ASSEMBLY & ADJUSTMENTS

14

ADJUST THE SPEED

Your variable speed lathe has three speed ranges: Low

250-720 RPM, Medium 600-1700 RPM, and High 1200-

3550 RPM. Always start at slower speeds for rough cuts

and larger workpieces. Use faster speeds for refined cuts

and detailed work.

Set the suitable speed range for your operation by adjust-

ing the belt position. Change the speed within a speed

range using the speed adjustment knob. The speed will be

displayed on the digital RPM readout (Fig. 17 - 1) on the

front panel.

1. Turn off and disconnect the lathe.

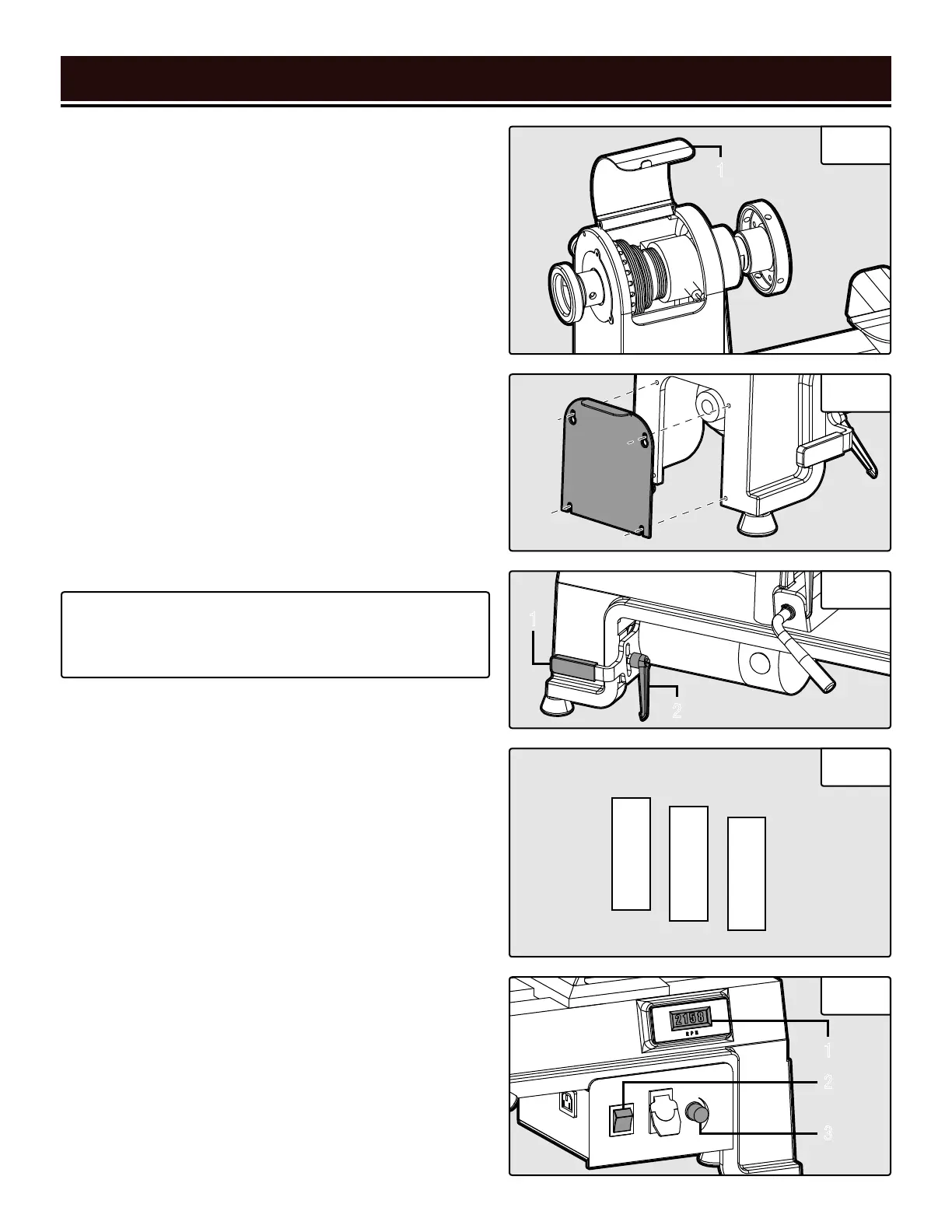

2. Open the belt drive access panel (Fig. 13 - 1).

3. Loosen (but do not remove) the four screws holding the

lower belt drive plate (Fig. 14) onto the left side of the head-

stock. Lift and remove the lower belt drive plate.

4. Loosen the motor tensioning locking handle (Fig. 15 - 2).

Fig. 13

Fig. 14

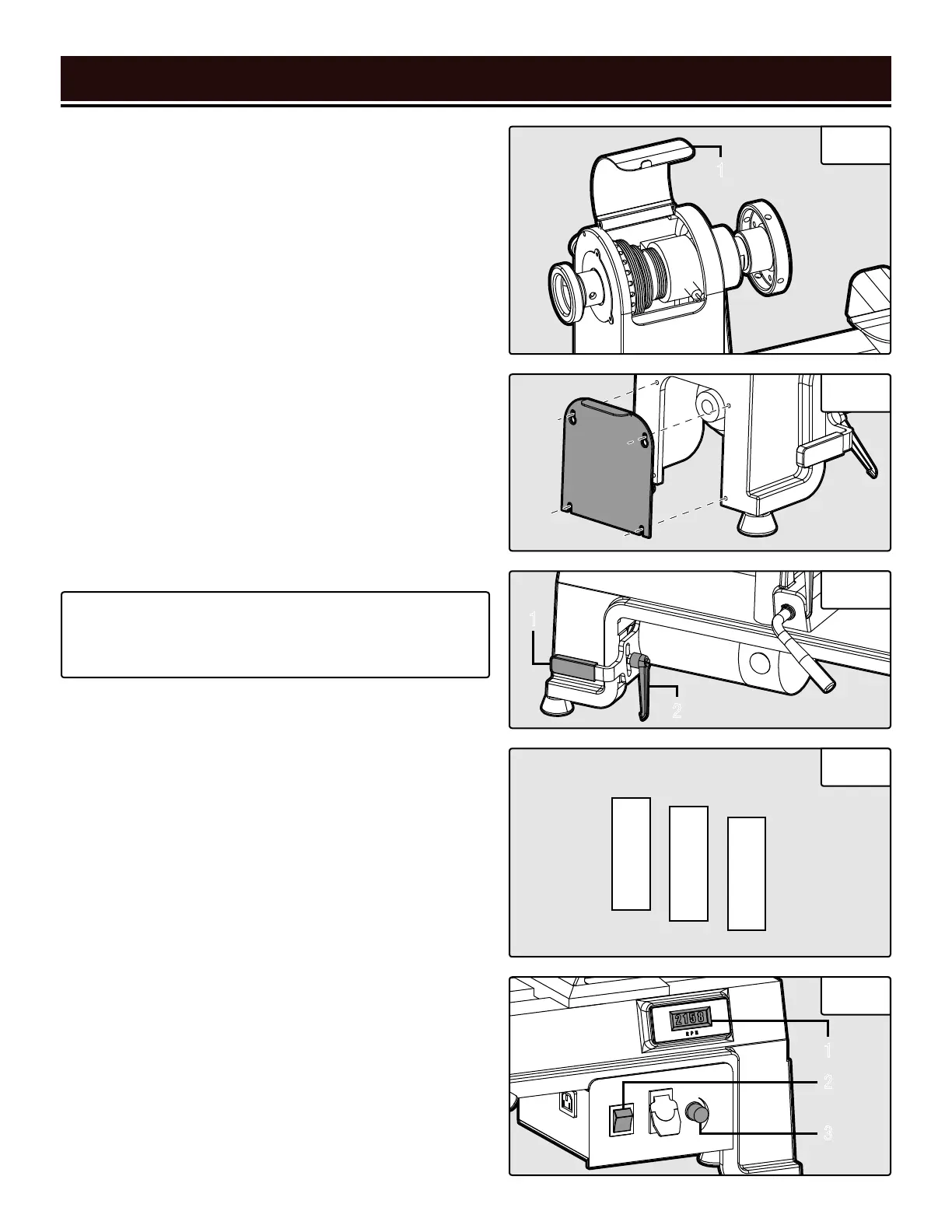

Belt Position Speed Chart (RPM)

Low

250

600

1200

720

1700

3550

Med

High

Fig. 16

1

Fig. 15

2

1

1

2

3

Fig. 17

NOTE: The locking handle is spring-loaded. To re-posi-

tion the handle, pull it outwards, place it in the desired

position, and let go.

5. Pull upwards on the tensioning handle (Fig. 15 - 1) to

relieve tension on the belt. It may help to wedge a piece of

wood or other support under the tensioning handle to keep

it in place while you adjust the belt position.

6. Adjust the belt’s position on both the upper and lower

drive pulleys to the desired speed range setting according

to Fig. 16. Make sure the belt is vertically aligned on the

upper and lower pulleys.

7. Lower the tensioning handle back to its original position,

allowing the weight of the motor to place the belt under

tension. Tighten the locking handle.

8. Replace the lower belt drive plate and tighten the screws.

Lower the upper belt drive access panel.

9. Use the speed adjustment knob (Fig. 17 - 3) on the front

panel to set the speed within your selected speed range.

Use the direction switch (Fig. 17 - 2) to set the rotational

direction. Do not change the direction when the tool is ON.

Loading...

Loading...