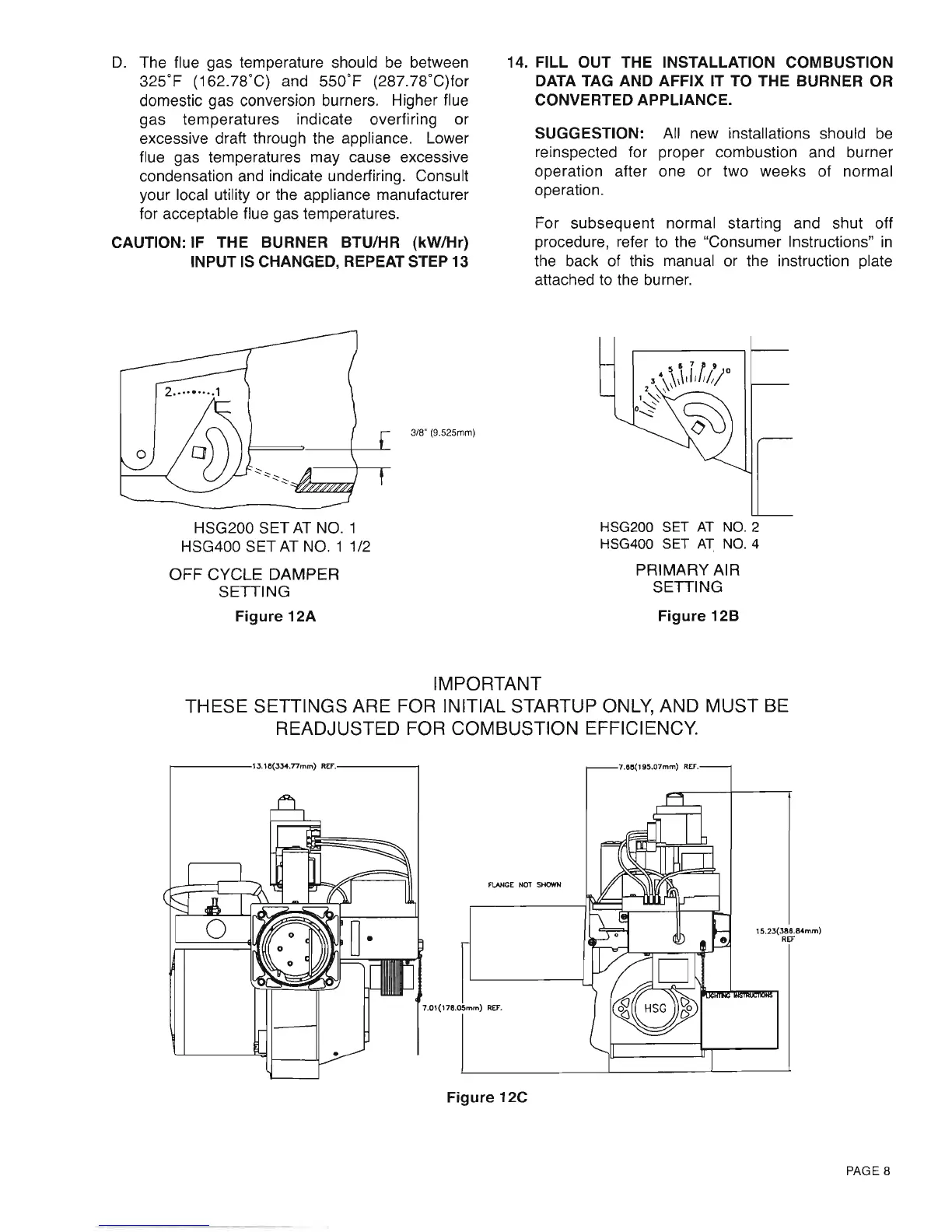

HSG2OO SET

AT NO.2

HSG4OO SET

AT NO.4

PRIMARY AIR

SETTING

Figure

128

IMPORTANT

THESE

SETTINGS

ARE

FOR

INITIAL

STARTUP ONLY

AND MUST BE

READJUSTED FOR

COMBUSTION

EFFICIENCY.

,ssK

Figure 12C

PAGE

8

D.

The flue gas temperature should

be

between

325'F

(162.78'C) and

550'F

(287.78'C)for

domestic gas conversion burners. Higher flue

gas temperatures indicate overfiring or

excessive draft through the appliance. Lower

flue gas temperatures may cause excessive

condensation and indicate underfiring. Consult

your local utility or the appliance manufacturer

for acceptable flue gas temperatures.

CAUTION: IF THE BURNER BTU/HR (kWlHr)

INPUT

IS

CHANGED, REPEAT STEP 13

14. FILL OUT THE INSTALLATION COMBUSTION

DATA TAG AND AFFIX IT

TO

THE BURNER

OR

CONVERTED APPLIANCE.

SUGGESTION: All new installations should

be

reinspected for proper combustion and burner

operation after one or two weeks of normal

operation.

For subsequent normal starting and shut off

procedure, refer to the "Consumer Instructions"

in

the back of this manual or the instruction plate

attached

to

the burner.

3/8" (9.525mm)

HSG200 SET

AT

NO.1

HSG400 SET

AT

NO.1 1/2

OFF

CYCLE DAMPER

SETTING

Figure

12A

HSG200 SET

AT

NO.2

HSG400 SET

AT

NO.4

PRIMARY AIR

SETTING

Figure

12B

IMPORTANT

THESE SETTINGS ARE FOR INITIAL STARTUP

ONLY,

AND MUST BE

READJUSTED FOR COMBUSTION EFFICIENCY.

r----1J.18(JJ4.77mm)

REF

..

----j

FlANGE

NOT

SHOWN

7.01(178.05mm)

REF.

Figure

12C

7.88('95.07mm)

REF.

15.2J(J86.84mm)

REF

PAGE 8

Loading...

Loading...