OPERATION

COMPOUND SLIDE

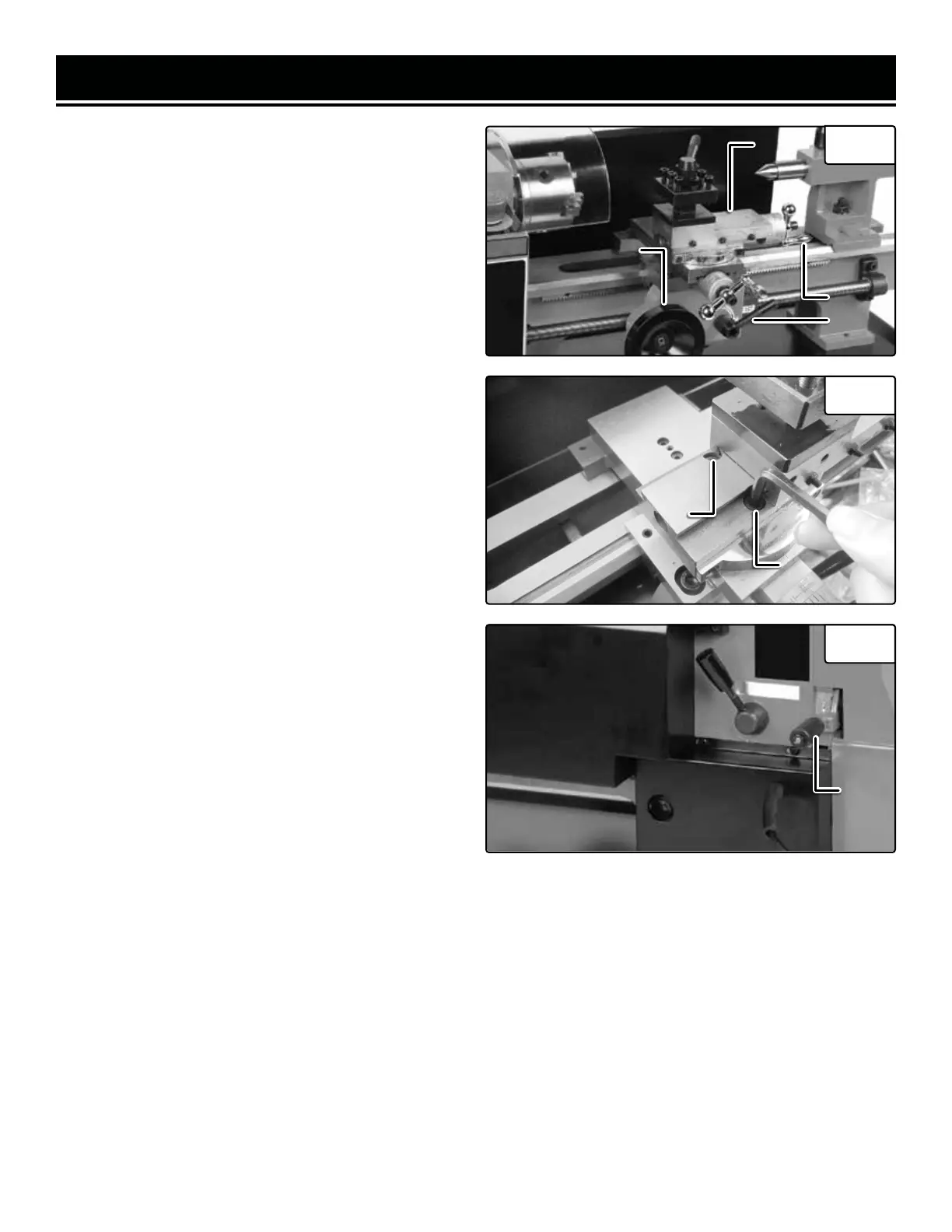

The compound slide (Fig. 4 - 1) works similarly to the

cross slide, with a small handle (Fig. 4 - 2) and a scale

with tick marks every 0.001”. The compound slide can be

fed back and forth with this handle, similar to the cross

slide. It can also be rotated to an angle of your choice

and fed back and forth along this angle.

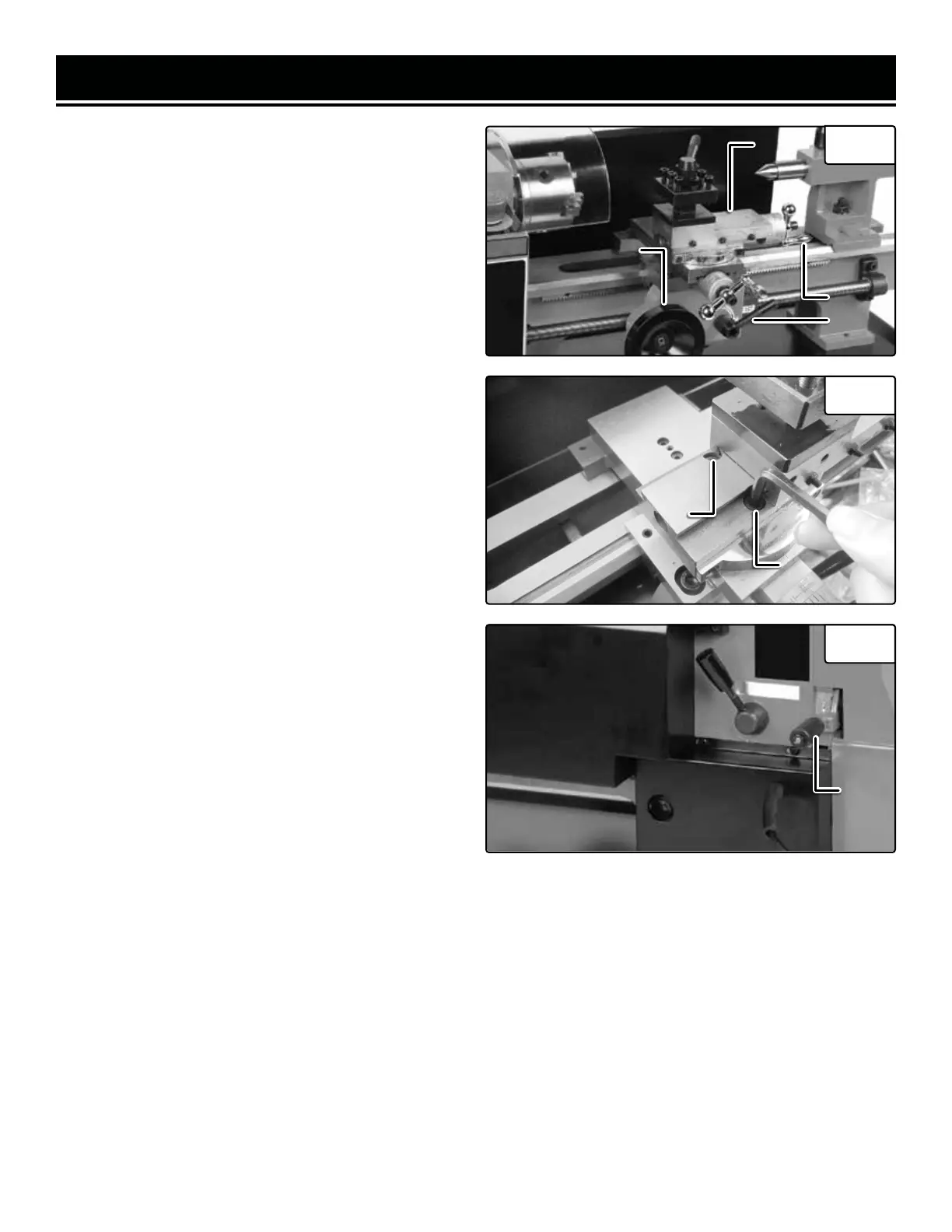

ADJUSTING THE COMPOUND SLIDE

1. Rotate the handle to move the compound slide back

and expose the two screws (Fig. 5 - 1). Loosen these two

screws with one of the included hex wrenches.

2. Rotate the compound slide to the desired angle and

retighten the bolts to lock it in place.

3. Turn the handle until your slide is at its starting point.

Then back the slide 0.015” from the starting point.

4. Slowly turn the handle to feed the slide forward until it

returns to the starting point.

5. Hold the handle in place and rotate the scale so the “0”

and “0.000” lines match and the scale is properly zeroed.

6. Repeat steps 3-5 for each cut and each time you adjust

the slide in order to get the most accurate cuts.

CARRIAGE FEED

The feed of the carriage along the axis of the spindle can

be done manually, or automatically by the lead screw and

gear train.

TO MANUALLY FEED THE CARRIAGE

Disengage the half nuts from the lead screw by pulling

UP on the feed lever (Fig. 4 - 3). Use the handlewheel on

the carriage (Fig. 4 - 4) to move it along the bed. Turning

it clockwise will move it away from the spindle and turn-

ing it counter-clockwise will move it towards the spindle.

Fig. 4 111

222

Fig. 5

111

111

333

444

Fig. 6

111

TO AUTOMATICALLY FEED THE CARRIAGE

1. Set the carriage to your starting point.

2. While the unit is still turned off, set the lead screw direction lever (Fig. 6 - 1) to either left feed or right feed, using

the label next to the lever. Choose your preferred direction based on the sticker next to the Lever.

3. Turn the lathe on and set it to the necessary RPM using the speed control knob.

4. Push the feed lever down to engage the lead screw and the automatic feed function.

5. Once the tool’s pass is finished, pull up on the lever to disengage the lead screw and the automatic feed. Move

the carriage back to the desired starting point, then push the feed lever down again and repeat.

NOTE: Increasing the spindle speed using the speed control knob will also increase the lead screw feed rate pro-

portionally.

12

Loading...

Loading...