Manual no. WDT90100 Page 23

CoolTig - 220

automatically sense and identify the devices when connected. All remote controls

work at TIG mode only.

The maximum current remote control can adjust is limited to the current setting at

machine. If you want to use panel to set the welding current while connecting to a

remote current control torch, turn the current potentiometer in torch to max position,

then you can adjust welding current by panel control.

5-5. Short circuit protection while welding

TIG: After the welding arc has established, if the tungsten electrode touches

the work the current will automatically drop to 0A to prolong the life of

tungsten and reduce the contamination to the work piece.

STICK: If the electrode touches the work for more than two seconds the

welding current will drop to 0A.

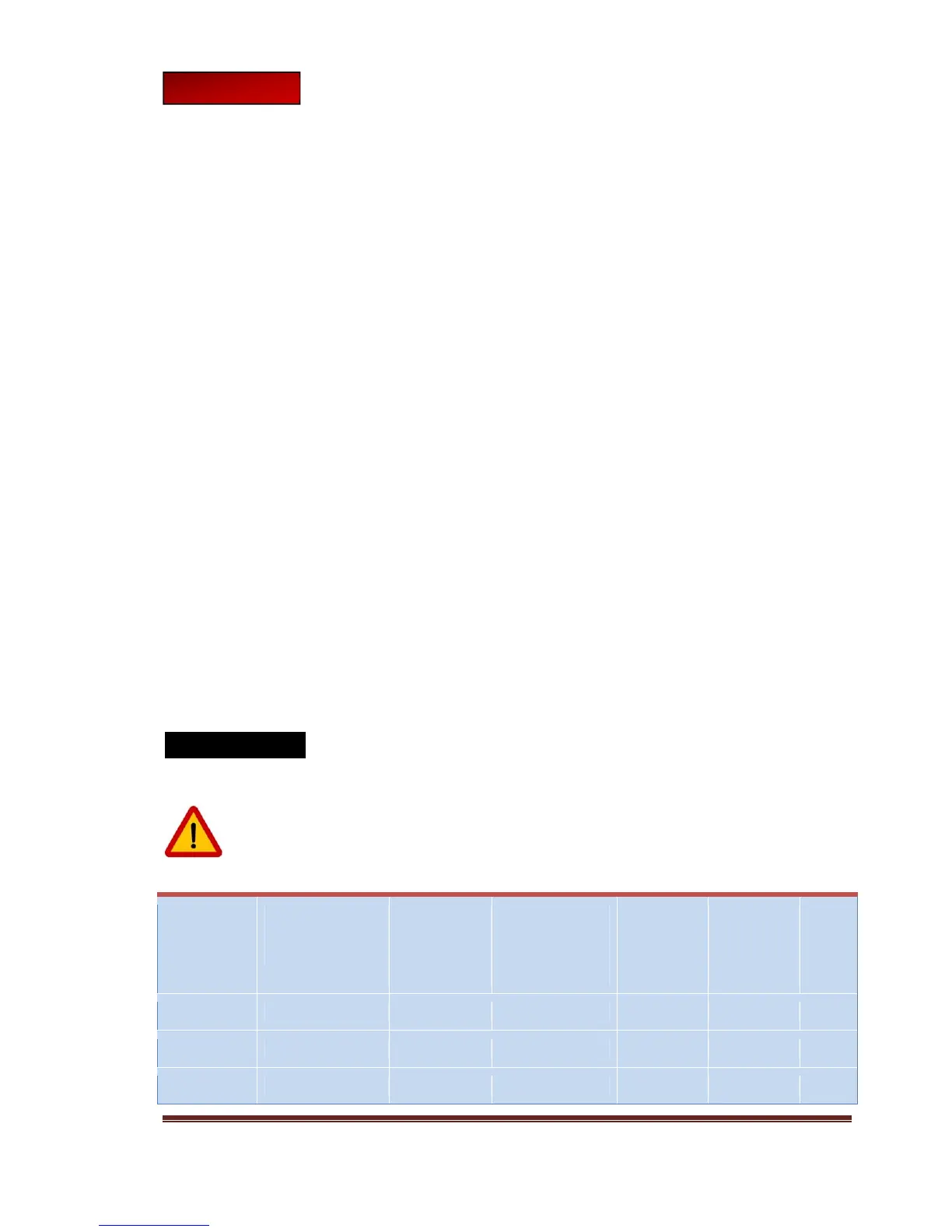

5-6. Welding Parameter selection chart

The setting listed below is just for initial commission of the machine. The parameter

can be refined during welding.

5-6.1.TIG welding parameter

CAUTION!

GRINDING THE TUNGSTEN ELECTRODE PRODUCES DUST AND FLYING

SPARKS WHICH CAN CAUSE INJURY AND START FIRES.USE LOCAL

EXHAUST AT THE GRINDER OR WEAR AN APPROVED RESPIRATOR

Plate

thickness

(mm)

Tungsten

electrode

diameter(mm)

Taper of

tungsten

electrode

(°)

Tungsten

electrode

end diameter

(mm)

Welding

current

(A)

Max

argon

flow rate

(L/min)

Weld

layer

0.2 1.0~1.6 10 0.1 10-15 2 1

0.4 1.0~1.6 20 0.12 15-20 2.5 1

0.6 1.0~1.6 20 0.25 15-30 2.5 1

Loading...

Loading...