18

Maintenance overview

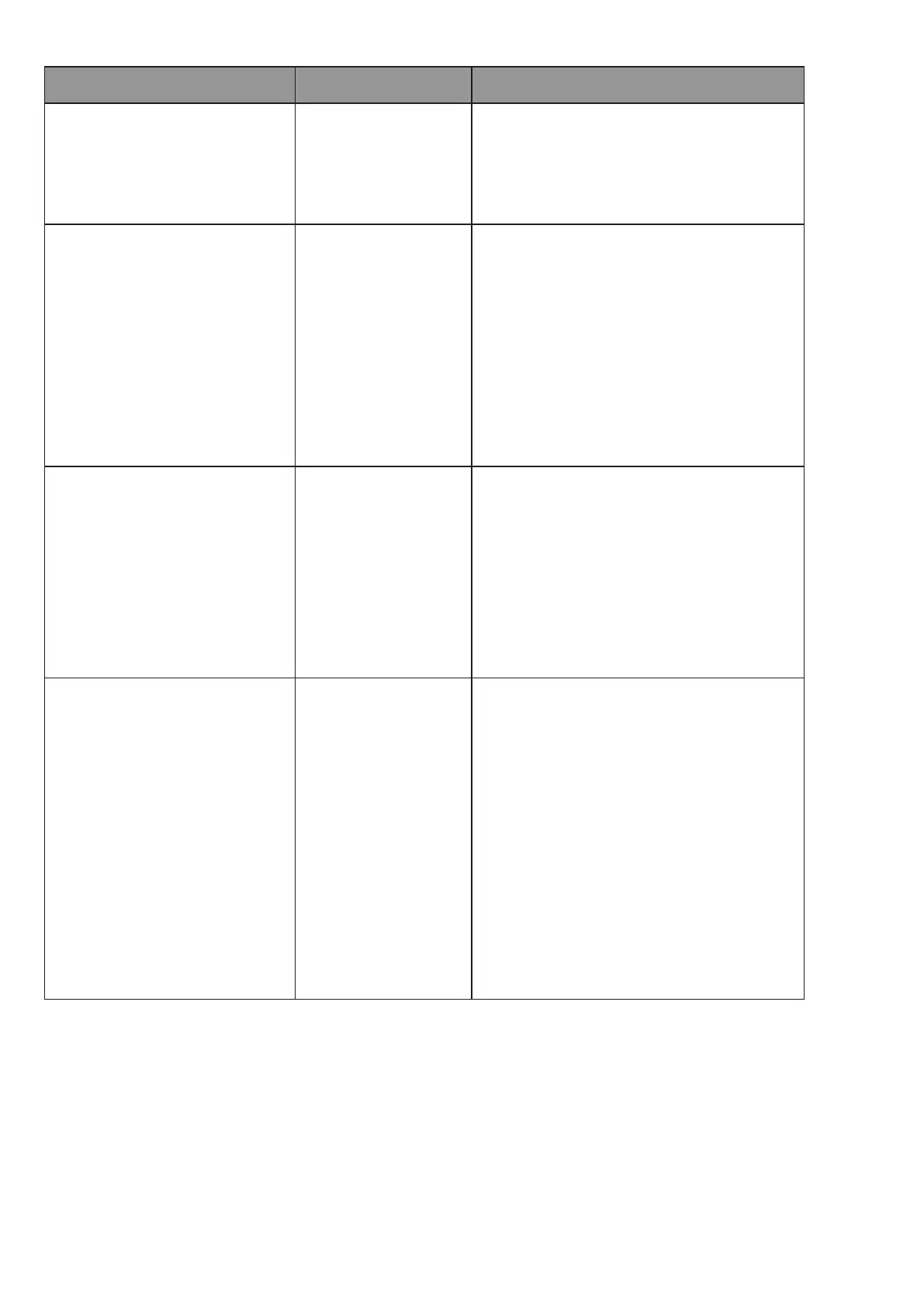

Maintenance interval Maintenance point Maintenance activity

After the rst 50 operating

hours

Hydraulic system - Change hydraulic uid lter

Engine - Change engine oil

Every 8 operating hours/

daily

Air lter -

Clean air lter insert, check for

damage, replace if necessary

Hydraulic system

- Check threaded unions, hoses for

leaks, tighten threaded unions or

change hoses as needed

- Only perform work if the hydraulic

system is de-pressurized!!

Engine - Check the engine oil level

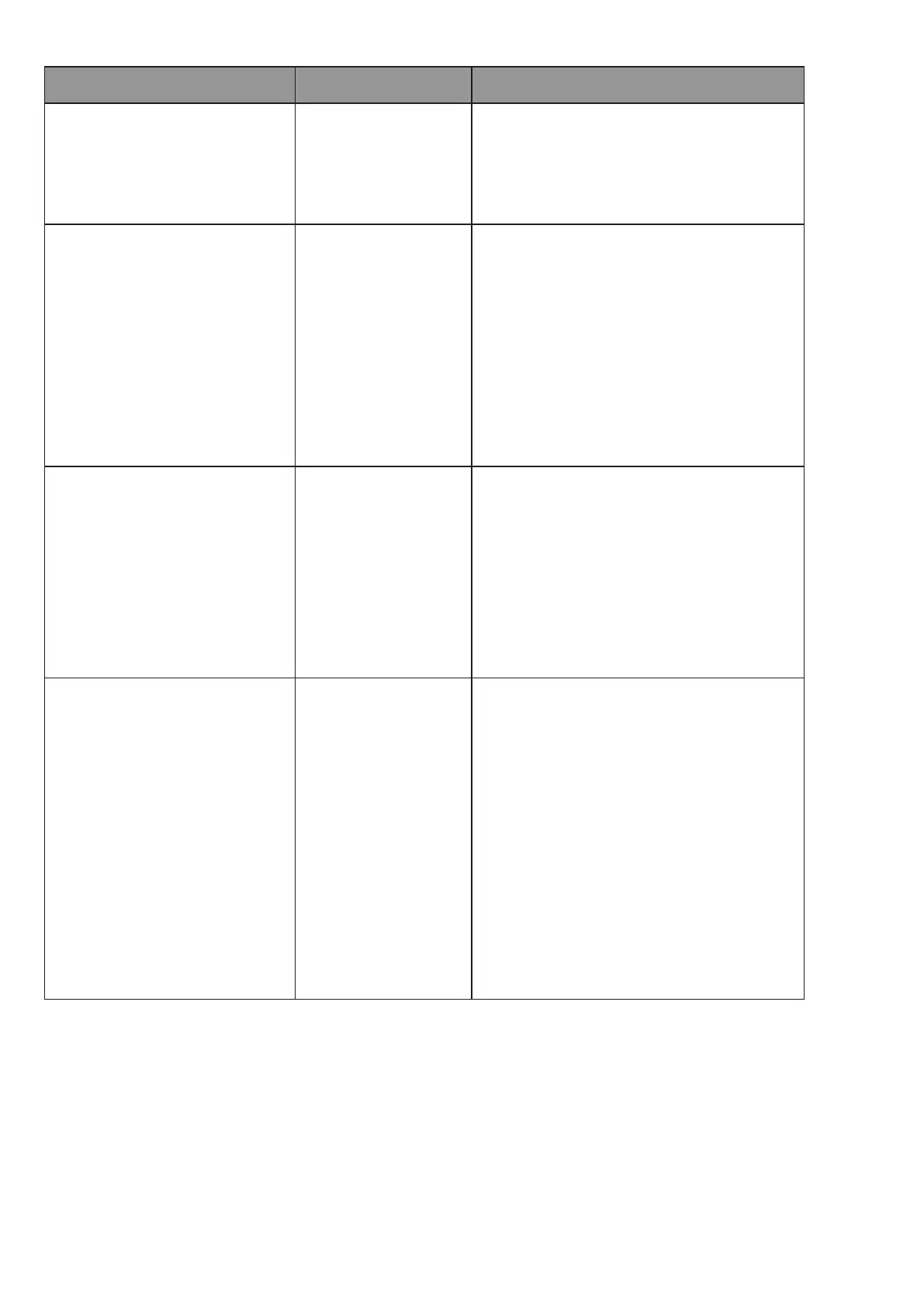

Every 150 operating hours/

every 6 months

Vibration shaft - Check V-belt for damage

Engine

- Change oil lter and engine oil

- Change the fuel lter

Drive chains - Lubricate, retighten if necessary

Scraper - Visually inspect or readjust

Every 300 operating hours/

every 6 months

Complete roller -

Check all modules for visible

damage and wear

- Remove fouling, old grease and rust

Hydraulic system

- Change hydraulic uid lter

- Change hydraulic uid

Water tank +

sprinkling system

- Clean, remove lime scale

Drive -

Check drive chains and drive pinion

for wear; retighten as needed

Loading...

Loading...