ASSEMBLY AND ADJUSTMENTS

12

WARNING: To avoid injury, make sure the chuck key is removed from

the chuck before starting any drilling operation.

INSTALLING A DRILL BIT

1. Place the chuck key into the side keyhole of the chuck, meshing the key

with the gear teeth.

2. Turn the chuck key counterclockwise to open the chuck jaws.

3. Insert a drill bit into the chuck far enough to obtain the maximum grip of

the chuck jaws.

4. Center the drill bit in the chuck jaws before the final tightening of the

chuck.

5. Tighten the chuck jaws using the chuck key to ensure that the drill bit will

not slip while drilling.

6. Remove the chuck key.

SQUARING THE TABLE TO THE DRILL BIT

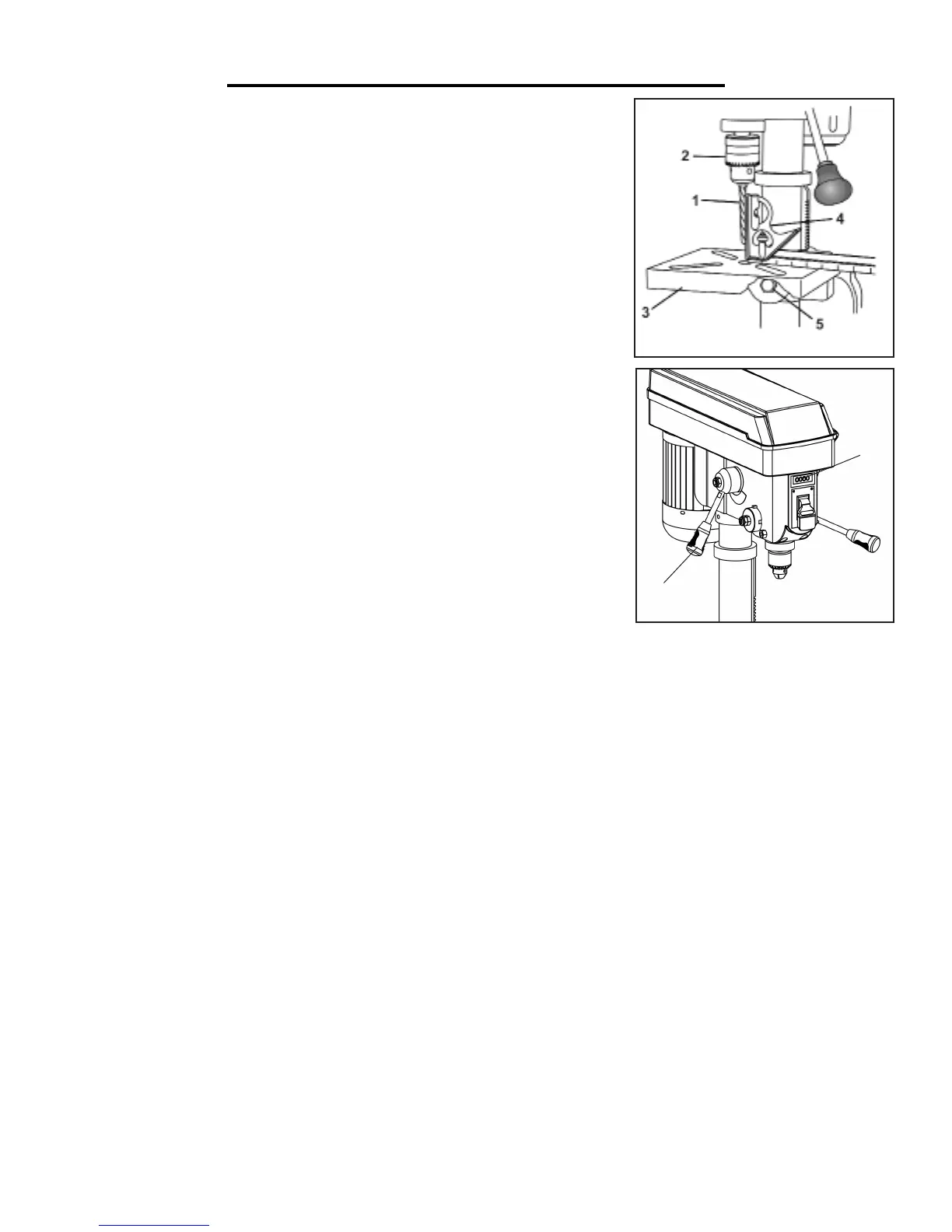

Fig. Q

Fig. R

2

1

1. Insert a 3-inch-long drill bit (Fig. Q - 1) into the chuck (Fig. Q - 2) and tighten.

2. Raise and lock the table (Fig. Q - 3) about 1” from the end of the drill bit.

3. Place a combination square (Fig. Q - 4) on the table as shown. The drill bit should be parallel to the straight

edge of the square.

4. If an adjustment is needed, loosen the bevel lock (Fig. Q - 5) with a wrench. Square the table to the bit by tilting

the table. Tighten the bevel lock bolt (Fig. Q - 5) when square.

VARIABLE SPEED ADJUSTMENT

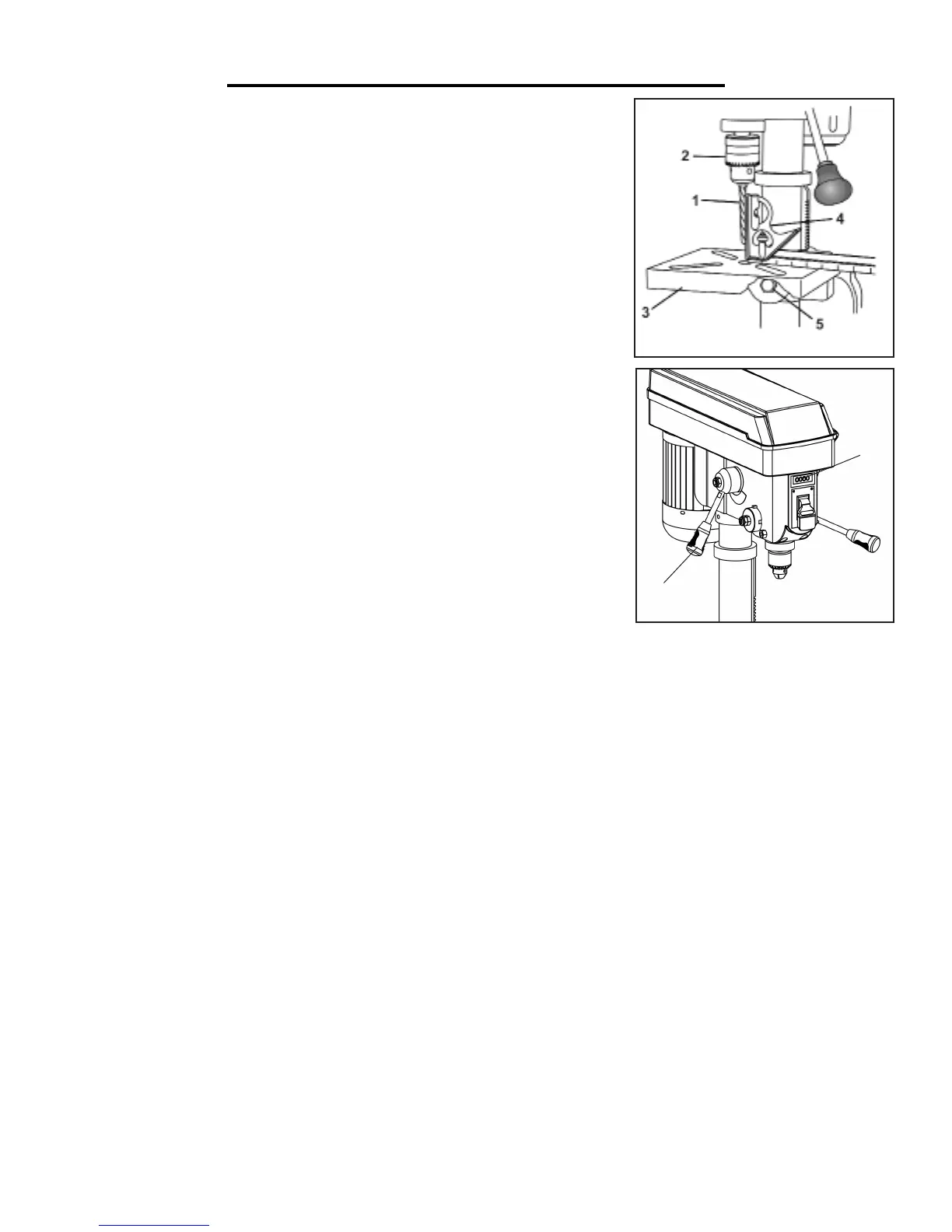

This is a mechanical variable speed drill press. To increase or decrease the speed, raise or lower the speed adjust-

ing handle (Fig. R - 1) while the drill press is running. When drilling, check the speed on the digital speed display

on the front of the drill press (Fig. R - 2).

NOTE: Do not attempt to change the drill press speed while the drill press is off. This can damage the drill press

and void the warranty.

Loading...

Loading...