4

www.waynepumps.com

Operating Instructions and Parts Manual

OPERATION

Never run the pump dry. Running pump without

water may cause seal damage. Fill the pump

with water before starting.

PRIMING THE PUMP

After pump installation is complete, the pump must be primed. Remove

the pipe plug in the discharge piping and ll the pump and suction pipe

with clean water. Turn power to pump on. If the pump does not pump

water in 10 minutes, turn o the pump and rell with clean water.

If the pump does not operate after repeated attempts, check the

following:

1. Vertical distance of pump to water level must not be over 25 feet.

2. Suction piping must be air tight.

3. Be sure valve(s) are open if used in discharge or suction piping.

Never run the pump with a closed or clogged

discharge. The water inside the pump could boil

and damage the pump.

MAINTENANCE

Maintain adequate ventilation for the pump motor. The motor bearings are

permanently lubricated at the factory. Additional lubrication is not required.

DRAINING FOR WINTER

Always protect pump and piping against freezing temperatures. If there is

any danger of freezing, drain the system. To drain the system:

1. Remove the pipe plug from the discharge tee.

2. Remove the 1/4” plug from the lower front face of the pump.

3. Drain all piping below the frost line.

LAWN SPRINKLER REBUILD KIT

• Disconnect all power from the pump

• Drain the pump and disconnect any plumbing.

• Remove the four bolts holding the volute to the seal plate.

• Remove the volute from the seal plate, you may need to use a

screwdriver to help separate the parts.

• Remove the square cut gasket from the seal plate and discard.

• Remove the three screws from the diuser and the diuser from

the seal plate. The intake on the diuser has an O-Ring seal and is

covered with a lubricant, remove the O-Ring and discard.

• Remove the black plastic cap from the back of the motor, exposing

the motor shaft end. (On the WLS200 you will have to remove the

plastic cover from the end of the motor.

• Using a large at blade screw driver to hold the motor shaft while

unscrewing the impeller.

• Remove the bellows portion of the shaft seal, making sure the metal

sleeve comes o as well, all you should see on the back of the

impeller is the brass colored threaded insert.

• Remove the ceramic seal and rubber boot from the seal pate, it

is easier to remove the seal by unbolting the seal plate from the

motor ange. If you remove the seal plate from the motor ange

make sure you torque the four bolts to 140 ±40 inch pounds when

reassembling it.

• Wipe down all the parts to remove any debris or loose rust.

• Reassemble the pump with new parts in reverse order.

• Push the ceramic seat of the shaft seal into the seal plate using the

cardboard ring provided to keep the ceramic face clean. You can

use a little water or dish soap to lubricate the seal pocket to make

assembly easier.

• Push the bellows side of the shaft seal over the impeller hub, you

can use a little water or dish soap to lubricate the impeller hub to

make assembly easier.

• Holding the motor shaft with a at blade screw driver, thread the

impeller onto the motor shaft, hand tighten. Lubricate the nose of

the impeller with Dow Corning III valve lubricant and sealant or other

potable water safe lubricant.

• Replace the plastic cap (or plastic cover on the WLS200) over the

motor shaft end.

• Put a new O-Ring on the diuser and lubricate the intake/O-Ring

area of the diuser with the same lubricant used on the impeller.

• Replace the diuser, rotating the diuser until the screw holes line up

with the ones in the seal plate. The diuser only goes on one way.

Torque the screws to 27±7 inch pounds.

• Slide the square cut gasket over the ange on the seal plate, make

sure not to let the gasket twist.

• Reassemble the volute to the pump being careful not to damage

the O-Ring on the diuser. Torque the four bolts to 240 ±40 inch

pounds.

• Reattach plumbing connection, reconnect the power and prime the

pump (See section on priming the pump). After reassembling the

pump, check for leaks. If a leak is detected, repair before using the

pump.

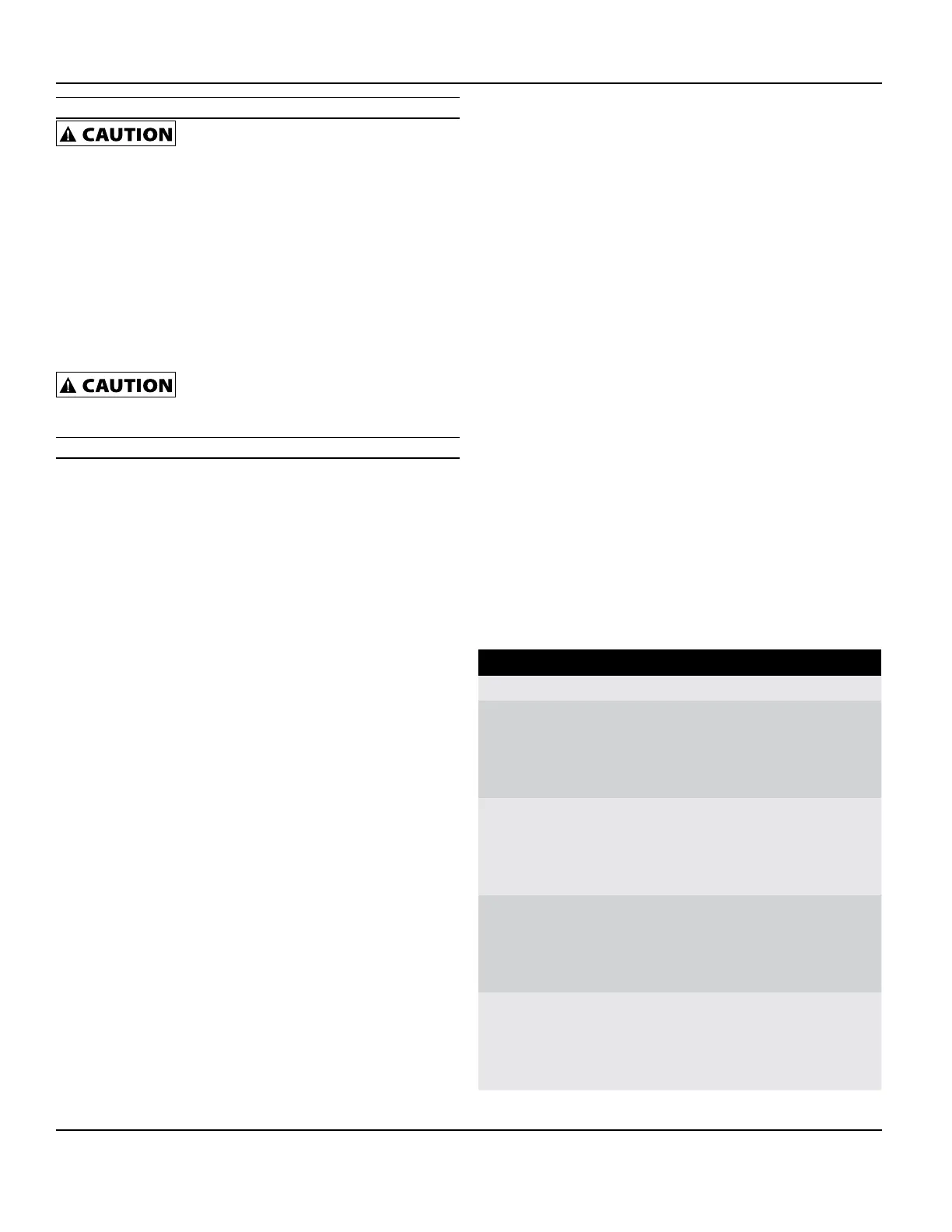

PERFORMANCE

Model PSI 5 ft. 10 ft. 15 ft. 20 ft. 25 ft.

WLS200

15 - - 5300 5150 4850

20 5300 5100 4850 4550 4300

25 4800 4500 4250 4000 3750

30

4200

3950 3750 3450 3100

WLS150

15 4350 4200 3950 3700 3500

20 3950 3700 3450 3250 3050

25 3400 3200 3000 2800 2550

30

2950

2750 2500 2150 1700

WLS100

15 3650 3450 3250 3050 2850

20 3200 3000 2850 2650 2500

25 2800 2650 2450 2300 2050

30

2450

2200 1950 1600 1150

WLS75

15 3100 2900 2750 2600 2450

20 2700 2550 2400 2200 2050

25 2350 2200 2000 1750 1450

30

1950

1700 1400 1000 500

Loading...

Loading...