Injection

Pump

Inspection while

on

the

Engine

Never attempt

to

disassemble the pump unless it is

necessary.

If the pump is assumed defective, it is

recommended

to

replace the pump assembly.

Injection

Pump

Removal

1.

Disconnect the fuel injection pipes.

2. Remove the tie-rod clip cover.

3. Remove the tie-rod clip and tie-rod.

Injection Pump Disassembly

1.

Remove the stopper plate.

2. Unscrew the delivery holder. Take out the delivery

valve

and valve spring.

3. Remove the tappet roller and stopper pin.

4.

Remove the tappet, plunger spring, etc.

CAUTION

When replacing the plunger barrel, delivery

valve,

etc.,

do

not loosen the adjusting screw and

plate for each cylinder. When those parts have

been

replaced, it is necessary

to

measure

fuel

injection quantity

by

utilizing a pump tester and

cam box.

All parts removed from the pump

should be kept classified

by

cylinders and im-

mersed in clean fuel.

Injection

Pump Inspection

57

Inspection

Inspection

procedure

Criterial

Idling

speed

Measure

engine

speed.

900+

s

grpm

I)

Quickly

accelerate

No

remarkably

black·

Exhaust

smoke

color

engine

without

load.

2)

Apply

load

to

engine

smoke

exhaust

permitted.

Fuel

cut

·off

Turn

ignition

switch

to

OFF

A solenoid

acting

solenoid

from

ON.

sound.

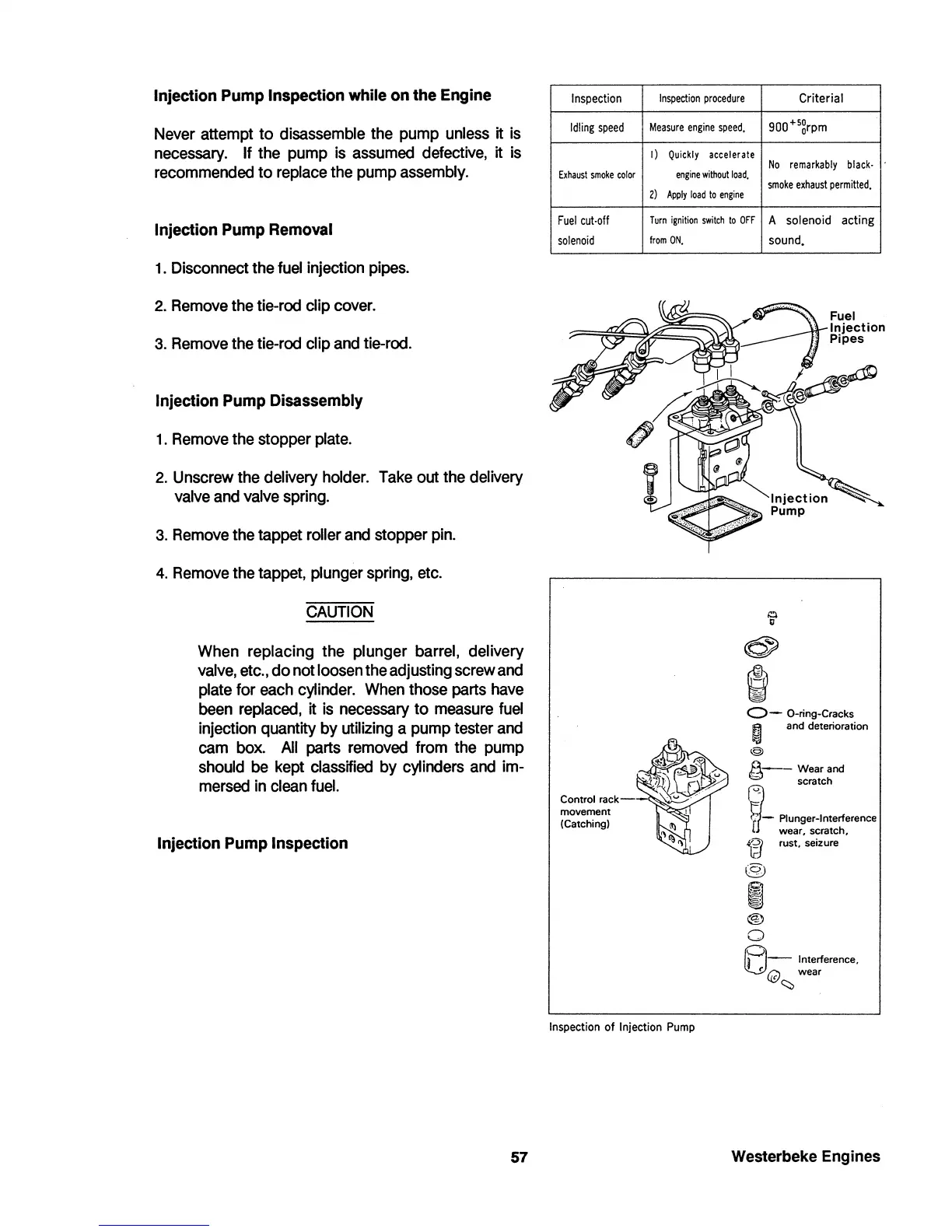

'~fn1:lction

----

IJ

Pipes

I I I

M,~,e

,~'~

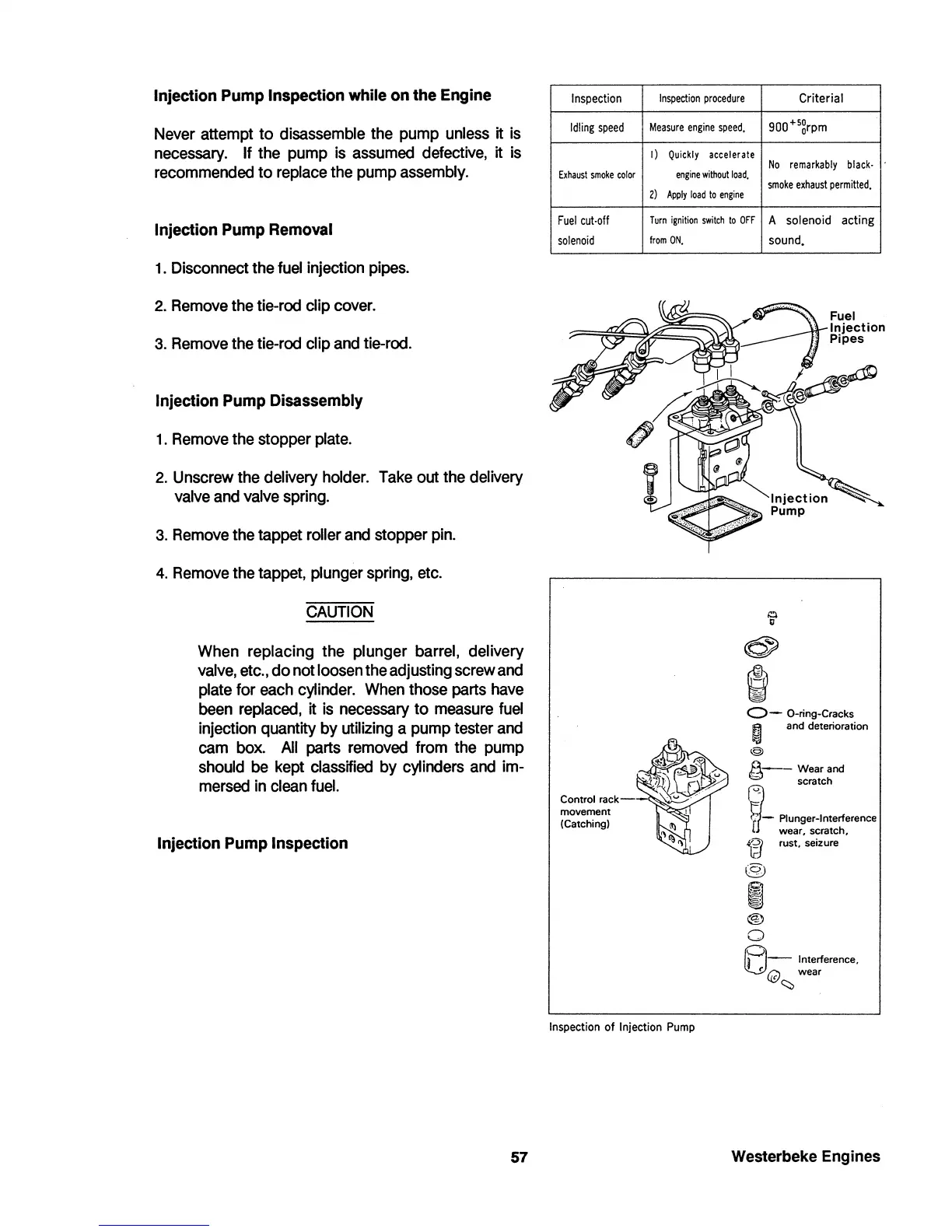

Control

rack--

movement

(Catching)

Inspection of Injection

Pump

0-

O-ring-Cracks

~

and deterioration

©

fj--

Wear and

scratch

~t~

- Plunger-Interference

11"

wear, scratch,

~

rust, seizure

I8J

I

®

o

e-Interference,

,

ri?Jc:::::,

wear

Westerbeke Engines

Loading...

Loading...