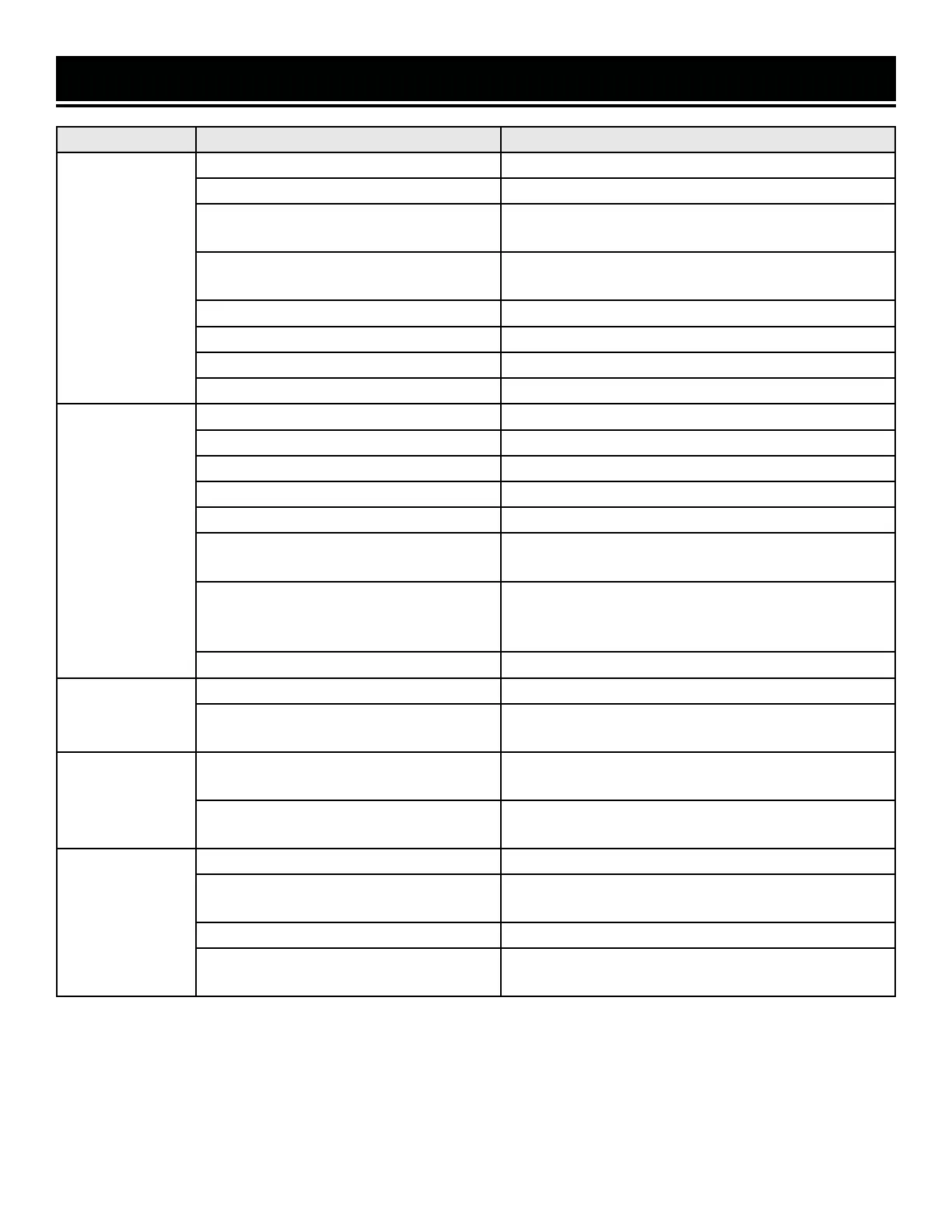

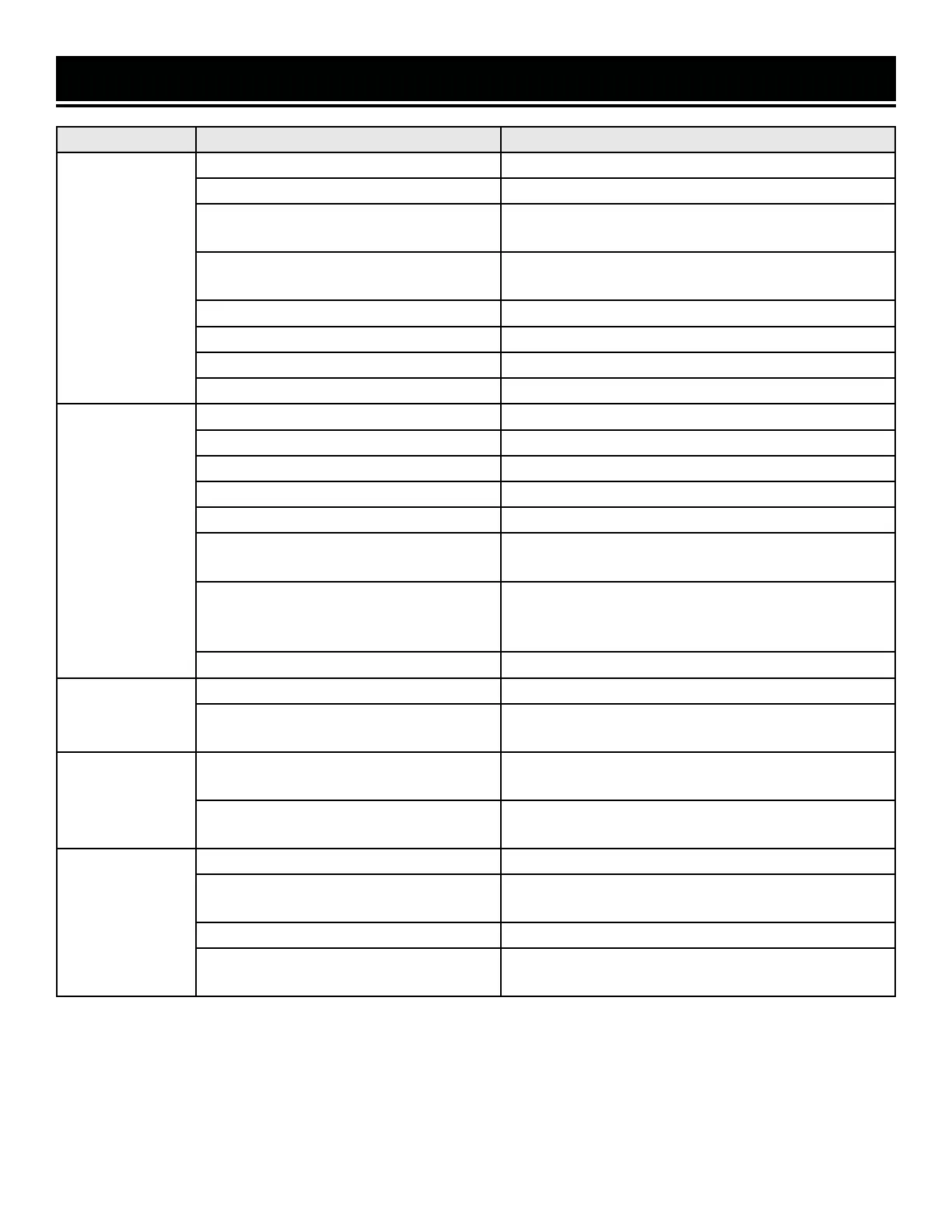

PROBLEM CAUSE SOLUTION

Machine won’t

start

1. Emergency button is stuck down. 1. Try and release the button or replace it.

2. Fuse blown. 2. Replace fuse.

3. Damaged wiring.

3. Check for any visible damage, and check with a

multimeter for correct wiring.

4. PCB board damaged.

4. Check PCB board for damage, replace if neces-

sary.

5. Motor ON/OFF switch faulty. 5. Replace switch.

6. Spindle directional switch is bad. 6. Replace switch.

7. Motor is bad. 7. Test motor, repair or replace as needed.

8. Brushes are bad. 8. Replace the brushes.

Machine stalls

out during use

1. Material of workpiece is too hard. 1. Make sure the metal isn’t too hard for the unit.

2. PCB board is faulty. 2. Inspect and replace if necessary.

3. Variable speed knob is bad. 3. Test and replace.

4. Motor brushes are bad. 4. Replace brushes.

5. Belt slipping on the pulley. 5. Tighten pulleys, replace if needed.

6. Motor bearings went bad.

6. Test by rotating the shaft manually, grinding

noise or loose shaft indicates need to replace.

7. Machine is too small for the job.

7. Make sure cutting tools are sharp, use lower feed

rate and lubricant. Decrease the spindle speed and

DOC. If problem persists the tool may be too small.

8. Spindle rotation switch is bad. 8. Test switch, replace if needed.

Grinding or

clicking noise

from headstock

1. Set screws in the pulley aren’t tight. 1. Tighten set screws.

2. Motor fan contacting cover.

2. Check fan connection, tighten if necessary, or

replace fan/cover.

Motor

overheats

1. Motor is overloaded by work being

done.

1. Reduce load on the motor, lower the RPM, cut-

ting depth and feed rates.

2.Air circulation through motor is cut

off.

2. Clean all motor vents.

Motor bogs

down during

turning

operation

1. Cut or feed rate too high. 1. Reduce cut and feed rate.

2. RPM too high for the turning being

done.

2. Reduce RPM.

3. Cutting tool is dull or damaged. 3. Sharpen or replace.

4. Gears in the gear train are too tight.

4. Adjust the gears to have a very small amount of

play. Test the chuck’s rotation by hand.

TROUBLESHOOTING GUIDDE

22

Loading...

Loading...