STARTER

MOTOR

, A

WARNING:

When

performIng

these

procedures,

position

yourself

safely

away

from

the

moving

parts

of

the

engine

in

case

the

engine

starts-up.

Also

warn

other

crew

members

of

the

danger.

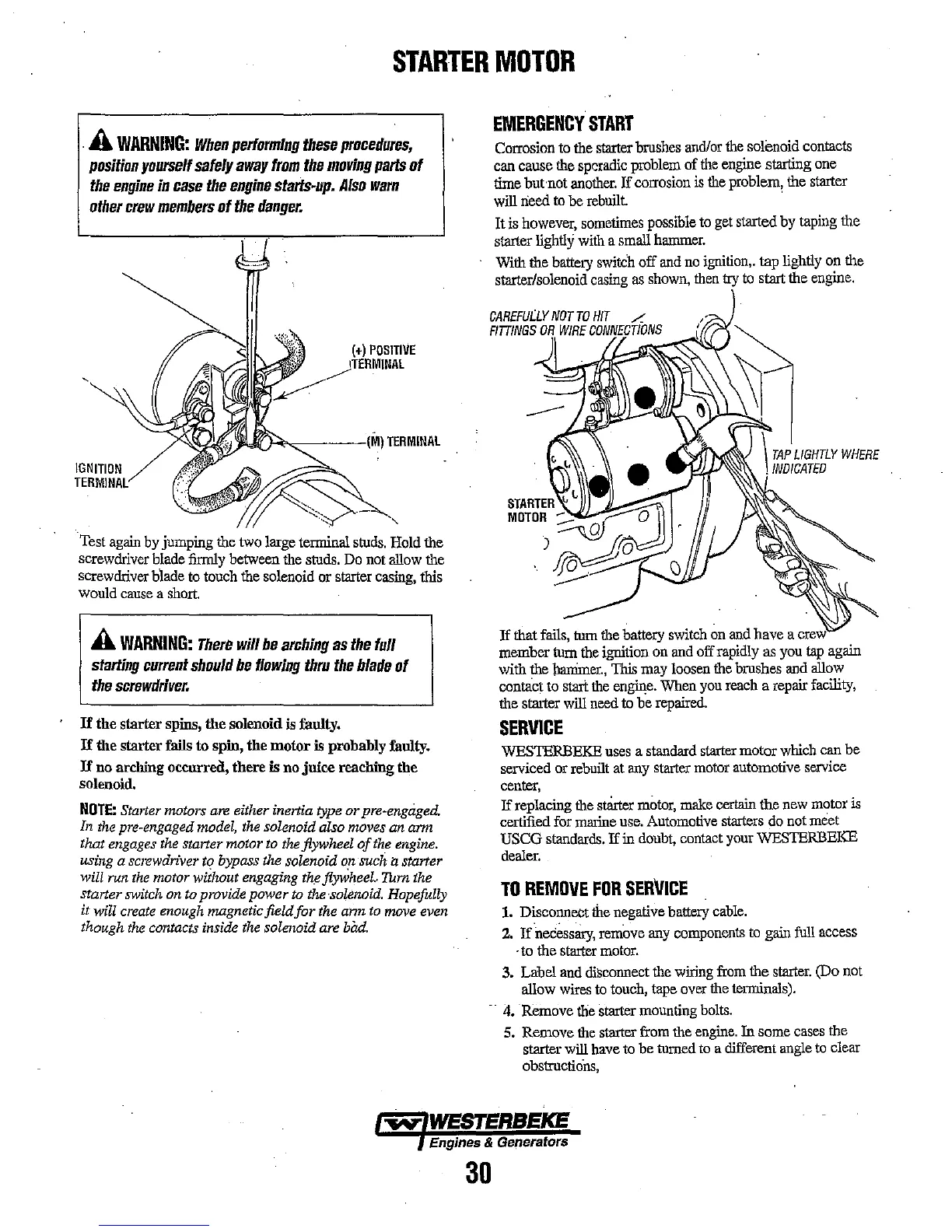

IGNITION

TERMINAL

~Ii{}_;:----(M)

TERMINAL

Test

again

by

jumping the two large terminal

studs,

Hold the

screwdriver blade

firmly

between the studs.

Do

not

allow

the

screwdriver blade

to

touch the solenoid or starter casing, this

would

cause

a

short.

A

WARNING:

There

will

be

arching

as

the

full

starting

current

should

be

flowing

thru

the

blade

of

the

screwdriver.

If

the starter spins, the solenoid

is

faulty.

If

the starter fails to spin, the motor

is

probably faulty.

If

no arching occurred, tbere is no jnice reaching the

solenoid.

NOTE:

Sta1ter

motors are either inertia type or

pre~engaged.

In

the

pre-engaged model,

the

solenoid also moves an arm

that engages

the

starter motor

to

the

flywheel

of

the engine.

using

a screwdriver

to

bypass the solenoid

on

such

11.

starter

will

run

the

nwtor wiihout engaging the

flywheel..

Thm

the

stalter switch on

to

provide power

to

the solenoid. Hopefully

it will create enough magneticfieldfor the

ann

to

nwve even

though

the

contacts inside

the

solenoid are

bad.

EMERGENCY

START

Corrosion

to

the starter brushes and/or

the

solenoid contacts

can cause the spcradic problem of

the

engine starting one

time bul'not

another.

If

corrosion

is

the problem, the starter

will

Iieed

to be rebuilt. '

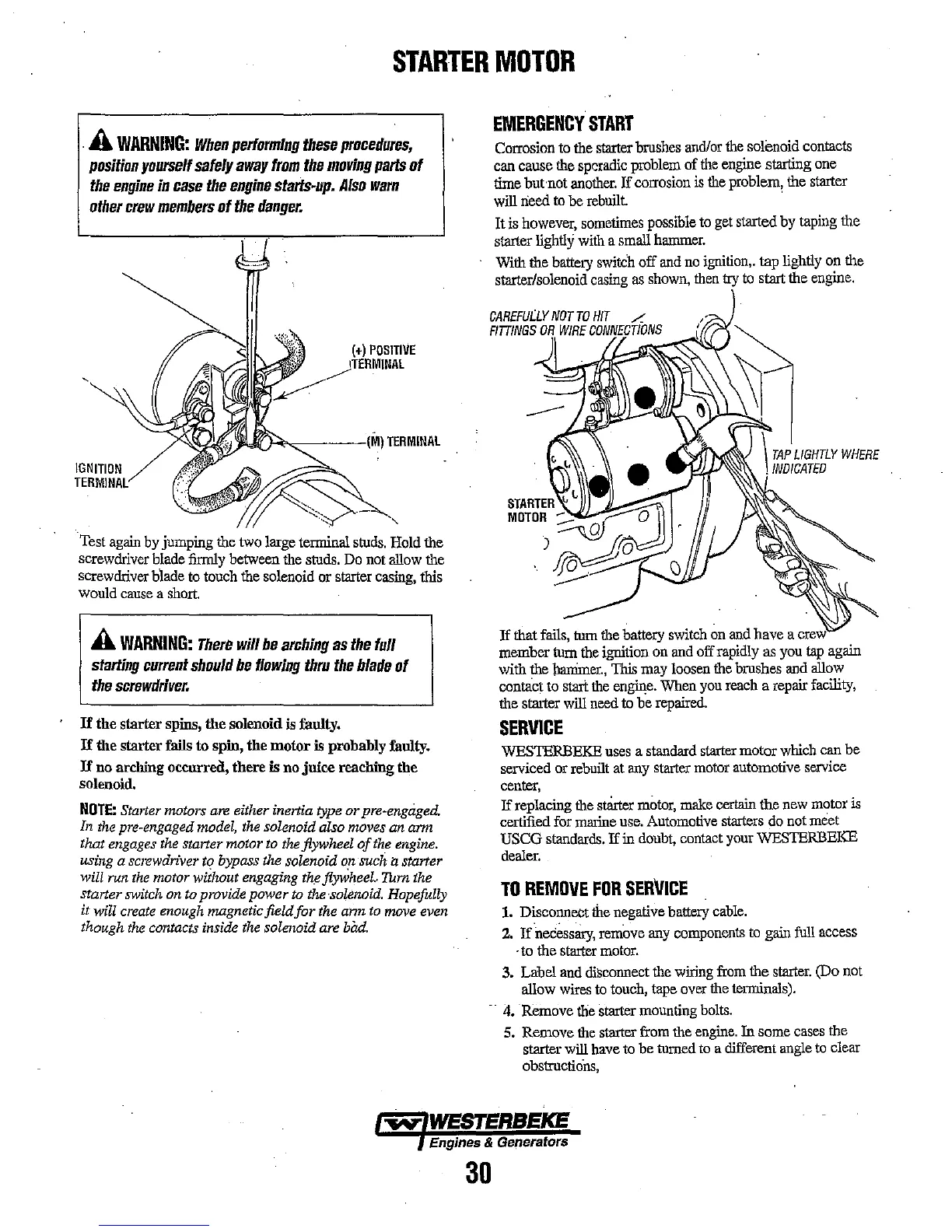

It

is however, sometimes possible

to

get

started by taping the

starter ligbtly with a small

hammer.

With the battery switch off and

no

ignition,. tap lightly

on

the

starter/solenoid casing

as

shown,

then

try

to

start the engine.

CAREFULLY

NOT

TO

HIT

~

FITTINGS

OR

WIRE

CONNECTIONS

\

~"

\

TAP

LIGHTLY

WHERE

.

INDICATED

If

that fails, tum the battery switch

on

and

have a crew

member tum

the

ignition on and off rapidly as you

tap

again

with

the

barrimer.,

This may loosen the brushes and allow

contact to start

the

engine. When

you

reach a repair facility,

the starter will need to be repaired.

SERVICE

WESTERBEKE uses a standard starter motor which can be

serviced or rebuilt at any starter motor automotive service

center,

If

replacing the st8rtef

motor,

make certain

the

new motor is

certified

for marine

use.

Automotive starters

do

not meet

USCG standards.

If

in doubt, contact your WESTERBEKE

dealer.

TO

REMOVE

FOR

SERVICE

1. Disconnect the negative battery

cable.

2.

If

'necessary,

remove any components

to

gain

full

access

. to the starter

motor.

3. Label and disconnect the wiring from the

starter.

(Do not

allow

wires

to

touch, tape over the terminals).

- 4. Remove the starter mounting bolts.

5. Remove

the

starter from the

engine.

In

some

cases

the

starter will have to be turned

to

a different angle to clear

obstructions,

~

WESTERBEKE

Engines & Generators

30

Loading...

Loading...