OPERATION

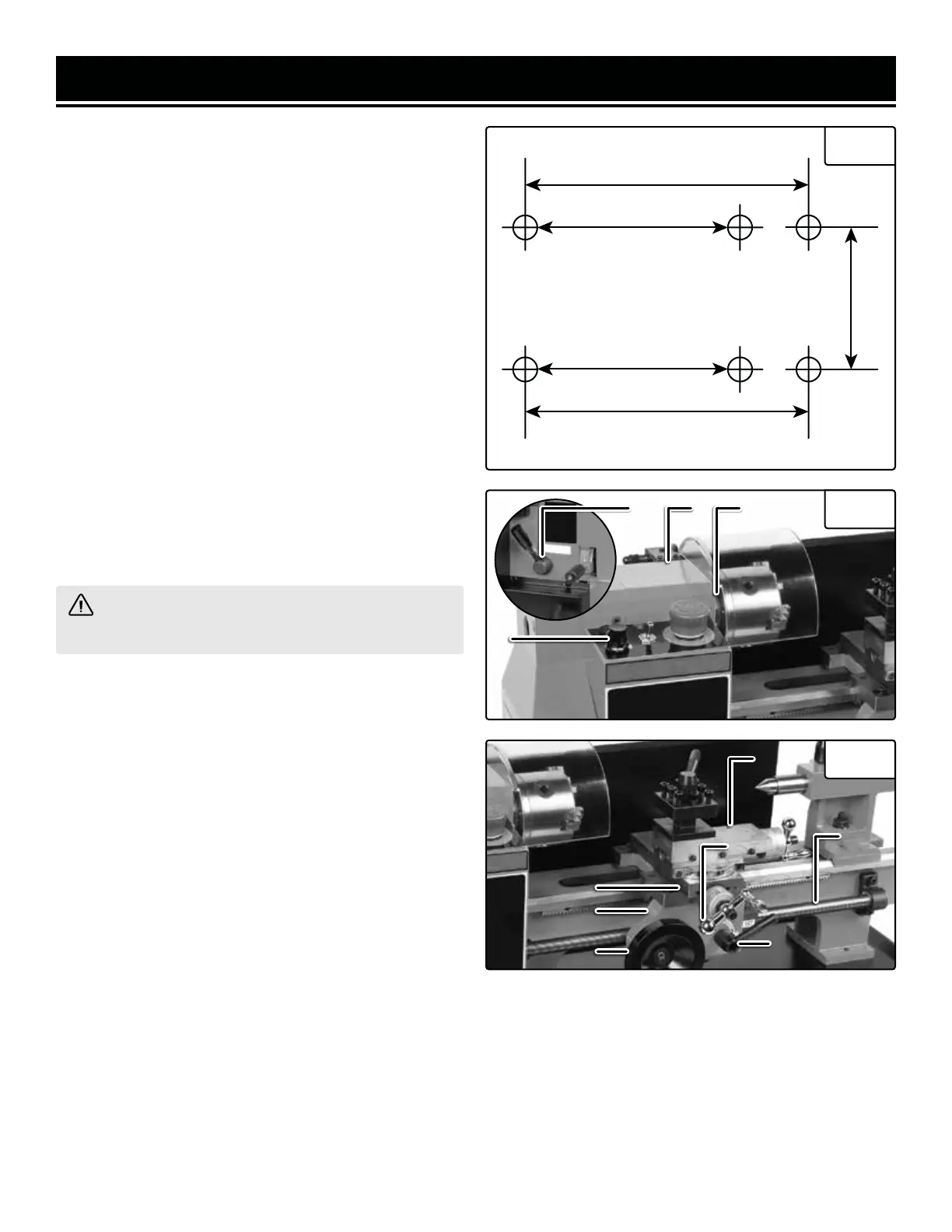

MOUNTING THE LATHE (FIG. 1)

The lathe should be mounted on a strong, heavy work-

bench. Take the necessary precautions when moving

the lathe. Assistance may be required. Bolt the machine

firmly to the workbench using the tapped holes. To do

this remove the 6mm screws securing the rubber feet

in place. Drill four 6mm (0.25-inch) clearance holes in

the worktop and find washers and 6mm screws long

enough to securely hold the unit in place.

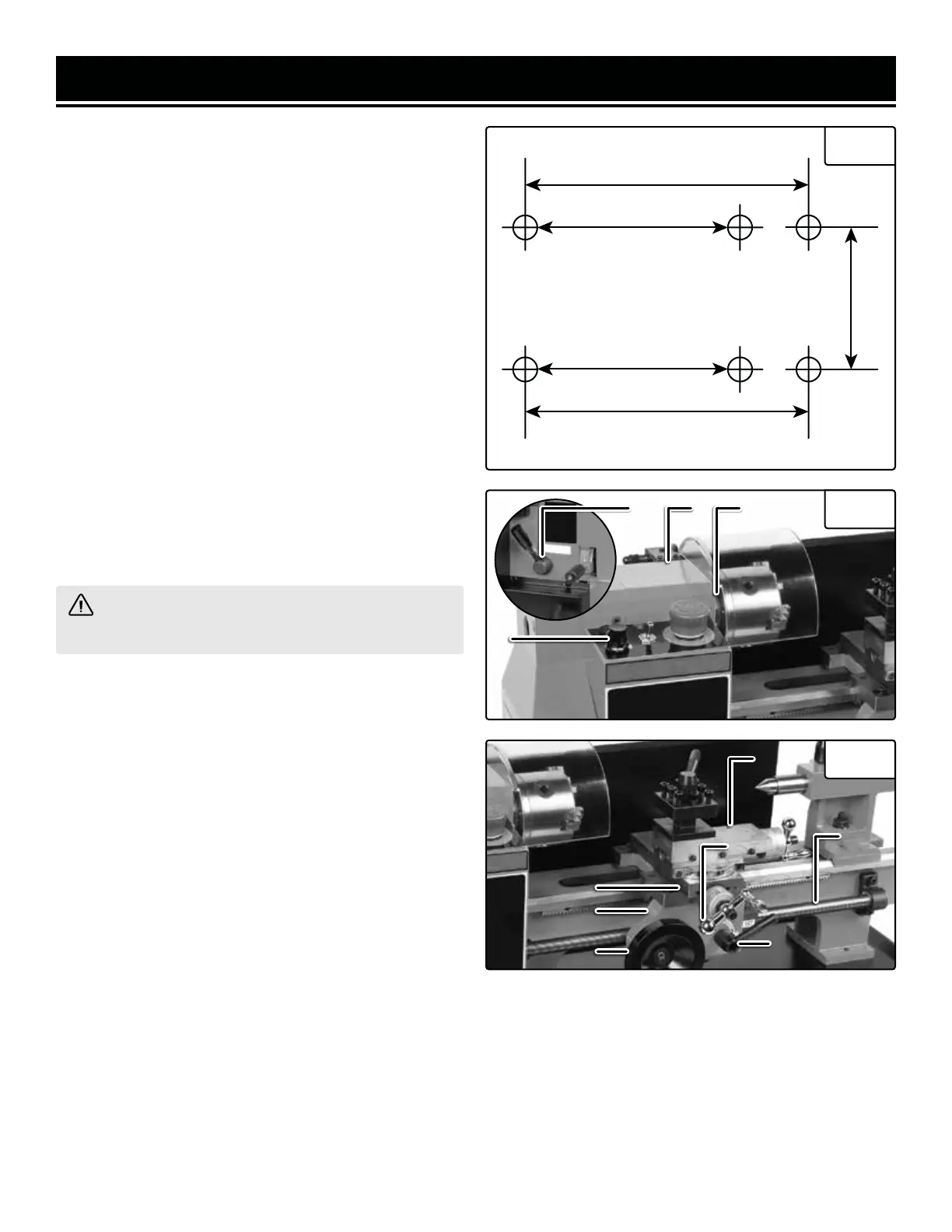

HEADSTOCK

The headstock (Fig. 2 - 1) contains the motor, pulleys

and the drive belt that turn the spindle used to create

your workpiece. The spindle (Fig. 2 - 2) has a MT3 taper

for use in conjunction with a face plate or chuck. The

spindle has a flange attached with 6 holes arranged to

mount different fixtures, such as chuck jaws and face

plates. The speed of the spindle is adjusted using the

speed control knob (Fig. 2 - 3) on the control panel. The

speed ranges can be swapped between two ranges with

the lever (Fig. 2 - 4) on the back of the headstock.

Fig. 1

Fig. 2

Fig. 3

WARNING! Do not change the speed range dur-

ing operation.

CARRIAGE

The carriage (Fig. 3 - 1) is the portion of the lathe that

moves the cross slide (Fig. 3 - 2) and compound slide

(Fig. 3 - 3) across the bed. It can be manually fed with

the handwheel (Fig. 3 - 5), or driven with the lead screw

(Fig. 3 - 4) by engaging the half nuts with the automatic

feed lever (Fig. 3 - 6).

CROSS SLIDE

The cross slide (Fig. 3 - 2) is used to move the tool

post and cutting tool across the bed, perpendicular to

the lead screw (Fig. 3 - 4) and the center axis of the

spindle. The cross slide is adjusted via a handle (Fig.

3 - 7) with precision tick marks, each indicating 0.001”.

This scale will rotate with the handle when it is turned

to feed the cross slide back and forth. Before beginning

turning, perform the following steps to adjust and zero

your cross slide:

1. Turn the handle counterclockwise to back the cross

slide about 0.015” away from your starting point, then

slowly turn the handle clockwise until the cross slide

returns to the starting position. This removes any play in

the slide and helps make the scale more accurate.

2. Hold the handle steady. With your other hand, rotate

the scale so the “0” lines up with the “0.000” mark on

the cross slide. From this point, the slide will remain ac-

curate as long as you only move it forward (toward the

splash guard on the back of the lathe).

3. Any time you back the slide away from your work-

piece, you will have to repeat steps 1 and 2 before mov-

ing the cross slide forward again for the next cut.

4

1

2

3

111

222

333

444

555

22.6 in. (575mm)

Model ML716

Model ML712

18.7 in. (475mm)

2.8 in.

(72mm)

666

11

777

Loading...

Loading...