12

ASSEMBLY

Unpacking

• Remove all packaging materials.

• Remove remaining packing and package inserts (if included).

• Check that the package contents are complete.

• Check the appliance, the power cord, the power plug and all accessories for

transportation damage.

• Keep the packing materials as long as possible until the end of the warranty

period.

WARNING

Packaging materials are not toys! Children must not play with plastic bags!

Danger of suffocation!

INSTALLATION OF RUBBER

FEET (Fig. 1)

• Insert the rubber feet into the

4 holes in the base (fig. 1).

INSTALLATION OF THE

DIAMOND DISC AND METAL

BRACKET (Fig. 2-12)

• Unplug the tile saw from the mains

supply.

• Remove the cover (45º vertical

fence) of the water tank (fig. 2).

• Remove the fixing screw & washer

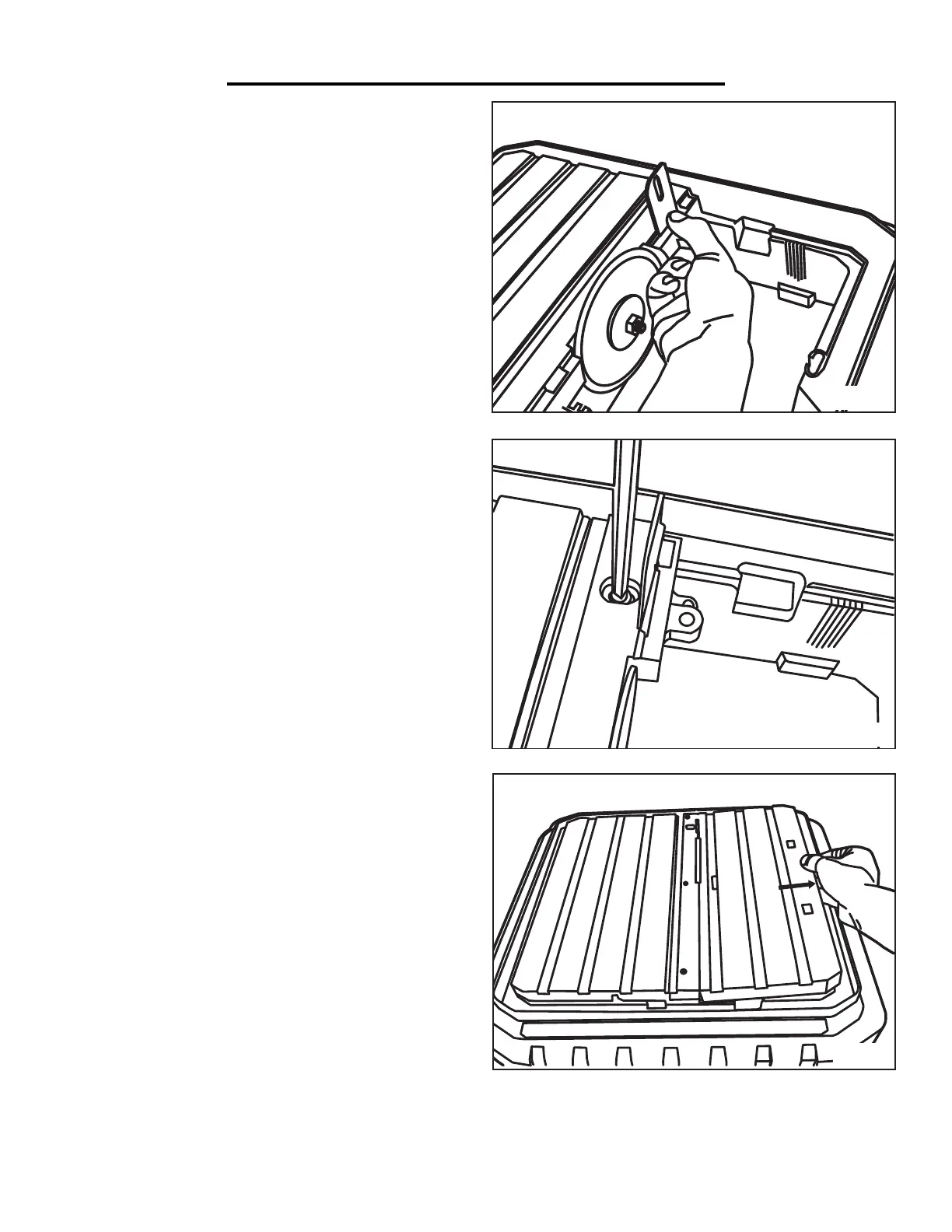

of the blade guard (fig. 3).

• Swing the blade guard then lift it

out of the notch (fig. 4-5).

• Remove the nut and outer flange

from the spindle (fig. 6).

• Fit the diamond disc (fig. 7). Please

pay attention to the rotation

direction on the diamond disc. The

direction arrows on the disc must

be in the same direction as that

marked on housing.

• Ensure the diamond disc is fully

located and centred.

fig.7

fig.1 fig.2

fig.3 fig.4

fig.5 fig.6

fig.8

ASSEMBLY & ADJUSTMENTS

13

ASSEMBLY

• Replace the outer flange and nut and

tighten securely with the two spanners

provided (fig. 8). Check that both

blade flanges are in contact with the

blade.

• Unscrew the screw & washer from

the metal bracket (fig. 9).

• Put the metal bracket under the

plastic housing then slide it into the

slot (fig. 10-11).

• The metal bracket can be fixed into

position using the screw supplied

(fig. 12). Ensure the metal bracket is

in line with the diamond disc.

• Insert the blade guard into the notch

then tighten the screw (fig. 3).

• Put the cover (45º vertical fence)

back into position.

INSTALLATION OF THE

PROTECTIVE GUARD (Fig. 13-14)

• Unplug the tile saw from the mains

supply.

• Place the guard onto the metal

bracket (fig. 13) and fix in place using

the screw and washer. Push the

red cover cap over the nut (fig. 14).

• Cover the diamond disc with

the guard.

• Ensure that protective guard can

move freely and that it cannot touch

the disc.

• Do not over tighten the protective

guard when fixing it. The guard

should be free to rise and fall as the workpiece is pushed towards the disc.

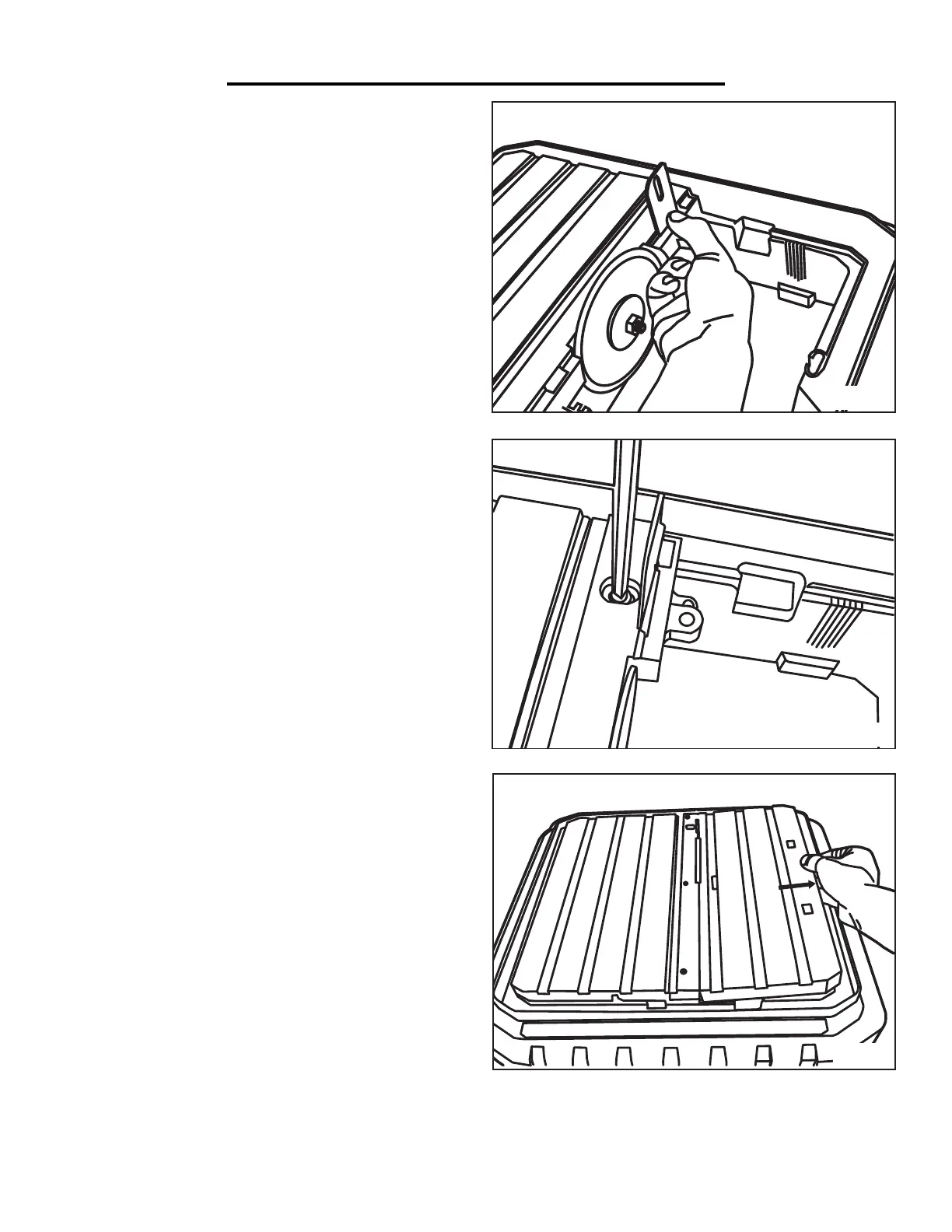

INSTALLATION OF THE PARALLEL GUIDE (Fig. 15-16)

• Unplug the tile saw from the mains supply.

• Put the parallel guide onto the working table and fix it using the plastic securing

knobs (fig. 15).

• Mitre cutting can be performed by using the mitre cutting guide. The angle can

be adjusted from 0° to 45° by unscrewing the red palstic screw.

• To perform 45° bevel cut, raise one side of the table, lever out the support and

locate the labs into the corresponding holes in the deck (fig. 16).

Ensure that the deck is correctly secured before working.

fig.10

fig.12

fig.14

fig.16

fig.9

fig.11

fig.13

fig.15

(Continued)

7. Place the metal bracket under the plastic housing

then slide it into the slot (Fig. J). Fix the metal bracket

into position using the screw and washer previously re-

moved. Ensure that the metal bracket is in line with the

diamond disc.

13

ASSEMBLY

• Replace the outer flange and nut and

tighten securely with the two spanners

provided (fig. 8). Check that both

blade flanges are in contact with the

blade.

• Unscrew the screw & washer from

the metal bracket (fig. 9).

• Put the metal bracket under the

plastic housing then slide it into the

slot (fig. 10-11).

• The metal bracket can be fixed into

position using the screw supplied

(fig. 12). Ensure the metal bracket is

in line with the diamond disc.

• Insert the blade guard into the notch

then tighten the screw (fig. 3).

• Put the cover (45º vertical fence)

back into position.

INSTALLATION OF THE

PROTECTIVE GUARD (Fig. 13-14)

• Unplug the tile saw from the mains

supply.

• Place the guard onto the metal

bracket (fig. 13) and fix in place using

the screw and washer. Push the

red cover cap over the nut (fig. 14).

• Cover the diamond disc with

the guard.

• Ensure that protective guard can

move freely and that it cannot touch

the disc.

• Do not over tighten the protective

guard when fixing it. The guard

should be free to rise and fall as the workpiece is pushed towards the disc.

INSTALLATION OF THE PARALLEL GUIDE (Fig. 15-16)

• Unplug the tile saw from the mains supply.

• Put the parallel guide onto the working table and fix it using the plastic securing

knobs (fig. 15).

• Mitre cutting can be performed by using the mitre cutting guide. The angle can

be adjusted from 0° to 45° by unscrewing the red palstic screw.

• To perform 45° bevel cut, raise one side of the table, lever out the support and

locate the labs into the corresponding holes in the deck (fig. 16).

Ensure that the deck is correctly secured before working.

fig.10

fig.12

fig.14

fig.16

fig.9

fig.11

fig.13

fig.15

8. Insert the lower blade guard back into the notch and

then tighten the screw (Fig. K).

9. Place the 45° bevel table back into position (Fig. L).

Fig. J

Fig. K

Fig. L

11

Loading...

Loading...